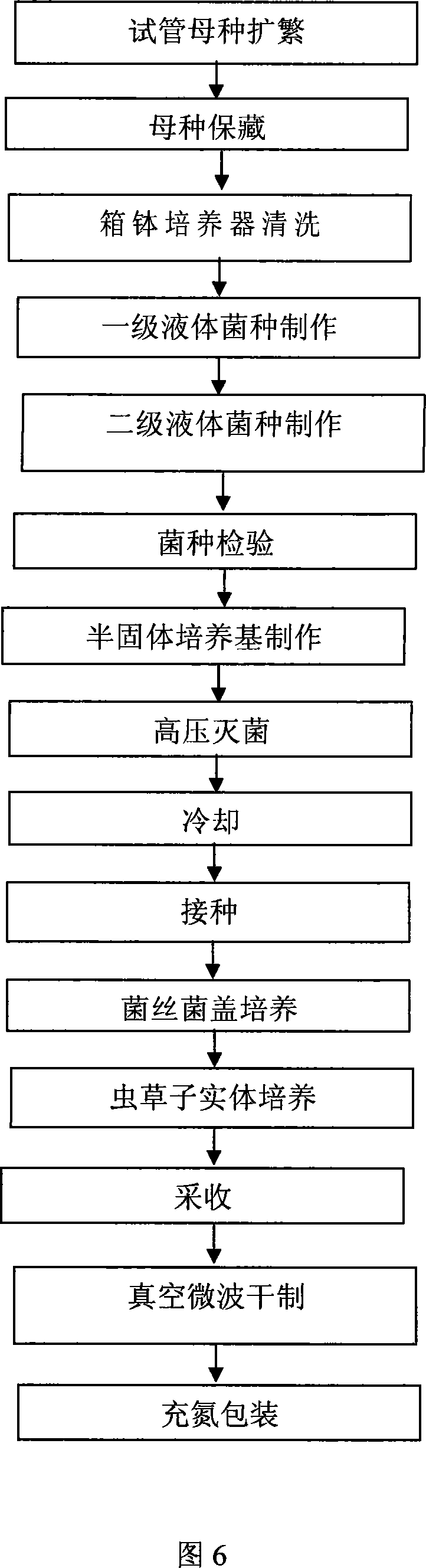

Industrial production method of cordyceps mushroom

A production method and technology for Cordyceps, applied in the field of bioengineering, can solve problems such as the inability to meet the needs of industrial production of Cordyceps mushrooms, and achieve the effects of improving biological efficiency, strong practicability, and fast color change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

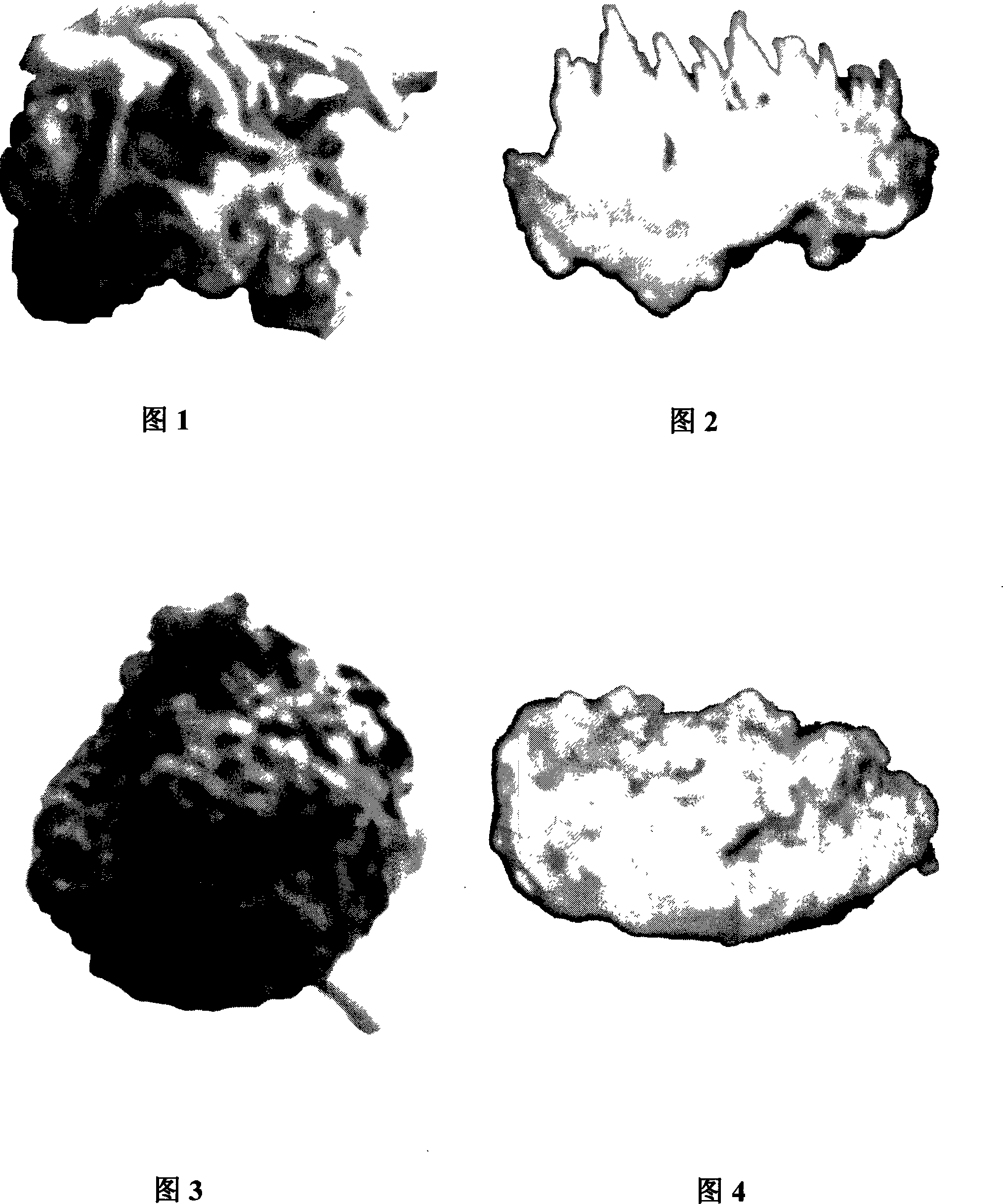

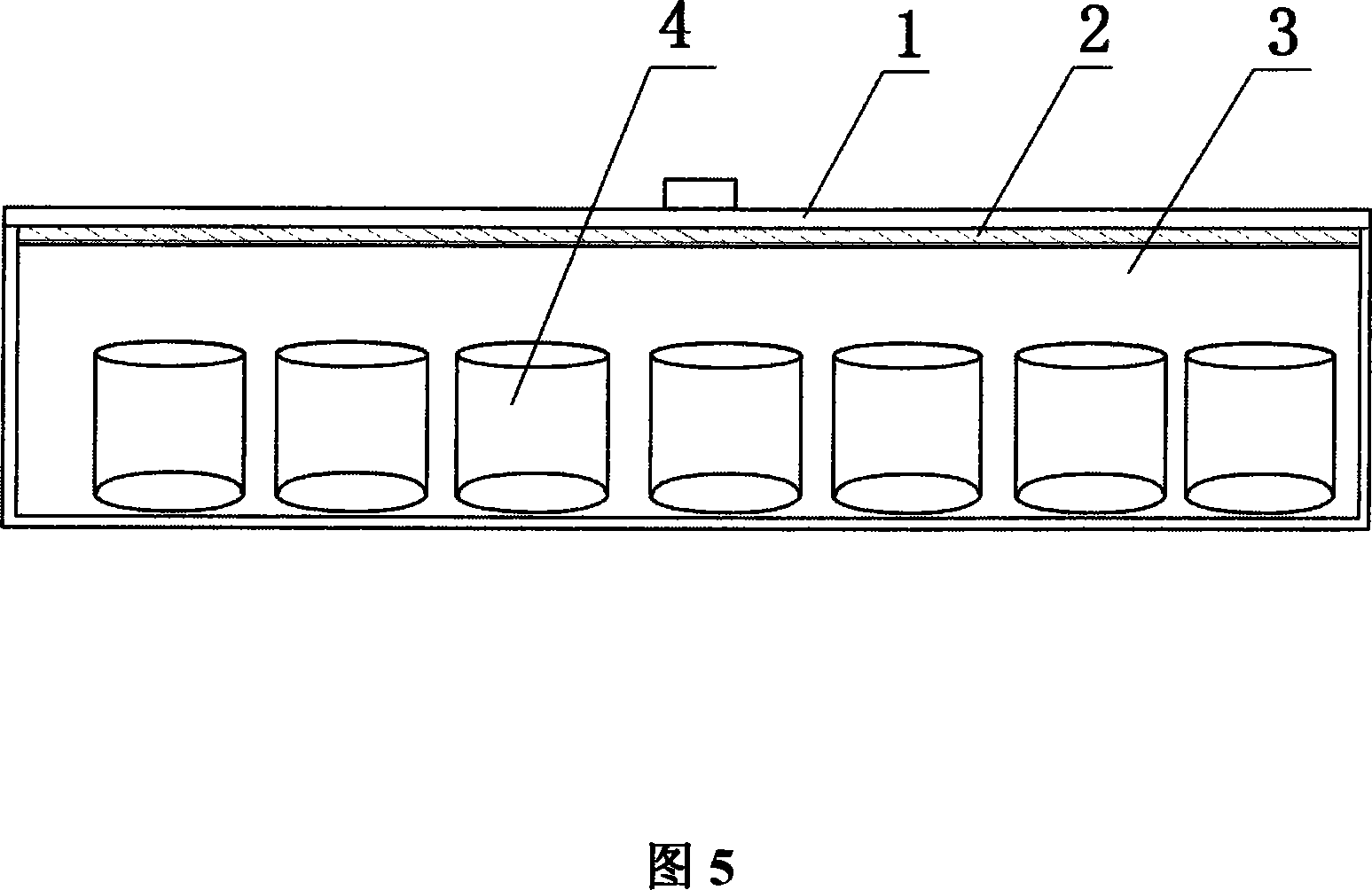

Image

Examples

Embodiment

[0045] Take 25 grams of potato starch, 100 grams of glucose, 10 grams of peptone, 2.5 grams of potassium dihydrogen phosphate, 5 grams of magnesium sulfate, 5 grams of sodium chloride, 5 grams of silkworm chrysalis powder, VB 1 100 mg, dissolve the above-mentioned raw materials in 5000 ml of boiled tap water, stir well, and divide into 25 500 ml saline bottles, each bottle contains 200 ml of liquid, seal it with a cotton plug and put it in an autoclave at 121~ Sterilize at 125°C for 30 minutes, take it out and cool it below 30°C, under aseptic conditions, insert 2 pieces of 0.5 square centimeter Cordyceps mushroom test tube parent species into each bottle, put it into the incubator and culture it statically at 25°C for 48 hours, After inspection, the bacteria bottle with no pollution and good bacteria growth is placed on a shaking incubator to maintain a temperature of 23-25 ° C, oscillating 120-150 times per minute, and vibrating for 96 hours. It is qualified by the morpholo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com