Sulfonated polysulfonamide proton exchange membrane and preparation thereof

A technology of terephthalamide and sulfonated polyphenylsulfone, which is applied in the field of polymer material science, can solve the problems of lower battery performance, poisoning, high temperature and water content requirements, and achieves high proton conductivity, broad application prospects, Chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

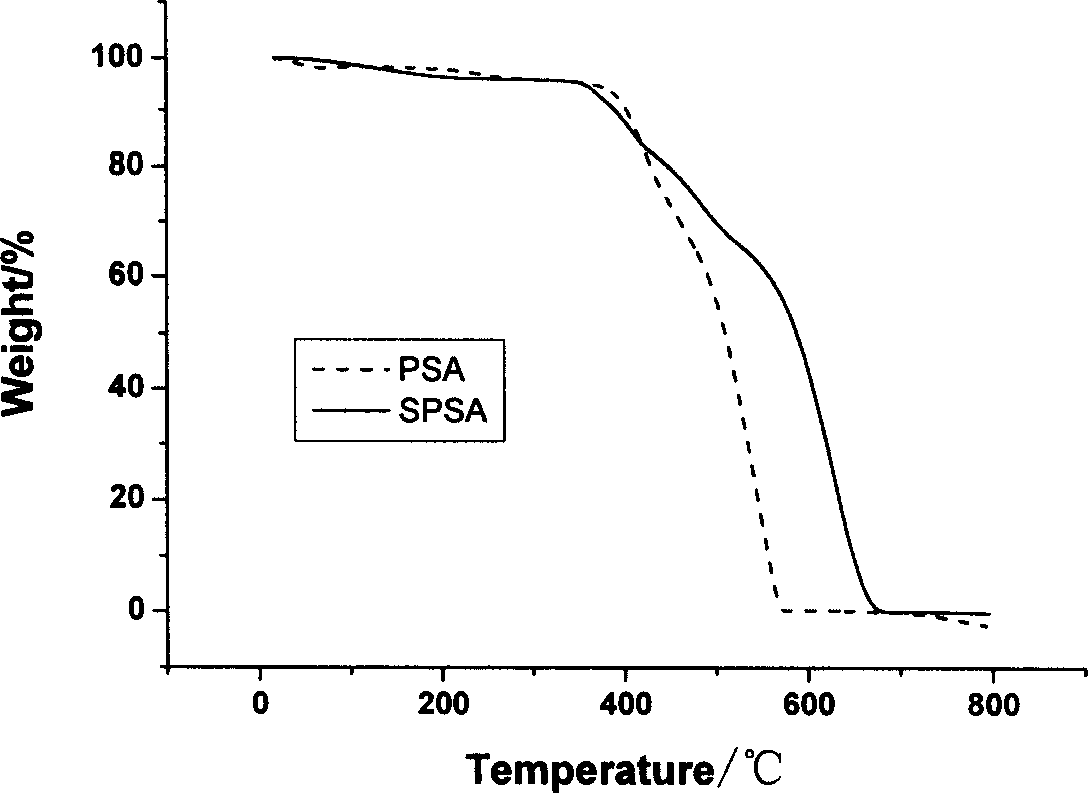

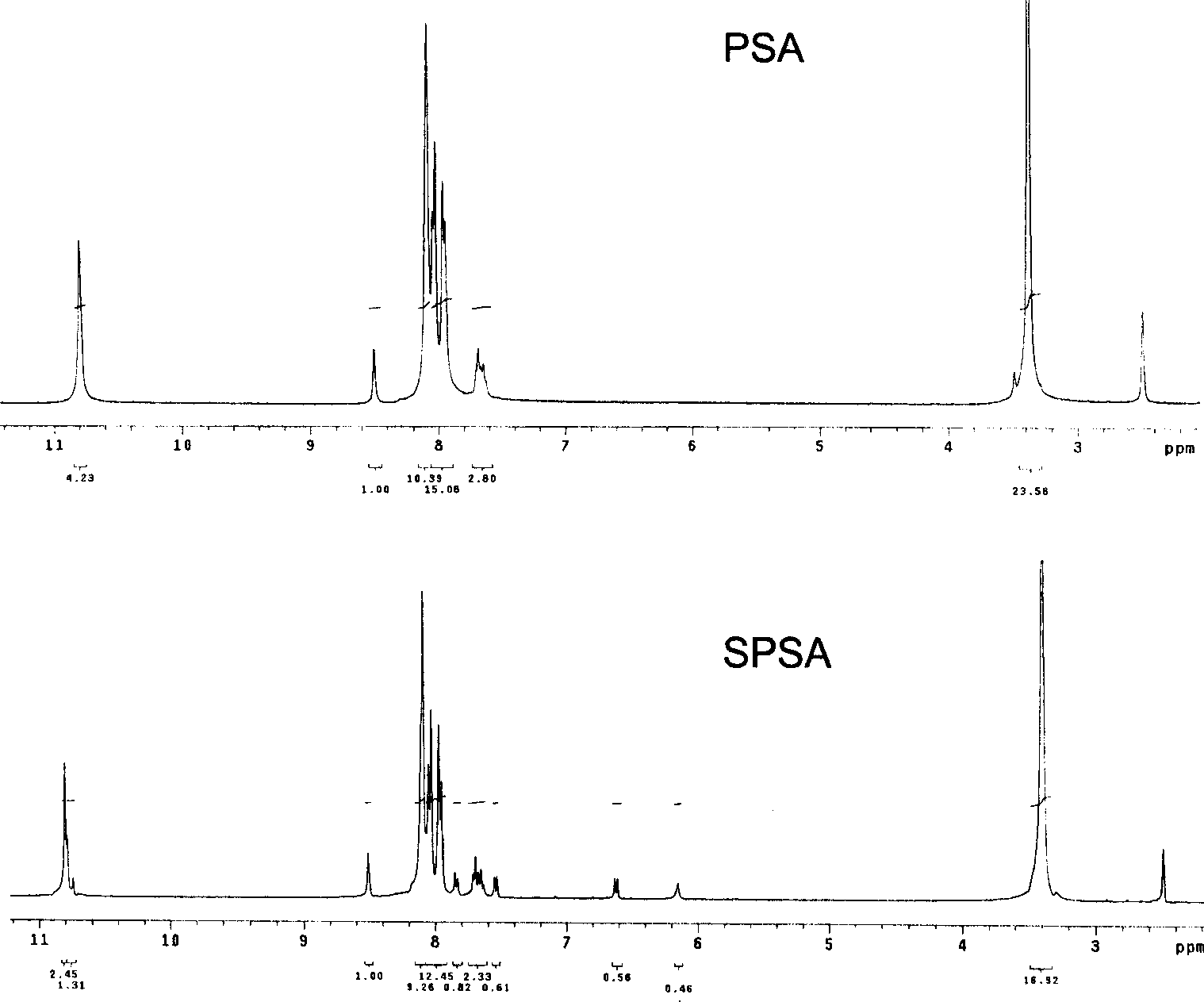

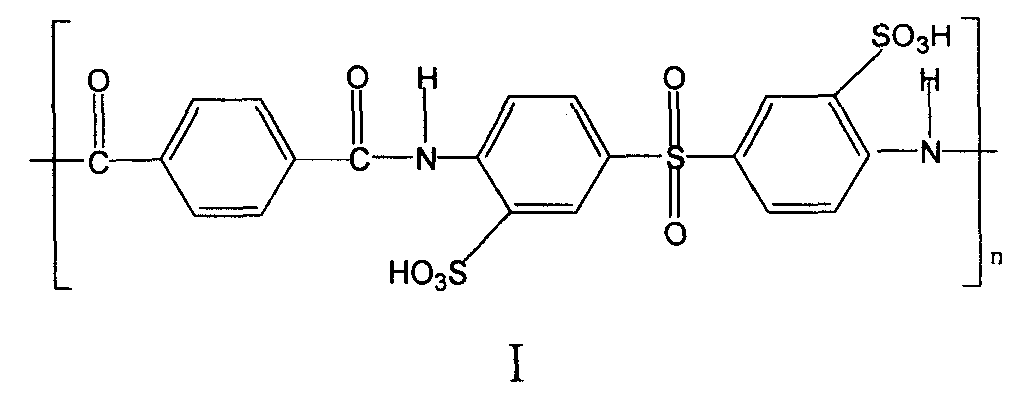

[0032] The polyphenylsulfone terephthalamide raw material was dried at 100° C. under vacuum for 1 hour, and then put into a desiccator for later use. Weigh 10g of polyphenylsulfone terephthalamide, put it into a 250mL three-necked bottle equipped with a thermometer and a stirrer, add a mixed acid of 120mL of concentrated sulfuric acid and 20mL of fuming sulfuric acid, pass high-purity nitrogen, at room temperature Stir vigorously at 25°C to reach a homogeneous solution, raise the temperature to 30°C, and react for 24 hours. Slowly pour the reaction solution into 800 mL of ice-water mixture in a thin stream to form a flocculent precipitate. After stirring for 1 hour, let it settle. Filter and wash the precipitate with deionized water several times until the pH of the filtrate is close to 7, then take out the precipitate and dry it under vacuum at 60°C for 48h. The degree of sulfonation of the product was 0.26.

Embodiment 2

[0034] Raw material processing embodiment 1. Weigh 10g of polyphenylsulfone terephthalamide, put it into a 250mL three-necked bottle equipped with a thermometer and a stirrer, add 100mL of concentrated sulfuric acid and 40mL of fuming sulfuric acid mixed acid, pass high-purity nitrogen, at room temperature Stir vigorously at 25°C to reach a homogeneous solution, raise the temperature to 80°C, and react for 8 hours. Slowly pour the reaction solution into 800mL of ice-water mixture in a thin stream to form a flocculent precipitate. After stirring for 1 hour, let it settle. Filter and wash the precipitate with deionized water several times until the pH of the filtrate is close to 7, then take out the precipitate and dry it under vacuum at 60°C for 48h. The degree of sulfonation of the product was 1.03.

Embodiment 3

[0036] Raw material processing embodiment 1. Weigh 10g of polyphenylsulfone terephthalamide, put it into a 250mL three-necked bottle equipped with a thermometer and a stirrer, add a mixed acid of 100mL of concentrated sulfuric acid and 50mL of fuming sulfuric acid, and pass high-purity nitrogen gas at room temperature Stir vigorously at 25°C to reach a homogeneous solution, raise the temperature to 100°C, and react for 12 hours. Slowly pour the reaction solution into 800mL of ice-water mixture in a trickle to form a flocculent precipitate. After stirring for 1 hour, let it settle. Filter and wash the precipitate with deionized water several times until the pH of the filtrate is close to 7, then take out the precipitate and dry it under vacuum at 60°C for 48h. The degree of sulfonation of the product was 1.91.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com