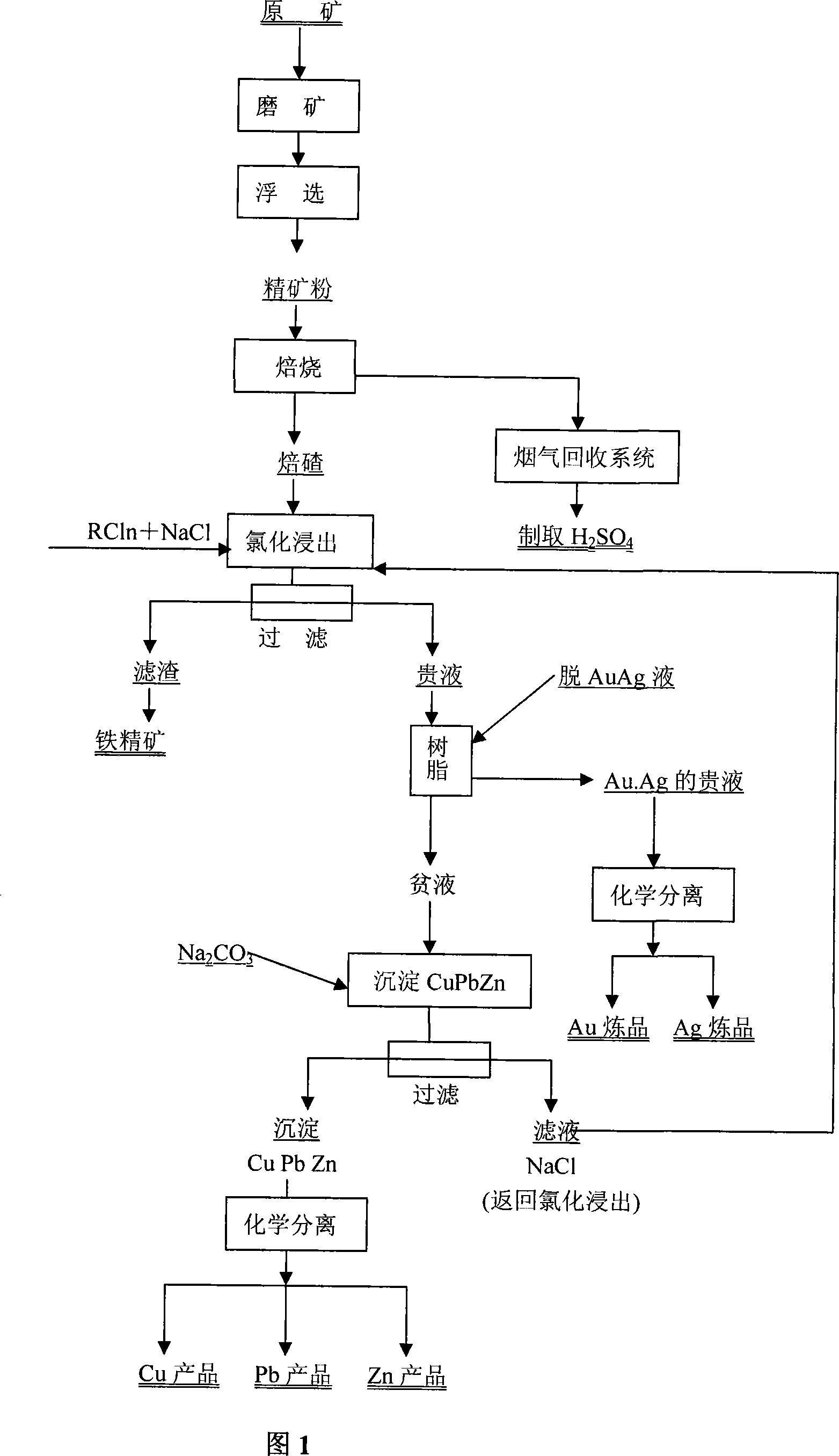

Integrated utilization technique for multi-metal ore containing gold and silver by chlorine carrier chlorination method

A chlorination method and process technology, applied in the field of metallurgy, can solve problems such as high economic cost, heavy environmental pollution, and low technical indicators, and achieve the effects of good release performance, good adsorption selectivity, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A gold smelter purchases gold concentrate powder from various mines as raw materials. The plant mixes and processes 200 tons of gold concentrate powder per day, goes to the fluidized bed furnace for sulfation roasting, and recovers flue gas to produce sulfuric acid. The baked ballast is first immersed in copper under the condition of heating with dilute sulfuric acid (>80°C), and separated by a belt filter. The filtrate is sent to produce electrolytic copper. Filter residue with NaOH+Na 2 CO 3 After adjustment, two-stage cyanidation leaching of gold and silver is carried out. The first stage of cyanidation is 24 hours, and the second stage of cyanidation is carried out for 12 hours after the grinding operation is added in the middle to reach a fineness of 325 mesh. The immersion gold rate reaches 98%, and the immersion silver rate is about 70%. The thickener is separated, and the gold and silver are recovered from the precious liquid by zinc powder replacement meth...

Embodiment 2

[0041] The flotation gold concentrate powder of a gold mine, the gold concentrate powder of this mine has been tested for gold leaching by cyanide, and the effect is not good, so there is no gold extraction operation. The ore belongs to the low-sulfur pyrrhotite-type gold deposit, and contains a small amount of arsenic and graphite carbon, so the low-temperature chlorination roasting pretreatment scheme is selected. Take 200Kg flotation gold concentrate powder, add 15% sodium chloride powder, roast at 350°C-400°C for 6 hours, leave the kiln and let it cool down to become gray-red calcined sand.

[0042] The leaching of low-temperature chlorinated calcine is carried out in two steps. The first step is leaching with clear water. The experimental method is to take 100Kg of calcined sand and put it in the soaking bucket of Dashuo material, add it to soak in clean water according to the solid-liquid ratio S:L=1:4, start the mixer to stir and soak for 4 hours, and then use a filter ...

Embodiment 3

[0052] Silver concentrate powder from a silver mine. Containing silver (Ag) 4160 (g / t), Au36.4 (g / t), Pb2.80 (%), Zn0.96 (%) Cu0.51 (%), Cd0.13 (%), C ( Graphite carbon) > 4 (%). The mine was once identified as a difficult-to-smelt silver mine, mainly due to the influence of graphite carbon, which is not suitable for wet cyanidation to extract silver, so a pyro-smelting process was designed. Its pyrotechnic process involves ① roasting concentrate in slag furnace (flue gas to sulfuric acid) ② slag is collected in blast furnace with lead rain to collect gold and silver ③ crude lead is added sulfur to remove copper and alkali to remove arsenic and tin in refining pot Antimony ④ adding metal zinc to enrich gold and silver into a silver-zinc shell ⑤ vacuum steaming zinc in a zinc pot ⑥ ash blowing oxidation of noble lead to remove lead, ⑦ electrolytic separation of gold and silver, etc. It can be seen that the fire process is lengthy, many links, labor-intensive, and environment-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com