Micro electrolysis disinfecting preparation and preparing method thereof

A technology for disinfectants and electrolyzers, applied in the directions of disinfectants, botanical equipment and methods, biocides, etc., can solve the problems of high equipment manufacturing and operating costs, large power consumption, and tap water impact, and achieve equipment manufacturing and production. The effect of low operation cost, lower production operation cost and lower equipment manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

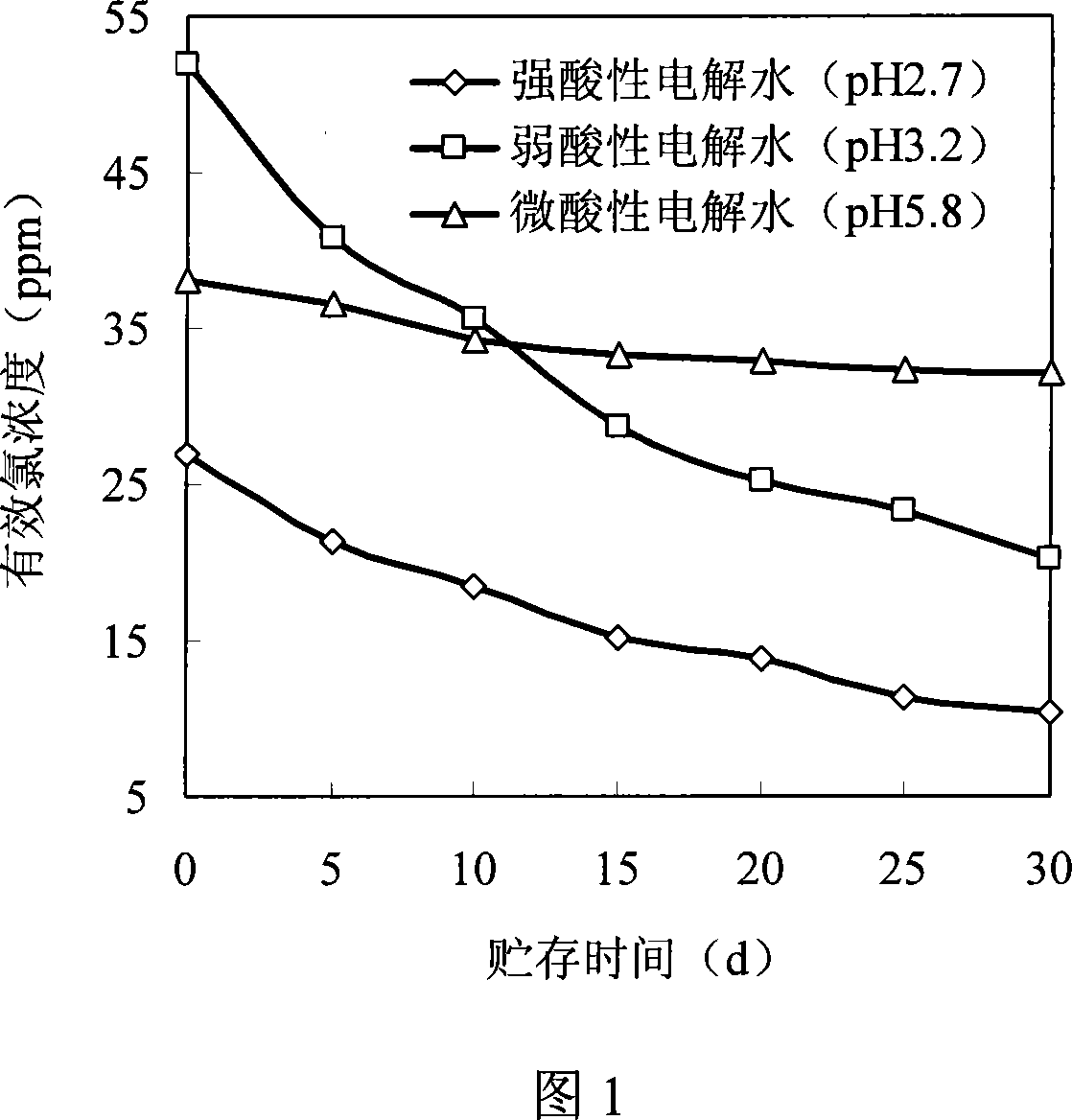

[0019] Preparation of Micro-electrolysis Bactericidal Disinfectant

[0020] Add 0.2ml of hydrochloric acid with a concentration of 36-38% into 1L of pretreated tap water and mix evenly (the molar concentration is 2.4mM) to obtain a mixed solution; after testing, the conductivity of the mixed solution is 75mS / cm, pH5.75 , ORP 535.7mV, then add the mixture to a volume of 33×15×3.5cm 3 In a diaphragmless electrolyzer with cathode and anode electrodes (manufactured by Shenyang Dongyu Xinboer Technology Co., Ltd.), the electrode plate (29.2×14cm) is made of platinum-plated iridium and ruthenium on titanium, and the distance between the two plates is 0.4cm. Under the condition of 20A electric current, electrolyze for 10min, get pH 6.07, ORP 333.3mV, available chlorine concentration is 15ppm micro-electrolytic bactericidal disinfectant. What this embodiment adopts is intermittent electrolysis mode.

Embodiment 2

[0022] Preparation of Micro-electrolysis Bactericidal Disinfectant

[0023] Mix hydrochloric acid and pretreated tap water to form a hydrochloric acid solution with a molar concentration of 3mM (hydrochloric acid + pretreated tap water, conductivity 82mS / cm, pH4.52, ORP 447.9mV), and The flow rate is continuously added and the volume is 35×20×2.5cm 3 In a diaphragmless electrolyzer with cathode and anode electrodes (produced by Shenyang Dongyu Xinboer Technology Co., Ltd.), the electrode plate (30×16cm) is made of platinum-plated titanium antimony alloy, and the distance between the two plates is 0.4cm. Under electrolysis, obtain pH5.81, ORP 690.0mV, available chlorine concentration is the micro-electrolysis sterilizing disinfectant of 38ppm.

Embodiment 3

[0025] Bactericidal test of microelectrolytic bactericidal disinfectant on pathogenic Salmonella and Escherichia coli

[0026]The bactericidal disinfectant prepared in Example 1 was used to carry out bactericidal tests on the main pathogenic bacteria Salmonella (Salmonella Pullorum and Salmonella enteritidi) and Escherichia coli (Escherichia coli). The strains and medium were purchased from Beijing Haidian Zhonghai Animal Health Technology Company. Including the following steps

[0027] (1) Preparation of bacterial suspension

[0028] The freeze-dried strains were activated, inoculated on tryptone soybean agar medium, incubated at a constant temperature of 37°C for 24 hours, then inoculated on the inclined surface of the test tube and stored in the refrigerator for later use.

[0029] Pick a small amount of bacterial lawn from the slant surface of each strain after activation and inoculate it on a tryptone soybean agar plate by streaking method, culture at a constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com