Universal synthesis method for porous hollow metallic oxide

An oxide and hollow technology, applied in the field of preparation of inorganic non-metallic materials, can solve the problems of complex process, many steps, unfavorable for industrial scale up, etc., and achieve the effects of low preparation cost, good dispersibility, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

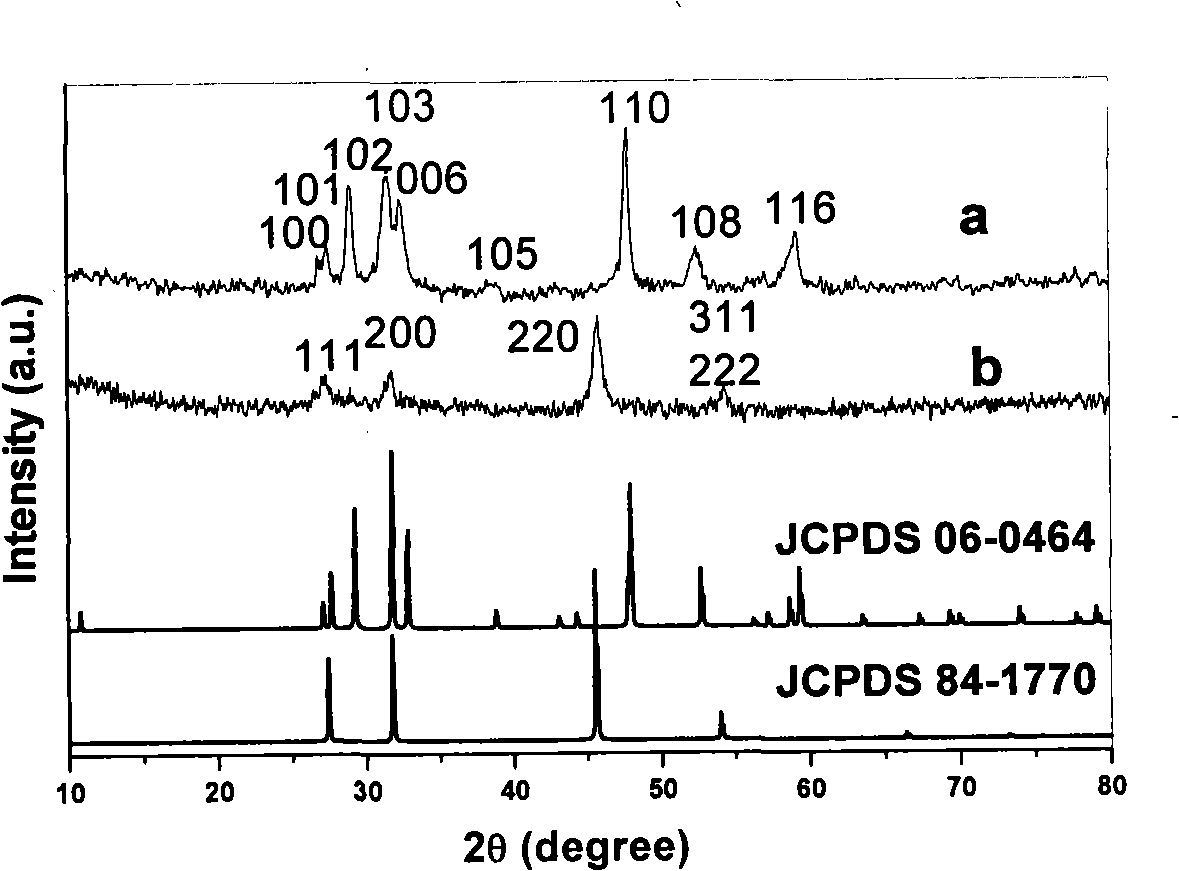

[0023] 1.2~4.8g Cu(NO 3 ) 2 ·3H 2 O was added to the reaction vessel, 25 mL of dimethyl sulfoxide was slowly added at room temperature, and the reaction was stirred at a stirring speed of 120 rpm for 10 minutes. After the dissolution is complete, 0-2 g of polyvinylpyrrolidone (Mw=80000) and 0.38-1.52 g of thiourea are added respectively. After the solution has completely dissolved and turned into a clear solution, put it into a 30mL autoclave, heat up to 80-180°C at a heating rate of 5°C / min, and then react for 5-48h. Cool naturally at room temperature after the reaction is complete, centrifugally filter the obtained black solution, wash with distilled water and absolute ethanol, and dry at 60° C. for 4 hours to obtain a cake-shaped copper sulfide precursor. The temperature was raised to 400°C at a heating rate of 20°C / min and then calcined for 4 hours to obtain a porous cake-like CuO hollow structure. It has been determined that its average diameter is about 1.7 μm and it...

Embodiment 2

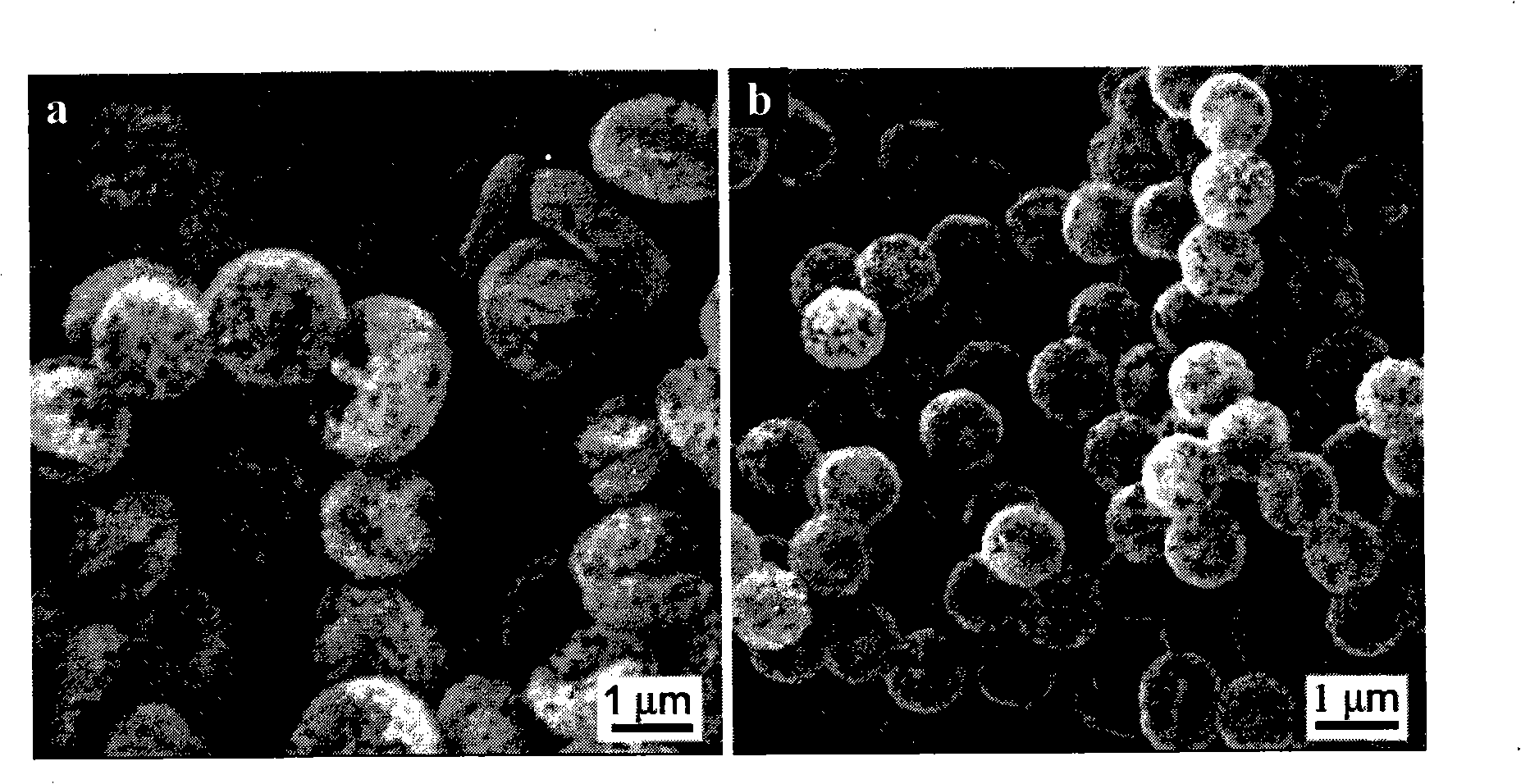

[0025] 1.2~4.8g Cu(NO 3) 2 ·3H 2 O was added to the reaction vessel, 25 mL of dimethylformamide was slowly added at room temperature, and the reaction was stirred at a stirring speed of 120 rpm for 10 minutes. After the dissolution is complete, 0-2 g of polyvinylpyrrolidone (Mw=80000) and 0.38-1.52 g of thiourea are added respectively. After the solution has completely dissolved and turned into a clear solution, put it into a 30mL autoclave, heat up to 80-180°C at a heating rate of 5°C / min, and then react for 5-48h. Cool naturally at room temperature after the reaction is complete, centrifugally filter the obtained black solution, wash with distilled water and absolute ethanol, and dry at 60° C. for 4 hours to obtain a spherical cuprous sulfide precursor. The temperature was raised to 400°C at a heating rate of 20°C / min and then calcined for 4 hours to obtain a porous spherical CuO hollow structure. Its average diameter was determined to be about 900nm.

Embodiment 3

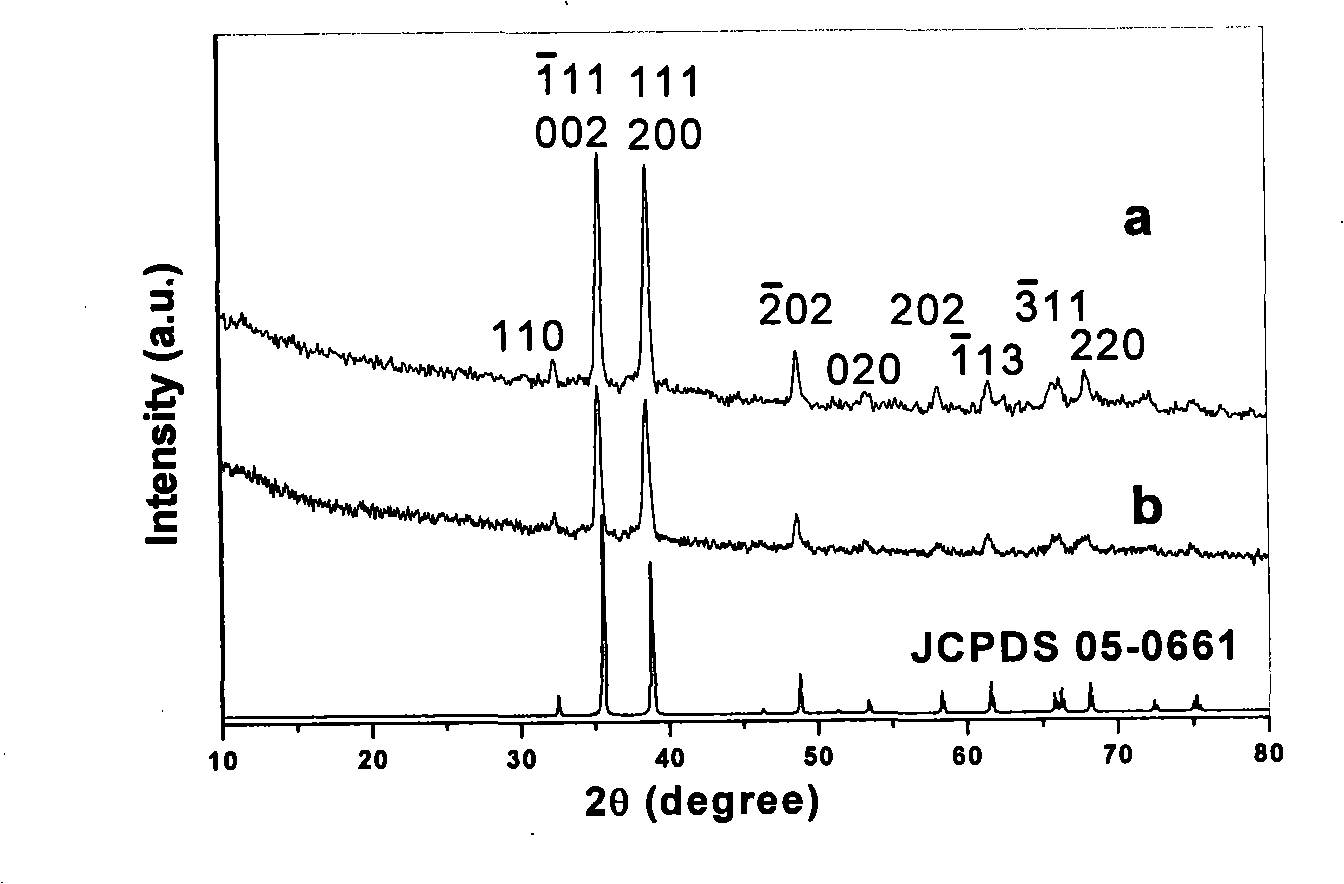

[0027] 1.2~4.8g Cu(NO 3 ) 2 ·3H 2 O was added to the reaction vessel, 25 mL of formamide was slowly added at room temperature, and the reaction was stirred at a stirring speed of 120 rpm for 10 minutes. After the dissolution is complete, 0-2 g of polyvinylpyrrolidone (Mw=80000) and 0.8-2 g of sodium selenite are added respectively. After the dissolution is complete, put it into a 30mL autoclave, raise the temperature to 80-180°C at a heating rate of 5°C / min, and then react for 5-48h. Cool naturally at room temperature after the reaction is complete, filter the obtained solution, wash with distilled water and absolute ethanol, and dry at 60°C for 4 hours to obtain a fibrous copper selenide precursor. The temperature was raised to 400° C. at a heating rate of 20° C. / min and then calcined for 4 hours to obtain porous CuO hollow fibers. It has been determined that its diameter is 3-5 μm and its length is 30-40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com