Alpha-cyclodextrin glucosyl transferase gene clone and expression

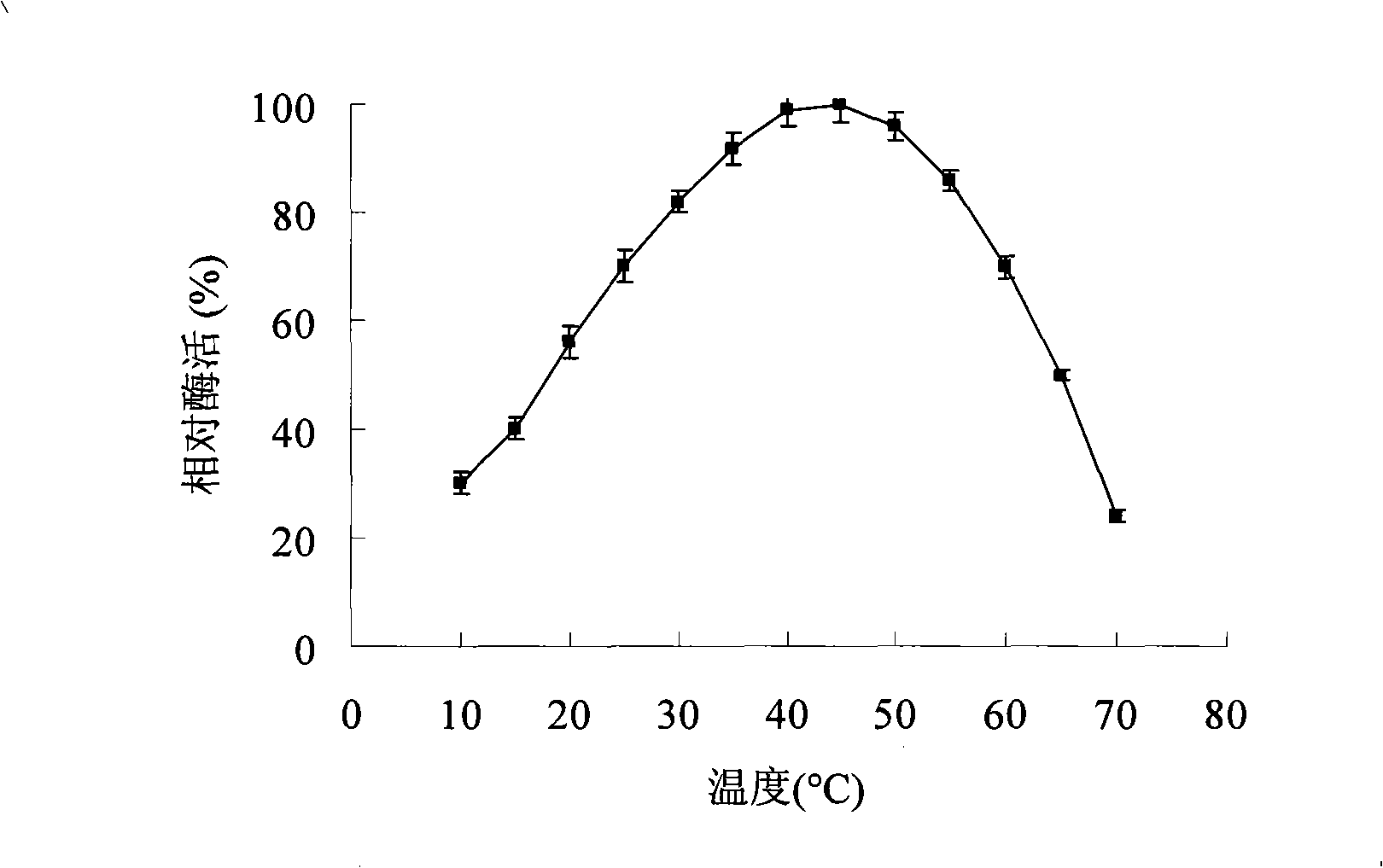

A glucosyl and cyclodextrin technology, which is applied in the fields of enzyme genetic engineering and enzyme engineering, can solve the problems of unfavorable recombinant α-CGT enzyme recovery and use, and achieve the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example illustrates the extraction of total DNA from Paenibacillus macerans JFB05-01.

[0046] The P.macerans JFB05-01 strain was cultured in LB liquid medium (peptone 10g / L, yeast extract 5g / L, NaCl 10g / L) for 2 days, collected by centrifugation at 10,000rpm, washed with sterile water, and the collected precipitate was suspended in 500μL Add 15 μL of lysozyme to Tris-EDTA (trishydroxymethylaminomethane-ethylenediaminetetraacetic acid) buffer, incubate at 37°C for 30 minutes, then add 5 μL of RNase, incubate at 37°C for 30 minutes, add 30 μL of 10% SDS (dodecane sodium sulfate) and 15 μL proteinase K, incubated at 37°C for 60 min, added 100 μL NaCl (5M) and 80 μL CTAB (cetyltrimethylammonium bromide), incubated at 65°C for 20 min, and incubated with 700 μL of phenol: chloroform: iso Extract with a mixed solvent of amyl alcohol at a volume ratio of 25:24:1, centrifuge at 10,000 rpm, extract the supernatant with 700 μL of chloroform:isoamyl alcohol at a volume ratio ...

Embodiment 2

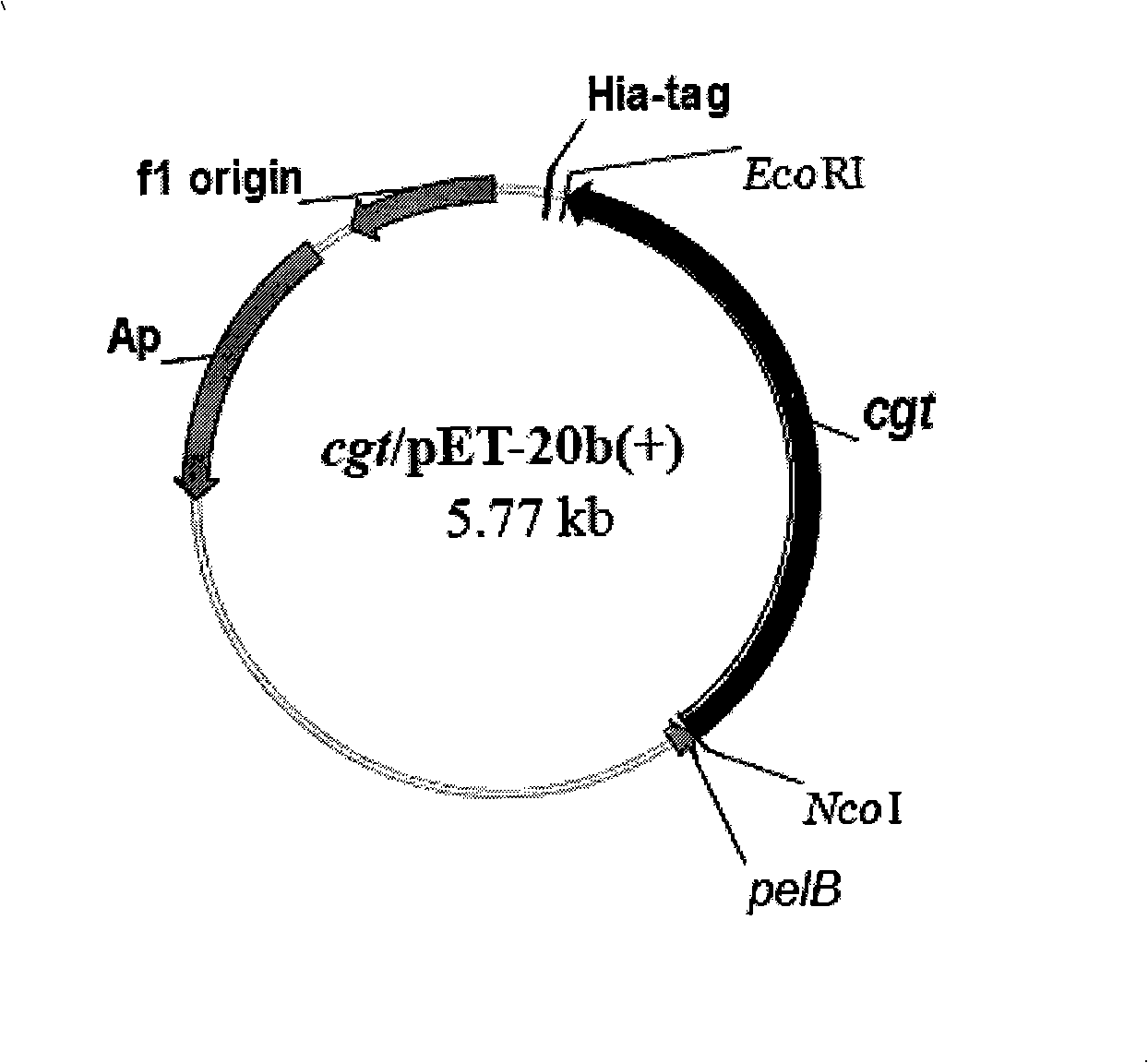

[0048] This example illustrates the cloning procedure for the gene encoding α-CGTase.

[0049] Using the total DNA of P.macerans JFB05-01 as a template, the following nucleotide sequences were used as primers, and the restriction sites Nco I and EcoR I were underlined to amplify the cgt gene by PCR.

[0050] Primer 1: 5'-CCATATgT CCATgg ATTCACCCgATACgAgC-3'

[0051] Primer 2: 5'-CTCgAgAg AATTC ggATTTTgCCAgTCCAC-3'

[0052] The PCR reaction was carried out in a 50 μL system: 10 μL of 5×PCR buffer, 4 μL of 2.5 mmol / L dNTPs, 1 μL of 10 μmol / L upstream and downstream primers, 1 μL of template DNA, 0.5 μL of Taq enzyme, and double distilled water to make the total system 50 μL;

[0053] The reaction conditions were 4 minutes of denaturation at 94°C, followed by 1 minute of denaturation at 94°C, 1 minute of annealing at 55°C, and 2 minutes of extension at 72°C for a total of 35 cycles, followed by 10 minutes of extension at 72°C. A PCR fragment of about 2100bp was amplified and...

Embodiment 3

[0055] This example illustrates the modification procedure of the cgt gene.

[0056] Since there is an Nco I restriction site inside the target gene, and the two ends of the gene are respectively Nco I and EcoR I sites, primers were designed to remove the mutation of the Nco I site to facilitate the cloning and expression in the next step. Use the pMD18-T simple vector connected to the cgt gene as a template for site-directed mutagenesis PCR, and design primers:

[0057] Primer 3: 5'-CAATgTgggTCCC ACA ATgggCCAgCC-3'

[0058] Primer 4: 5'-ggCTggCCCAT TgT gggACCCACATTg-3'

[0059] The PCR reaction was carried out in a 50 μL system, 5×PCR buffer 10 μL, 2.5 mmol / L dNTPs 4 μL, 10 μmol / L upstream and downstream primers 1 μL, template cgt / pMD18-T simple 1 μL, Taq enzyme 0.5 μL, add double distilled water to Total system 50μL;

[0060] The reaction conditions were denaturation at 94°C for 4 minutes, followed by denaturation at 94°C for 1 minute, annealing at 55°C for 1 minute, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com