Preparation of uniform nano-porous SiO2 low dielectric film

A nanoporous, low-dielectric technology, applied in the field of preparation of uniform nanoporous SiO2 low-dielectric films, can solve the problems of pore structure and distribution uniformity, unfavorable control of repeatability, uniform mixing of polymer and glass materials, etc. Achieve the effect of increasing porosity and increasing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

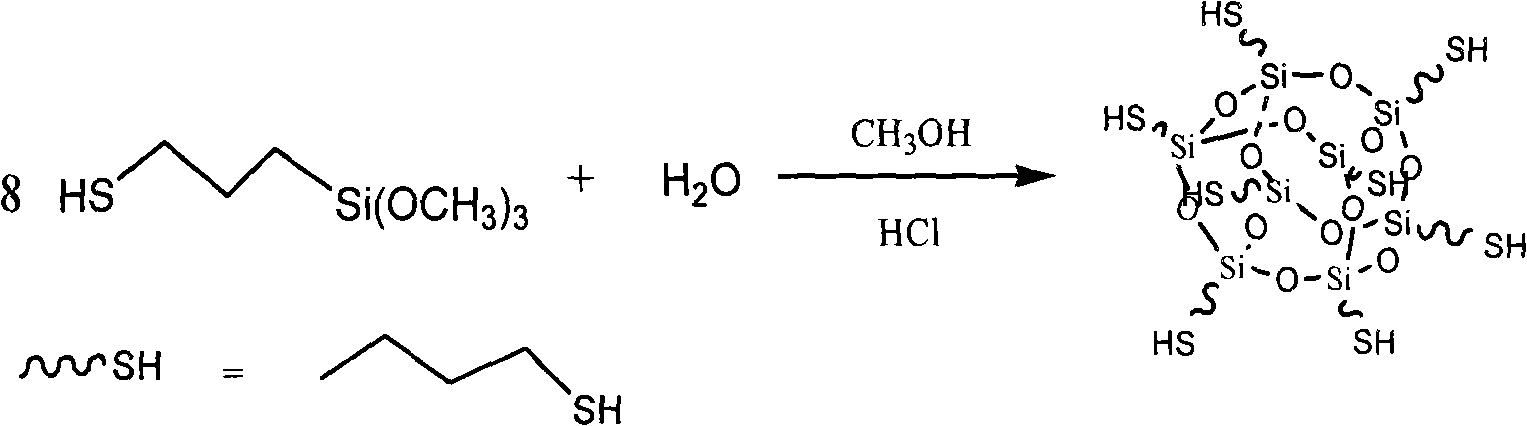

[0031] Synthesis of mercapto POSS: 196.30g (1.0mol) of γ-mercaptopropyltrimethoxysilane, 800mL of methanol, 55mL of distilled water and an appropriate amount of concentrated hydrochloric acid are used to adjust the pH value to 3.0, and then added to the In a 1500mL three-neck flask, under the protection of nitrogen, the reaction was carried out at a constant temperature of 60°C for 48h. Then stop heating and cool to room temperature, filter the product precipitated by the reaction, and wash the product with cyclohexane.

[0032]

[0033] Synthesis of diene monomer: Take a 1000mL flask, add 20.00g (0.144mol) p-hydroxybenzoic acid, then pour 300mL ethanol and 200mL water. Also known as 10g NaOH and 2g KI, dissolved in 100mL H 2 In O, add NaOH, KI solution to the ethanol-water solution drop by drop, after about 1~2h, add 13mL (0.153mol, excess) bromopropene, and reflux at 65~70°C for 70h. Stop the reaction, add 30mL of concentrated hydrochloric acid to acidify, rotary evapor...

Embodiment 2

[0040] Add 3g sodium lauryl sulfate, 1500mL petroleum ether, 80mL concentrated hydrochloric acid and 80g anhydrous FeCl to a 3000mL three-necked flask 3 , stirred for 30min. Another 80mL HSiCl 3 Dissolve in 800mL petroleum ether, under constant stirring, use constant pressure funnel to dissolve HSiCl 3 The solution was added dropwise into the three-necked flask, and the dripping was completed in about 8 hours. After the dropwise addition was completed, the stirring was continued for 30 min. Let stand, separate layers, pour out the upper yellow petroleum ether layer, add Na 2 CO 3 Neutralize and add anhydrous CaCl 2 Dry, filter, and concentrate to about 150 mL. Cool, crystallize, filter and collect the crystals. Washed 3 times with petroleum ether to obtain a white powder product. Recrystallized with cyclohexane to obtain white needle-like crystals, namely T 8 h 8 . The response is as follows:

[0041]

[0042] The synthesis and numbering of diene monomers are th...

Embodiment 3

[0047]Synthesis of vinyl POSS: 190.31g (1.0mol) of vinyltriethoxysilane, 500mL of ethanol, 52mL of distilled water and an appropriate amount of concentrated hydrochloric acid are used to adjust the pH value to 3.0, and they are added to a tank equipped with a stirrer, a thermometer and a reflux condenser. In a 1500mL three-neck flask, under the protection of nitrogen, the reaction was carried out at a constant temperature of 60°C for 48h. Then stop heating and cool to room temperature, filter the product precipitated by the reaction, and wash the product with cyclohexane.

[0048]

[0049] Synthesis of thiol monomer: 9.21 g (0.10 mol) of thioglycolic acid and 0.05 mol of diamine monomer were dissolved in 60 mL of benzene solvent, placed in a 150 mL round-bottomed flask, and heated to reflux at 110°C for 10 h. A solid product was obtained, which was purified by recrystallization from ethanol. Product number: M 1 ~ M 3 , the synthesis steps are as follows:

[0050]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com