Functional urea and preparation thereof

A urea and functional technology, applied in the field of functional urea and its preparation, can solve the problems of low utilization rate, high loss, fast volatilization, etc., and achieve the effects of improving fertilizer utilization rate, improving soil structure, and promoting nutrient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

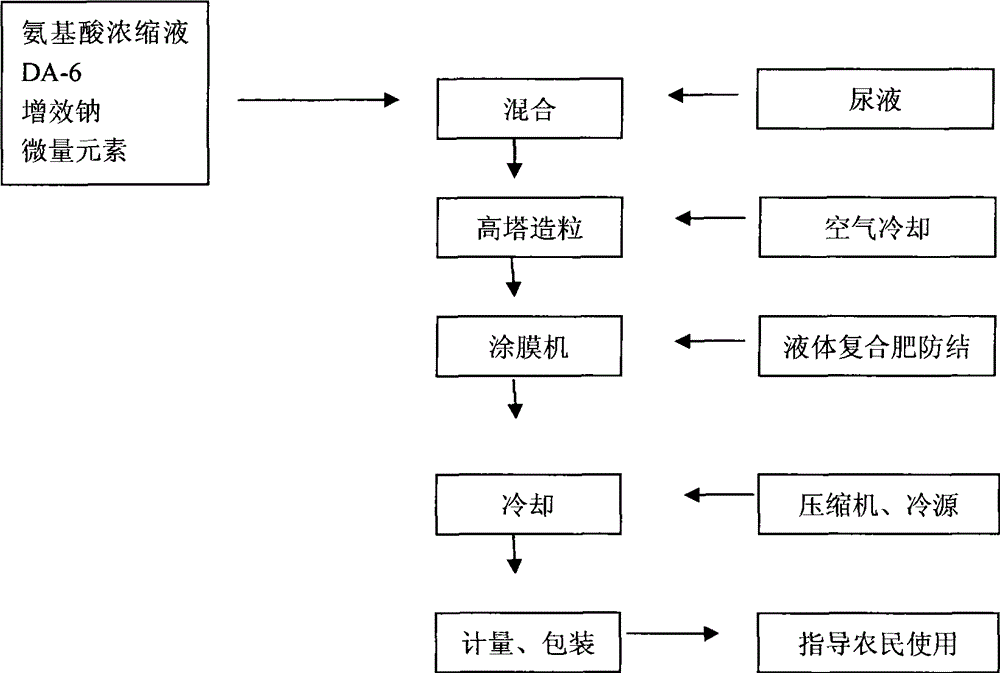

Embodiment 1

[0053] The component weight formula of the present embodiment is:

[0054] N46.4 Urine 1000 Mixture of trace elements 3

[0055] 98% amino acid concentrate 2 Liquid compound fertilizer anti-caking agent 1~2

[0056] 98% plant growth regulator (DA-6) 0.5

[0057] 98% bioaccelerator (sodium synergist) 0.5

[0058] The weight ratio of the trace element mixture is as follows:

[0059] Zinc sulfate 1.2 Ammonium molybdate 0.3

[0060] Copper sulfate 0.6 Boric acid 0.9

[0061] Preparation:

[0062] In the second-stage evaporator section of the urea production process in the chemical plant, a mixing tank, a flow meter, and a booster pump are added to add the above-mentioned amino acid concentrate, (DA-6), (sodium synergist) , Trace elements are measured and heated to 95°C by the mixing tank, and then the flow meter is used to control the flow rate with a computer setting program in proportion, and then the booster pump injects the above molten liquid into the second-stage evapo...

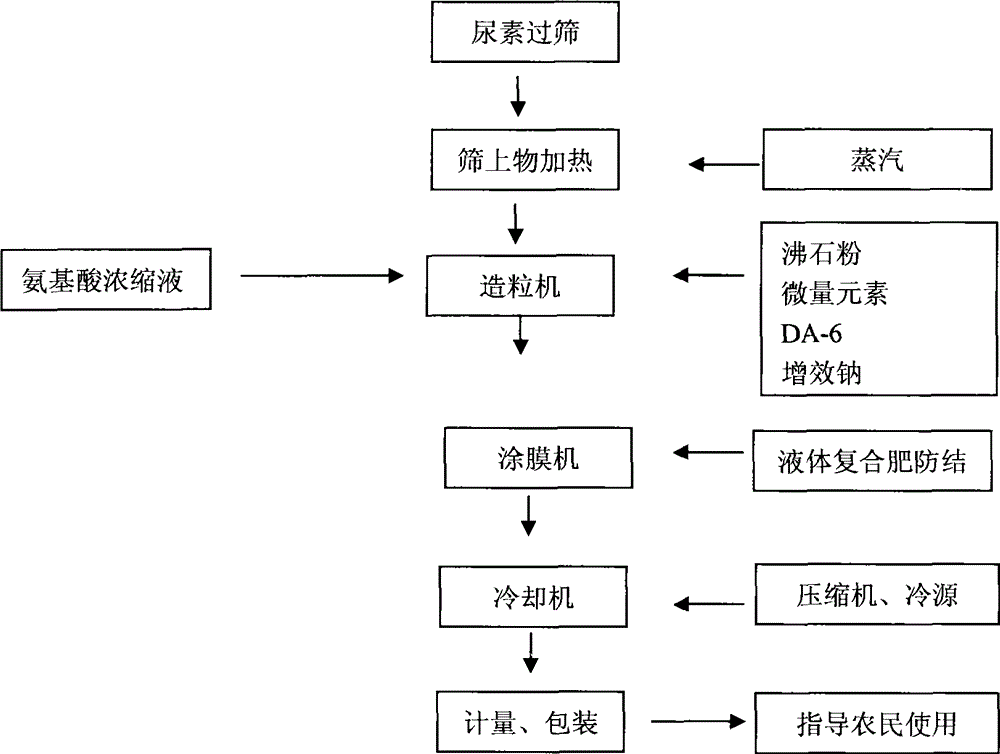

Embodiment 2

[0064] The component weight formula of the present embodiment is:

[0065] N46.4 Urea 860 Mixture of trace elements 30

[0066] 98% Amino Acid Concentrate 10 Zeolite Powder 100

[0067] 98% plant growth regulator (DA-6) 0.3 Liquid compound fertilizer anti-caking agent 1~2

[0068] 98% bioaccelerator (sodium synergist) 0.3

[0069] The weight ratio of the trace element mixture is:

[0070] Zinc sulfate 15 Ammonium molybdate 3

[0071] Copper sulfate 6 Boric acid 6

[0072] Preparation:

[0073]Sieve the urea granules, take the sieve (irregular small particles, powder for other purposes), heat to 85-90°C with steam, heat the amino acid concentrate to 90°C in a mixing tank, and use a flowmeter Under the control of the computer, the special pressure pump is pressurized and sprayed on the heated urea granules, and the urea is continuously turned by the force of the drum granulator to make it produce a weak acid reaction. The surface of the urea granules becomes sticky, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com