Preparing method for reinforcing graphic luminous compound film by nano crystal

A patterned and nanocrystalline technology, applied in the field of optoelectronic information, can solve problems such as difficult fluorescent pattern output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

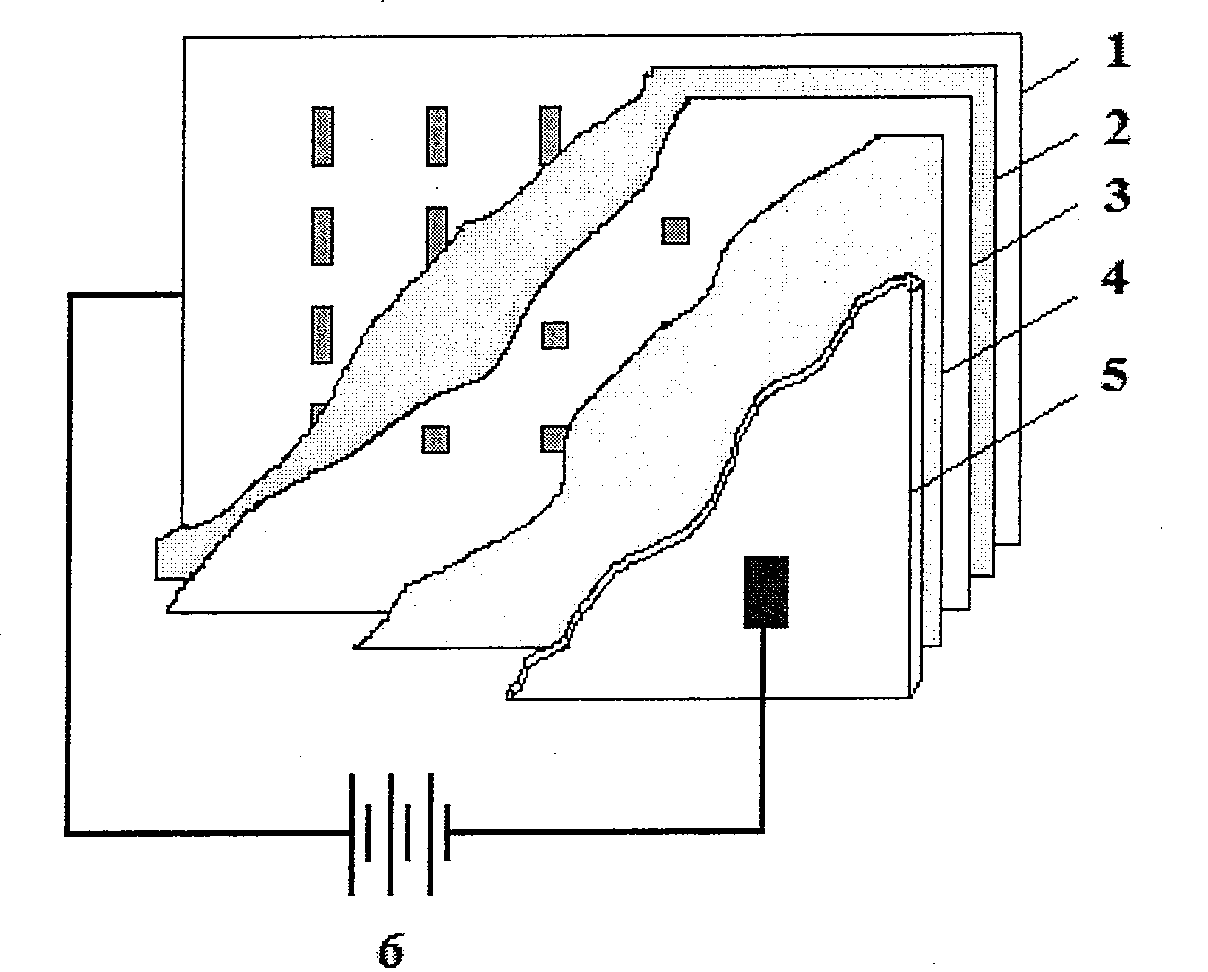

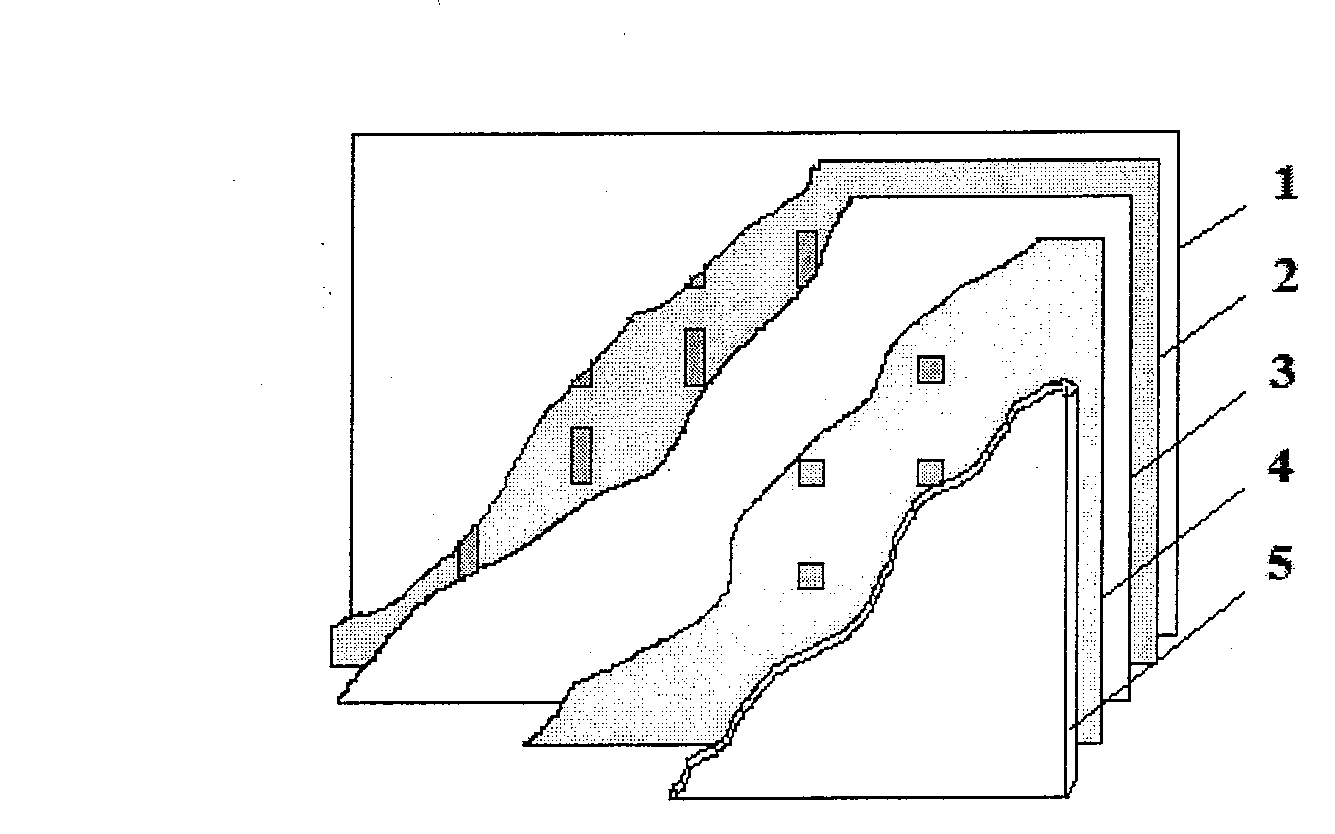

Method used

Image

Examples

Embodiment 1

[0020] Using 1,2-propanediol as solvent, add 0.8M 1,2-propanediol tellurium, 0.2M niobium oxalate, 0.2M barium chloride, 0.01M europium nitrate successively, age at 60°C to form a sol, and use a homogenizer to coat on On a silicon single crystal substrate, it is heated to 130°C to polymerize to form a tellurate gel film, and the film is heat-treated at 400°C to obtain a europium-containing tellurite system glass film. Using absolute ethanol as the solvent, add 1M ethyl orthosilicate, 0.05M chloroauric acid, and add 3M water for hydrolysis and polymerization to form a sol, and use the inkjet printing method to form graphics on the surface of the glass film containing europium tellurate system The film layer is formed by aging and heat treatment at 250°C to form a gold-containing graphic film layer. With the gold-containing graphic film layer as the anode, and the uncoated side surface of the silicon single crystal substrate as the cathode, apply a DC electric field with a stren...

Embodiment 2

[0022] Using absolute ethanol as solvent, add 0.8M ethyl orthosilicate, 0.2M tellurium chloride, 0.2M sodium ethoxide, 0.01M samarium nitrate successively, and add 3M water to carry out hydrolysis and polymerization at 60°C to form a sol. A glue machine coats the prepared sol on an optical glass substrate and ages it to form a gel film, and heat-treats the gel film at 450°C to obtain a samarium-containing silicon tellurate system glass film. The silver halide photographic emulsion is coated on the glass film containing samarium silicon tellurate system, the metal silver graphic film layer is formed by exposure method, and the unimaged part is washed away. With the metal silver graphic film layer as the anode, and the uncoated side surface of the optical glass substrate as the cathode, apply a DC electric field with a strength of 200V / mm, and place it in a heat treatment furnace at a temperature of 300°C for 60 minutes, then remove the electric field and reheat at 450 ℃ for 120...

Embodiment 3

[0024] Using absolute ethanol as solvent, add 0.7M ethyl orthosilicate, 0.2M butyl titanate, 0.1M zirconium isopropoxide, 0.2M potassium nitrate, 0.01M erbium nitrate, and add 3M water at 60°C Hydrolyze and polymerize to form a sol, and use a homogenizer to coat the prepared sol on an optical glass substrate and age it to form a gel film. The gel film is heat-treated at 500°C to obtain the first layer of erbium-containing silicon-titanium-zirconium system glass film . Using absolute ethanol as a solvent, add 1M tetraethyl orthosilicate, 0.05M silver nitrate, and 3M water for hydrolysis and polymerization to form a sol, and use the screen printing method to coat the sol on the glass film of the erbium-containing silicon-titanium-zirconium system The surface is aged to form a silver-containing gel film pattern, and the first silver-containing pattern film layer is formed by heat treatment at 250°C. Using 1,2-propanediol as a solvent, add 0.6M 1,2-propanediol tellurium, 0.2M nio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com