Self-supporting lithium ion battery gel polymer electrolyte and preparation method thereof

A lithium-ion battery, gel polymer technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of unsatisfactory electrochemical stability window, unsatisfactory ionic conductivity, and narrow applicable temperature range. Excellent liquid absorption and liquid holding capacity, good electrochemical stability, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Polymer electrolyte without added nanoparticles:

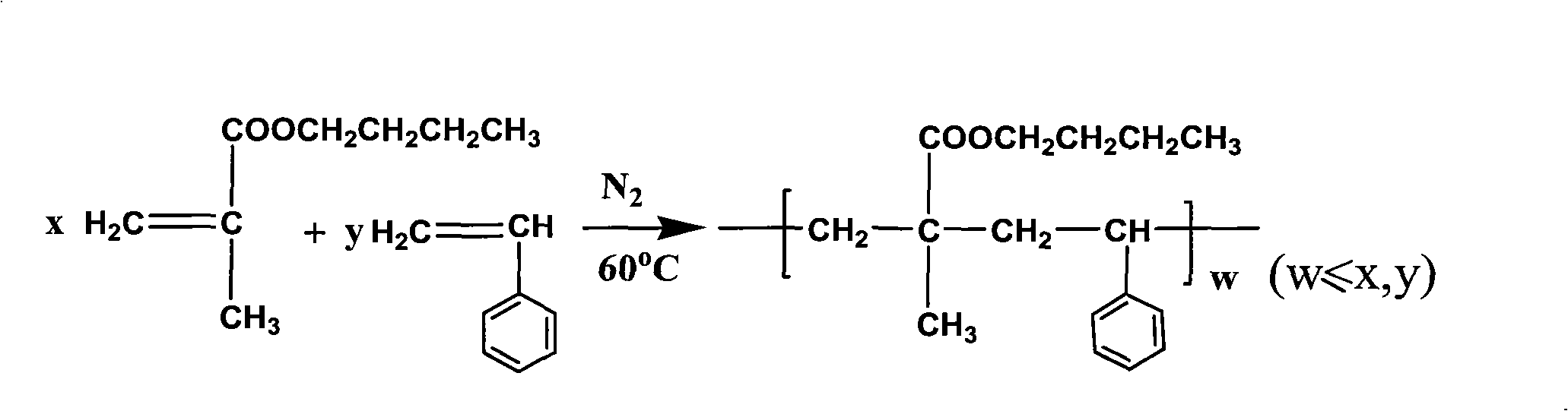

[0032] (1) The monomers n-butyl methacrylate (BMA) and styrene (St) used in the polymerization are both analytically pure. Before the experiment, the monomers are distilled to remove the polymerization inhibitor hydroquinone. The following other examples all performed this treatment on the monomer before the reaction.

[0033] In N 2 Under the protection of the atmosphere, add 1.5 parts by mass of emulsifier sodium lauryl sulfate into 64.7 parts by mass of deionized water to dissolve, stir for 0.5 hours and add 33.5 parts by mass of monomer BMA and St (wherein the mass ratio of BMA and St is 1:1), while raising the temperature to 58°C. After reacting for 0.5 hours, add 0.3 parts of sodium persulfate (dissolved in 40ml of deionized water) with a constant pressure funnel, and control the titration speed, which is preferably 1~2s / drop. At the same time, adjust the speed of the stirrer. It is 500r / min. After 9 hours of reaction...

Embodiment 2

[0038]Polymer electrolyte without added nanoparticles:

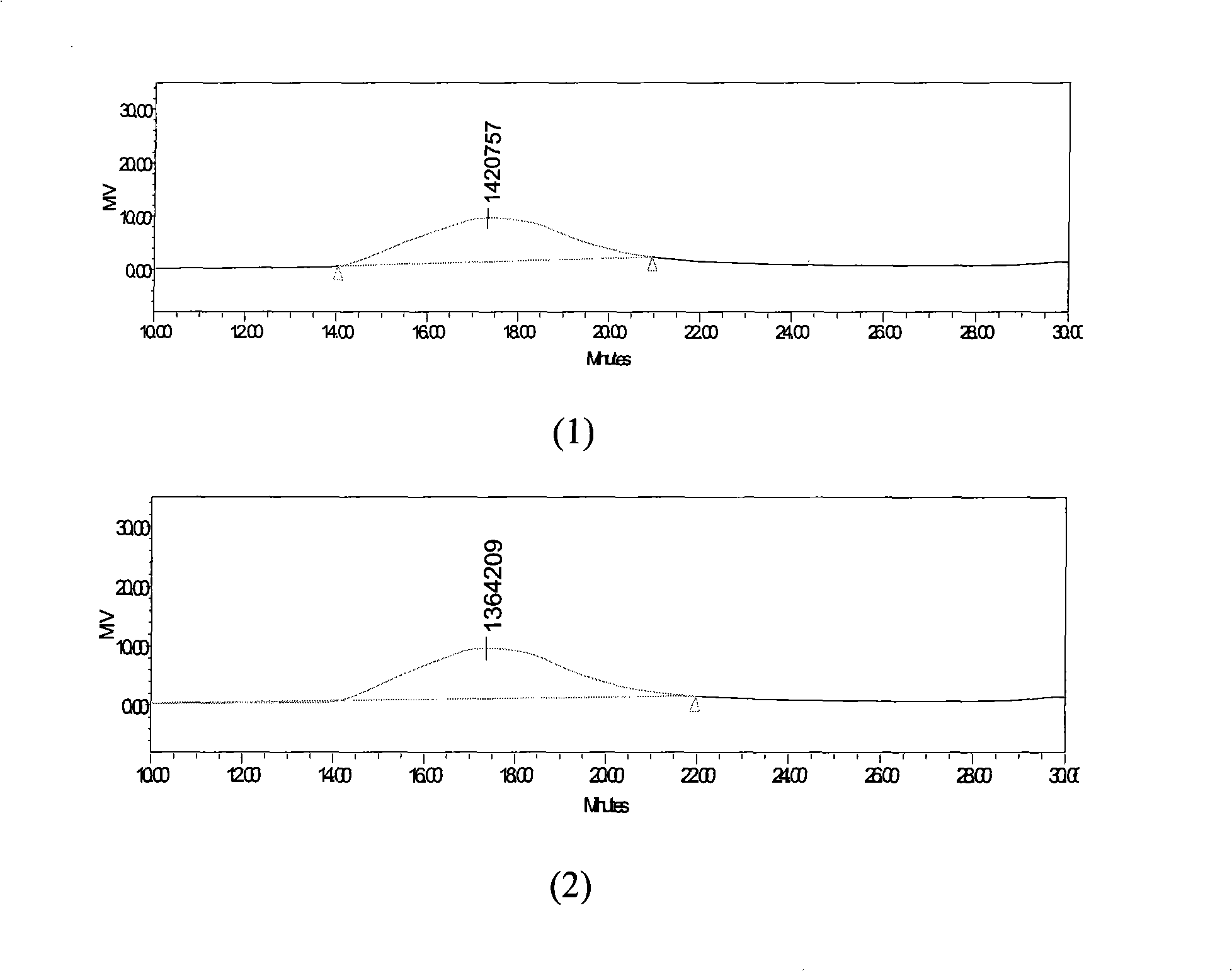

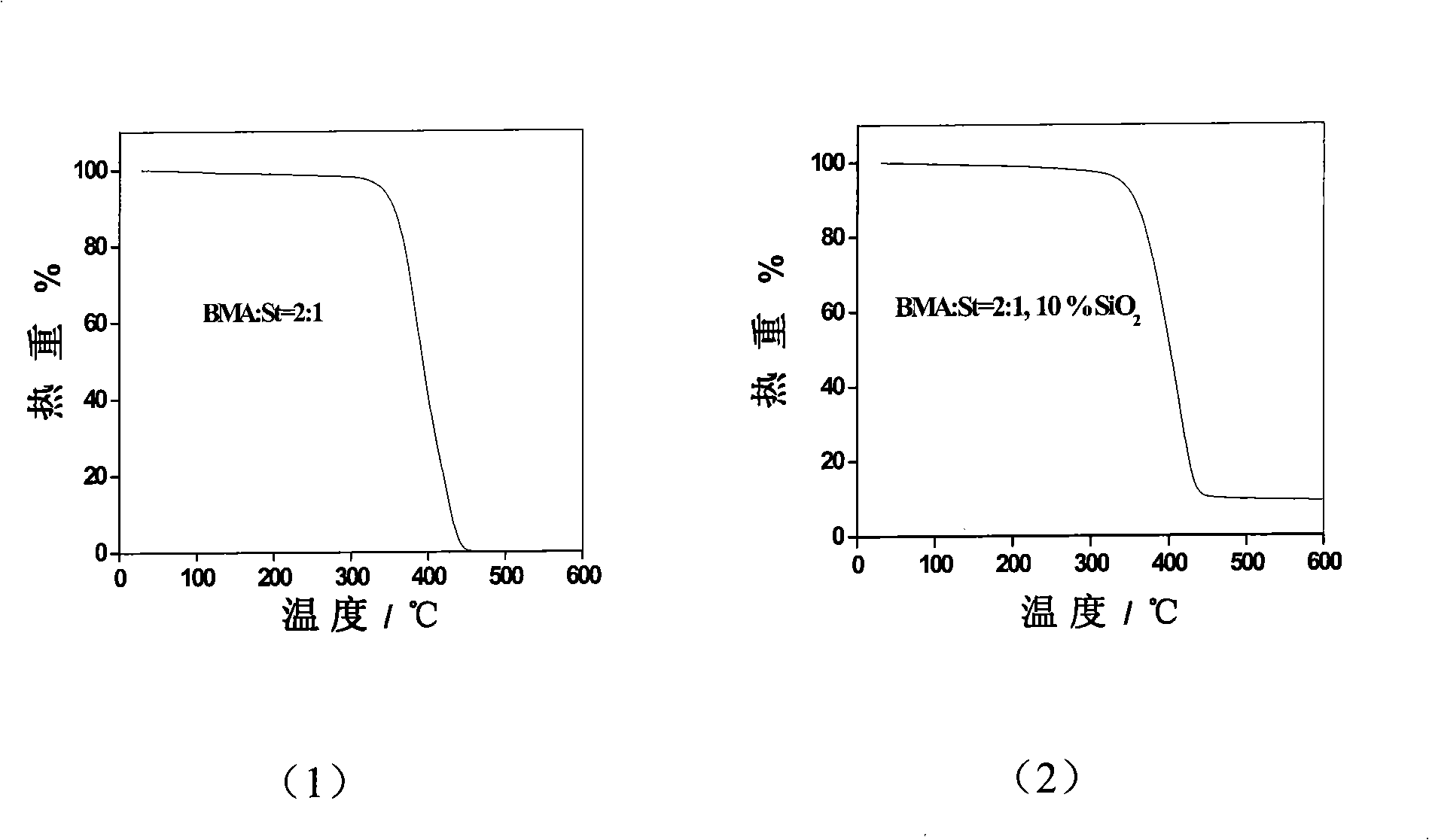

[0039] (1) Under the protection of Ar atmosphere, add 1.3 parts by mass of emulsifier potassium lauryl sulfate to 63 parts by mass of deionized water to dissolve, and after stirring for 0.5 hours, add 35.3 parts by mass in sequence Parts of the monomers BMA and St (wherein the mass ratio of BMA and St is 2:1), while raising the temperature to 60°C. After 1 hour of reaction, use a constant pressure funnel to add 0.4 parts by mass of the initiator potassium persulfate (dissolved in 50ml of deionized water), and control the titration rate. It is advisable to use 1~2s / drop. The speed is set to 550r / min. After 7 hours of reaction, an egg white emulsion is obtained, and the egg white emulsion is poured into 1.5 times the above reaction volume, Al 2 (SO 4 ) 3 Stir and demulsify in a solution of 4 parts by mass, then wash 5 times with deionized water at 60°C and 10 times with deionized water at room temperature to obtain a white pol...

Embodiment 3

[0043] (1) In N 2 Under atmosphere protection, add 2 parts by mass of emulsifier sodium lauryl sulfate to 64.7 parts by mass of deionized water to dissolve, stir for 0.5 hours and add 32 parts by mass of monomer BMA and St (wherein the mass ratio of BMA and St is 1:1), while raising the temperature to 58°C. After reacting for 0.5 hours, add 0.3 parts of sodium persulfate (dissolved in 40ml of deionized water) with a constant pressure funnel, and control the titration speed, which is preferably 1~2s / drop. At the same time, adjust the speed of the stirrer. It is 500r / min. After 9 hours of reaction, an egg white emulsion is obtained, and the egg white emulsion is poured into 1 times the above reaction volume, Al 2 (SO 4 ) 3 Stir and demulsify the solution with 3 parts by mass, then wash 4 times with deionized water at a temperature of 58°C and 8 times with deionized water at room temperature to obtain a white polymer; place the obtained white polymer in a vacuum drying oven Dry at 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com