Preparation of precise resistance/strain sensitive conductive silicon rubber

A technology of precision resistance and conductive silicon, which is applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring devices, instruments, etc., can solve the problems of inability to achieve repeatability, achieve good environmental compatibility, good conductivity and ductility, and cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 3 grams of ruthenium chloride hydrate in 3 liters of analytically pure 1,2-propanediol, heat to 60°C, stir vigorously to dissolve completely, then slowly heat to 150°C and keep for 30 minutes, the solution turns from reddish brown to black, naturally Cool down to room temperature and let it stand for 24 hours. Most of the nanoparticles formed in the solution will settle to the bottom of the container. Remove most of the propylene glycol solution. Clear the solution, then add 100 milliliters of ethanol, repeat washing three times, and dry to obtain metal ruthenium powder with an average particle size of 2 nanometers and an average aggregate size of 200 nanometers. The above powder was heated to 600°C in the air, and kept warm for 0.5 hours to obtain fully oxidized rutile phase ruthenium oxide powder, and the powder was rolled and dispersed to obtain a single ruthenium oxide particle with an average size of 20 nanometers and an average aggregate size of 80 nm rut...

Embodiment 2

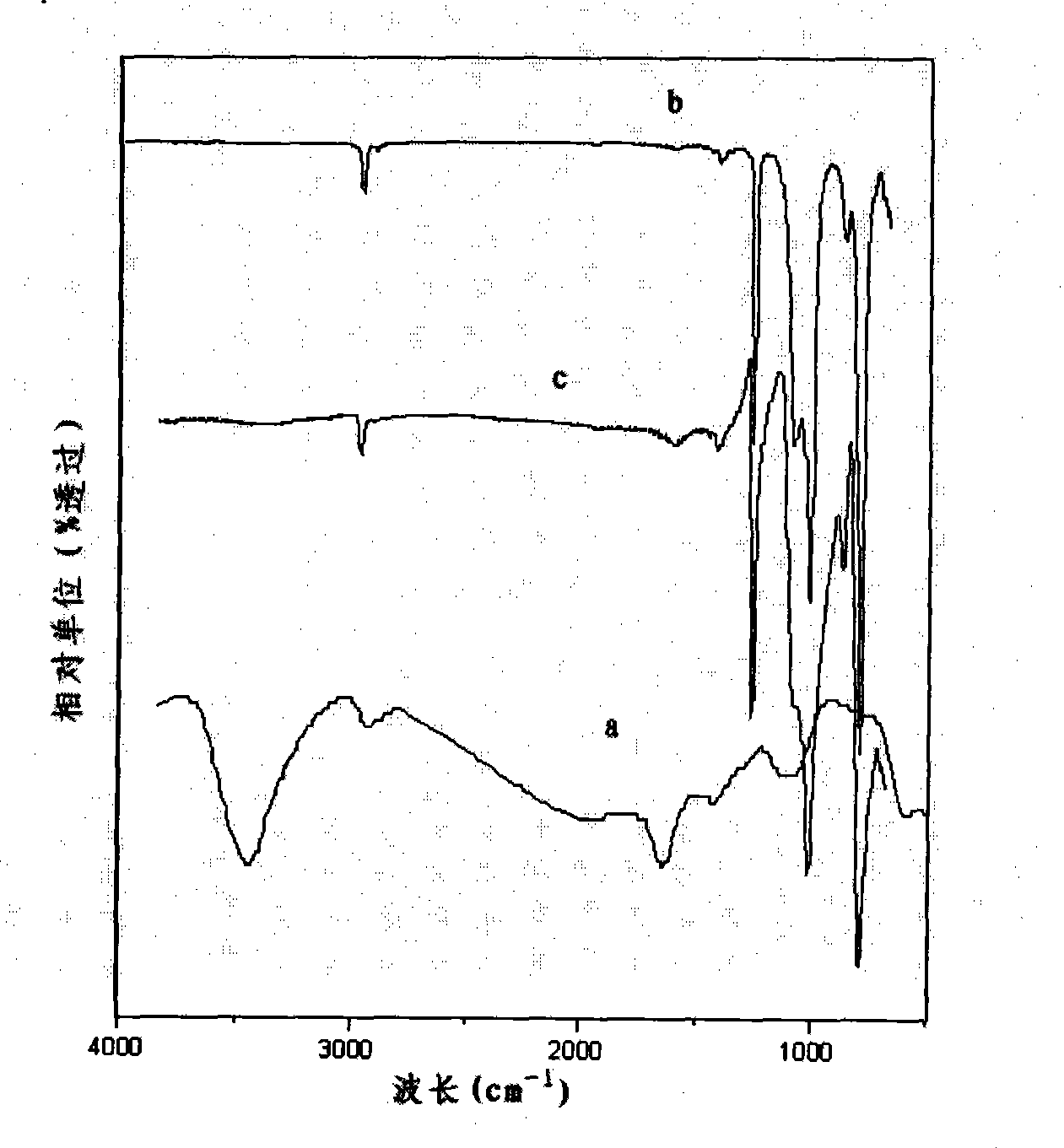

[0030] Ultrasonic disperse the above ruthenium oxide powder in ultrapure water and ammonia water with a volume ratio of 1:5, keep it for 20 minutes, centrifuge at 15000g, remove the supernatant solution, disperse the precipitated powder with methanol, precipitate, and repeat washing three times. After drying, the hydrophilic surface is rich in hydroxyl nanometer ruthenium oxide powder, and its infrared absorption spectrum is as follows: image 3 , Figure 4 shown.

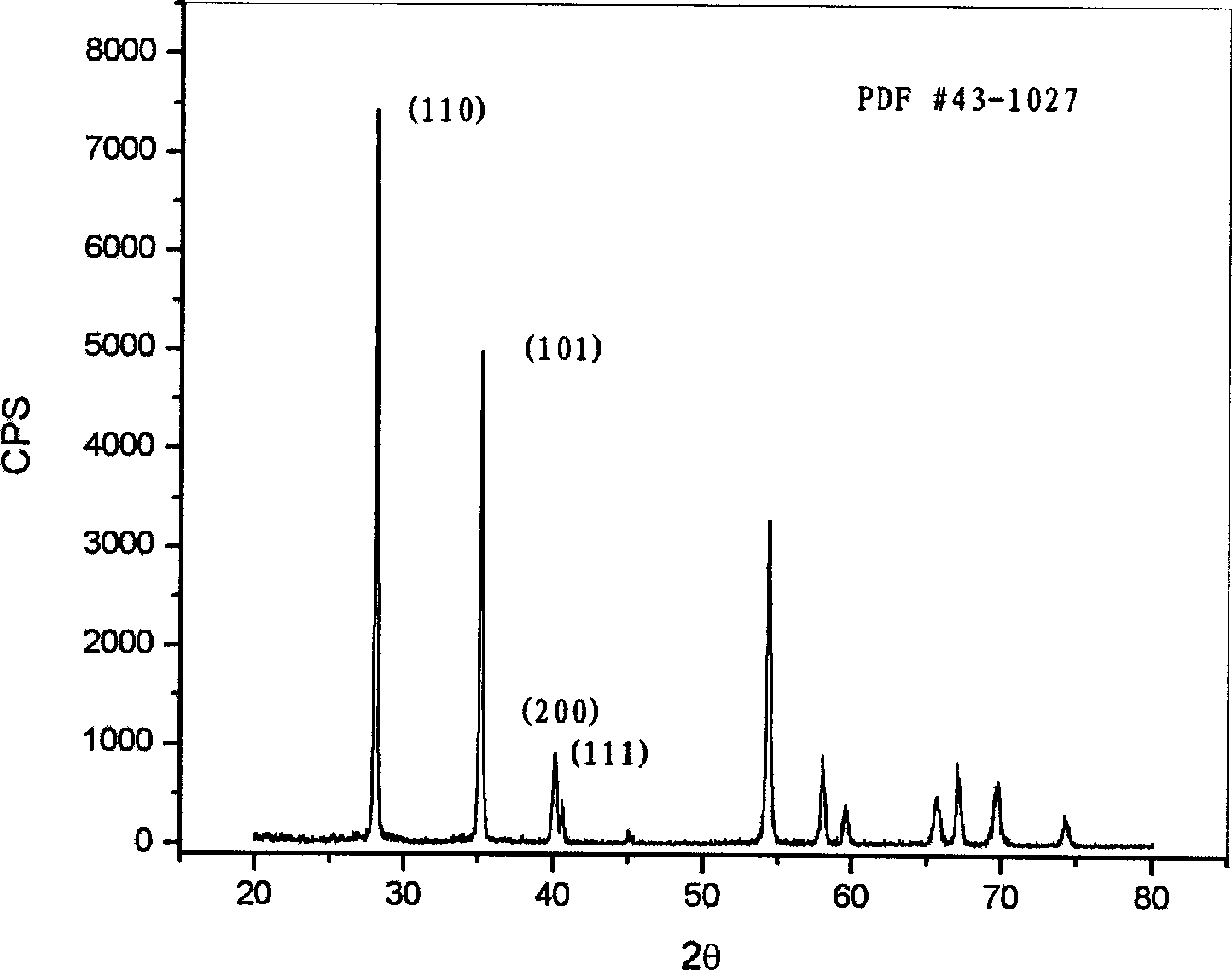

[0031] Disperse 0.3 g of the above powder in 10 ml of ethanol ultrapure aqueous solution with a volume ratio of 1:1, then add 0.5 ml of triethoxyvinylsilane, ultrasonicate for 3 minutes, let stand for 3 hours, remove the supernatant, and wash with ethanol Sedimentation, washing three times, drying to obtain surface-modified vinyl ruthenium oxide powder, its infrared absorption spectrum is as follows: figure 2 As shown, the transmission electron micrograph and X-ray diffraction spectrum of ruthenium oxide powder ...

Embodiment 3

[0033] Take 200 mg of methyl vinyl polysiloxane raw rubber material with a vinyl molar ratio of 1% and a molecular weight of 500 kDa, add 472 mg of the above-mentioned surface-modified ruthenium oxide powder, and add 6 mg of surface-modified gas-phase powder with a particle size of 20 nanometers. White carbon black, add 3 ml of n-hexane, after the silica gel is dissolved, grind, ultrasonically disperse, dry at 60°C for 2 hours, then add 13 mg of 2,5-dimethyl-2,5-di-tert-butyl peroxide Hexane, after repeated grinding and mixing, let it stand for 30 minutes, fill it into the mold, the mold pressure is not less than 10Mpa, keep it warm at 175°C for 20 minutes, cool down and demould, and obtain a conductive silicone rubber material with a volume ratio of the conductive phase of 25%. The resistance-pressure relationship of the material under 12 consecutive repetitions of compression deformation is as follows: Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Bulk resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com