Three-dimensional large aperture tissue engineering scaffold based on nano-fibers and application thereof

A tissue engineering scaffold and nanofiber technology, applied in medical science, prosthesis, etc., can solve the problems of affecting tissue regeneration, easy collapse, poor excretion, etc., to achieve good mechanical properties, reduce degradation products, and reduce the effect of the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

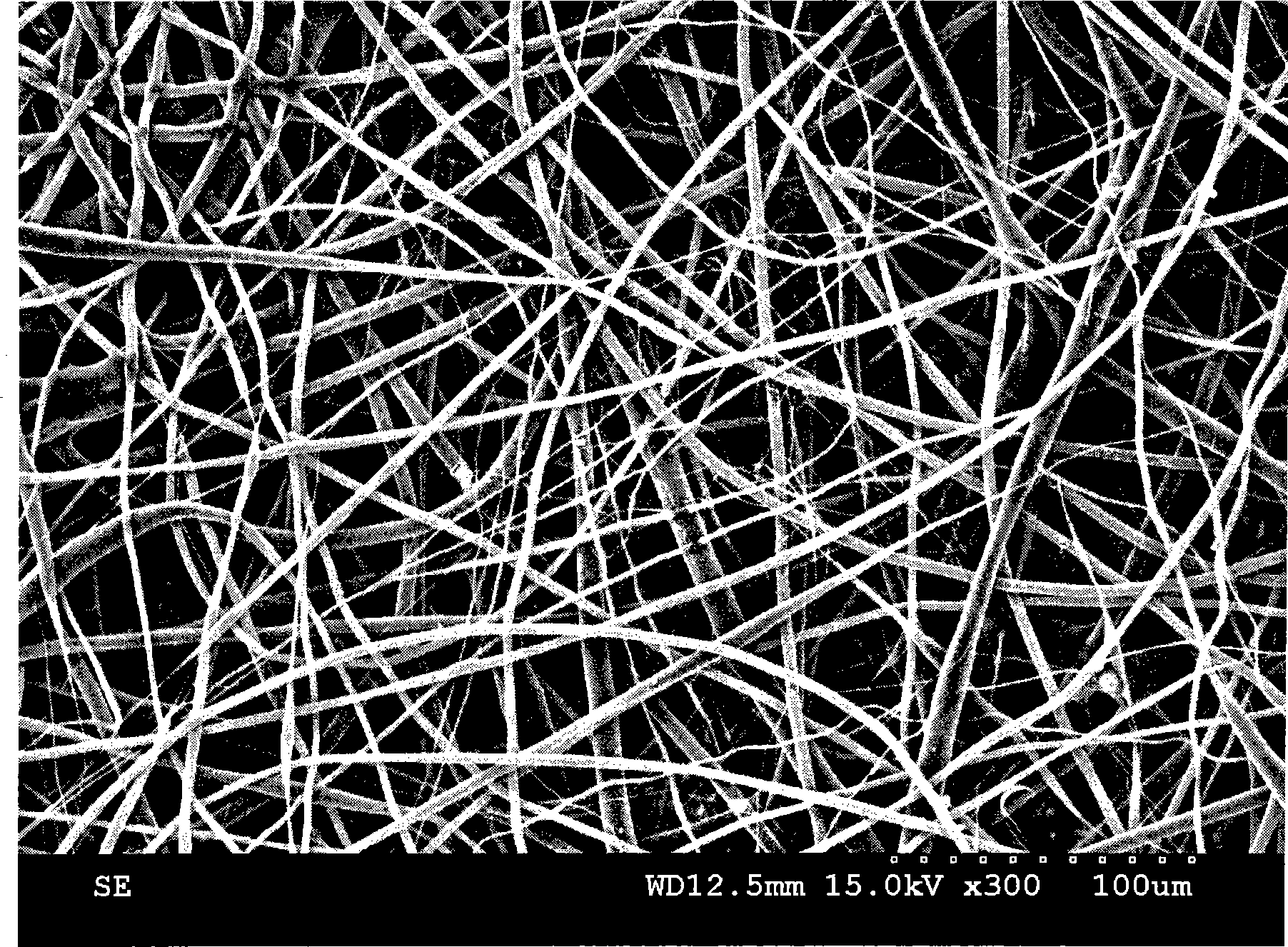

[0028] First prepare a PLLA solution with a concentration (10 mg / ml), and the solvent is chloroform / ethanol (v / v=3:1). The nanofiber membrane is prepared by electrospinning (control flow rate is 0.5ml / h~1.0ml / h, voltage is 14KV~16KV) technology (see the electron microscope photo figure 1 ), cut the prepared nanofiber membrane into thin strips with a width of 50-200 μm and a thickness of 50-200 μm to obtain micro-fibers. The micro-fibers are staggered and stacked to form a three-dimensional configuration. PCL nano-filaments are added and heated and melted at a temperature above 65 degrees for 1 minute. After cooling, a three-dimensional large-pore tissue engineering composite scaffold composed of nanofibers can be obtained (the resulting nanofiber layer has a pore size of 100-500 nm, and the micron fiber layer has a pore size of 50-200 μm). The bone marrow mesenchymal stem cells were planted on the fiber scaffold, and the cells were observed under the electron microscope after 7 d...

Embodiment 2

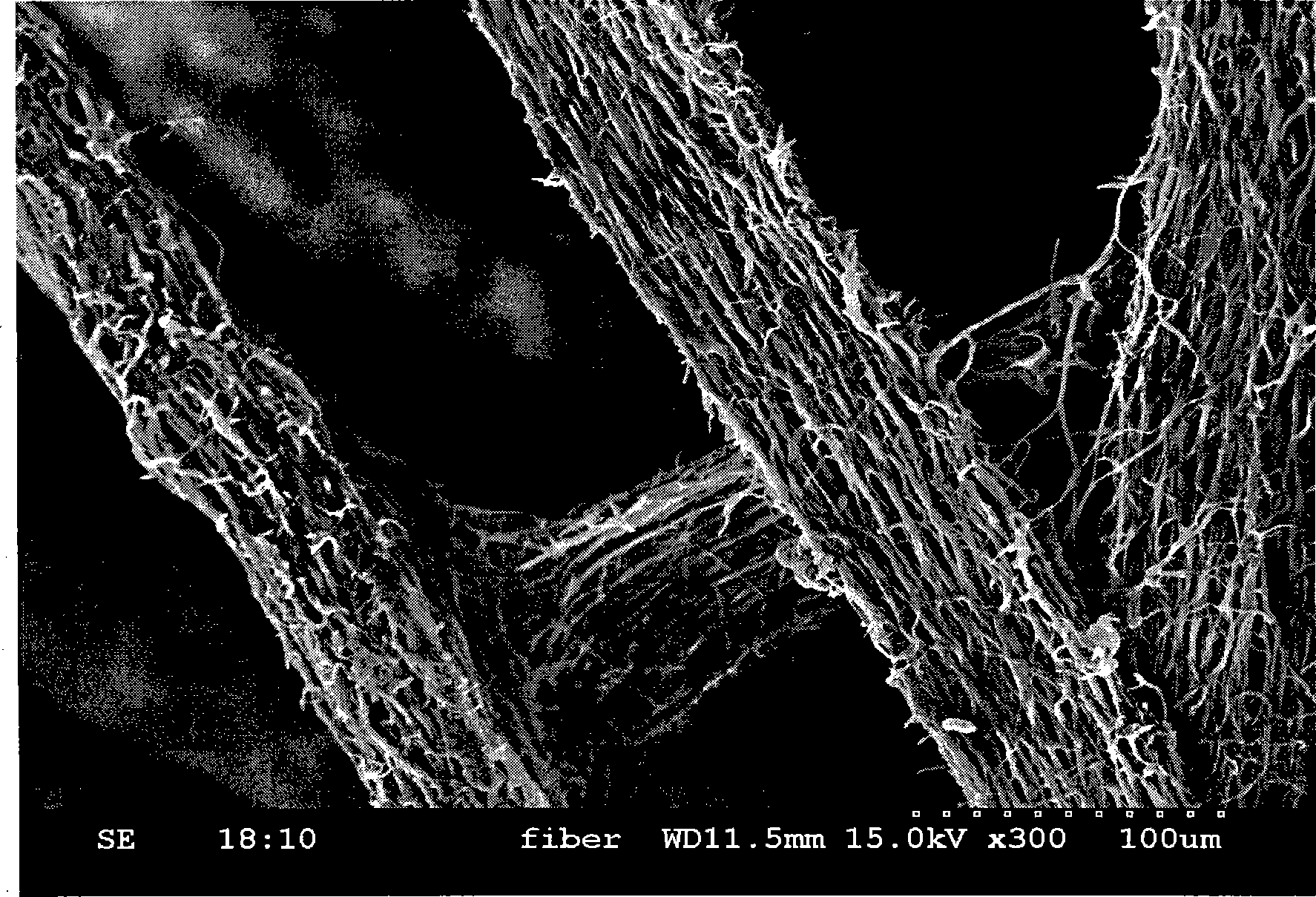

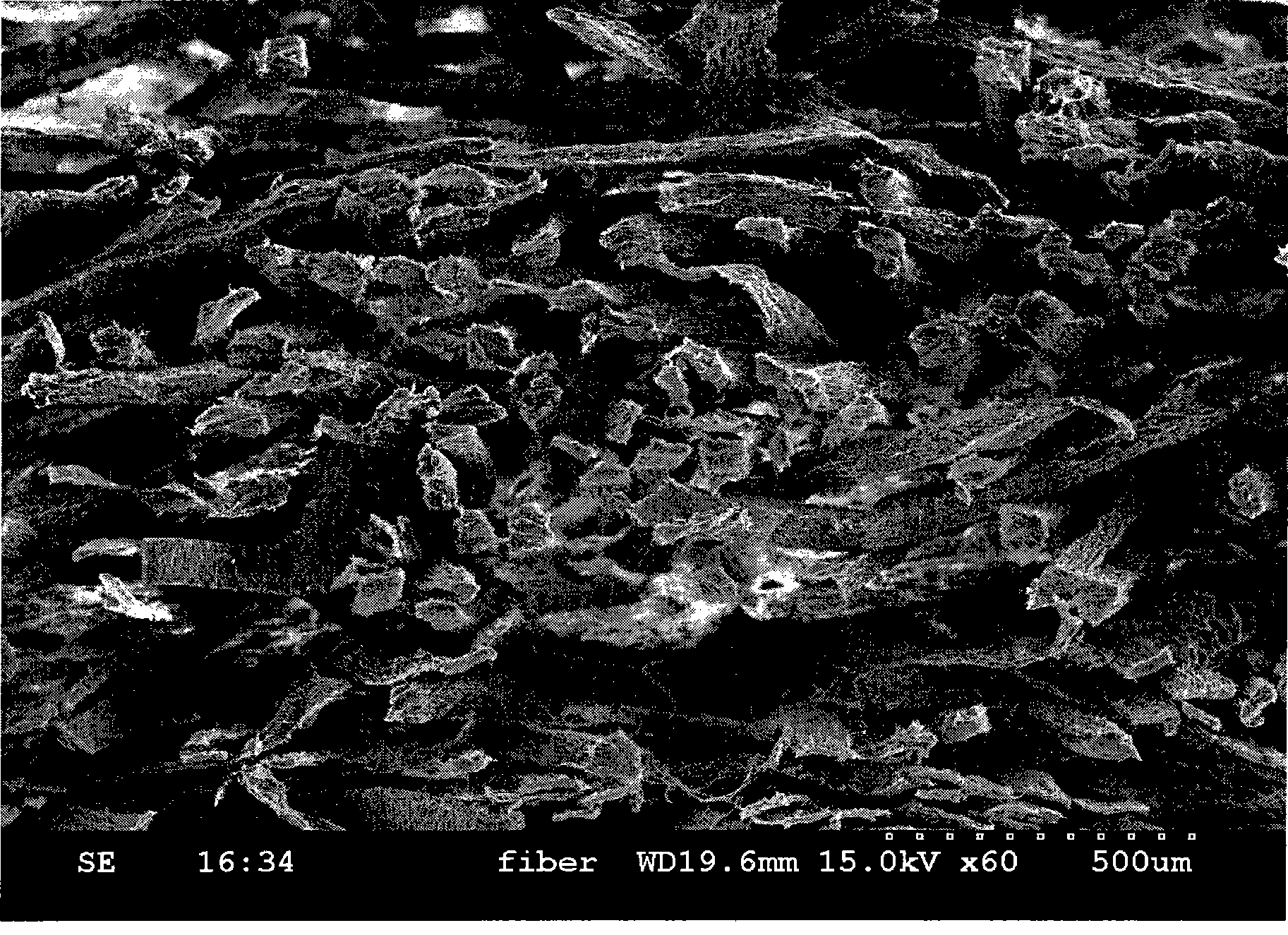

[0030]First prepare a PGA solution with a concentration (15 mg / mL), and the solvent is chloroform / ethanol (v / v=3:1). The nanofiber membrane is prepared by electrospinning (control flow rate is 1.5ml / h~2.0ml / h, voltage is 16KV~18.7KV) technology, and the film thickness is 200~500μm. The obtained nanofiber membrane is cut along a certain axial direction, and the cutting distance can be 200-500 μm to produce micron fibers with a primary structure. Then assemble according to the required block shape, soak in 3mg / ml collagen solution, lift up and filter dry for 1 minute, freeze at -70℃, freeze-dry it, and obtain nanofibers as the base layer, three-dimensional assembled by microfibers Micron pore size tissue engineering composite scaffold. (see figure 2 , image 3 ) (The diameter of the obtained nanofibers is 100-1000 nm, and the pore diameter of the scaffold is 100-500 μm).

Embodiment 3

[0032] First prepare a mixed solution of PLLA (10mg / mL) and TCP (5mg / ml), the solvent is chloroform / ethanol (v / v=3:1). Prepare nanofiber membranes by electrospinning (control flow rate is 0.5ml / h~1.0ml / h, voltage is 14KV~16KV) technology, and cut the prepared nanofiber membrane into thin strips with a width of 50~200μm and a thickness of 50~200μm , To obtain micro-fibers, the micro-fibers are staggered to form a three-dimensional configuration, (add PCL nanowires, heat and melt at 65 degrees or more for 3 minutes, after cooling, a three-dimensional large-pore tissue engineering composite scaffold composed of nanofibers can be obtained (the scaffold has a 50 ~200μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com