Method for preparing inkjet water-soluble ink containing noble metal nano particles

A gold nanoparticle and nanoparticle technology, which is applied in ink, printing, household utensils, etc., can solve the problems of complex preparation process, large error range, and obvious error, and achieve simple preparation method, high precision, and ink storage time lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

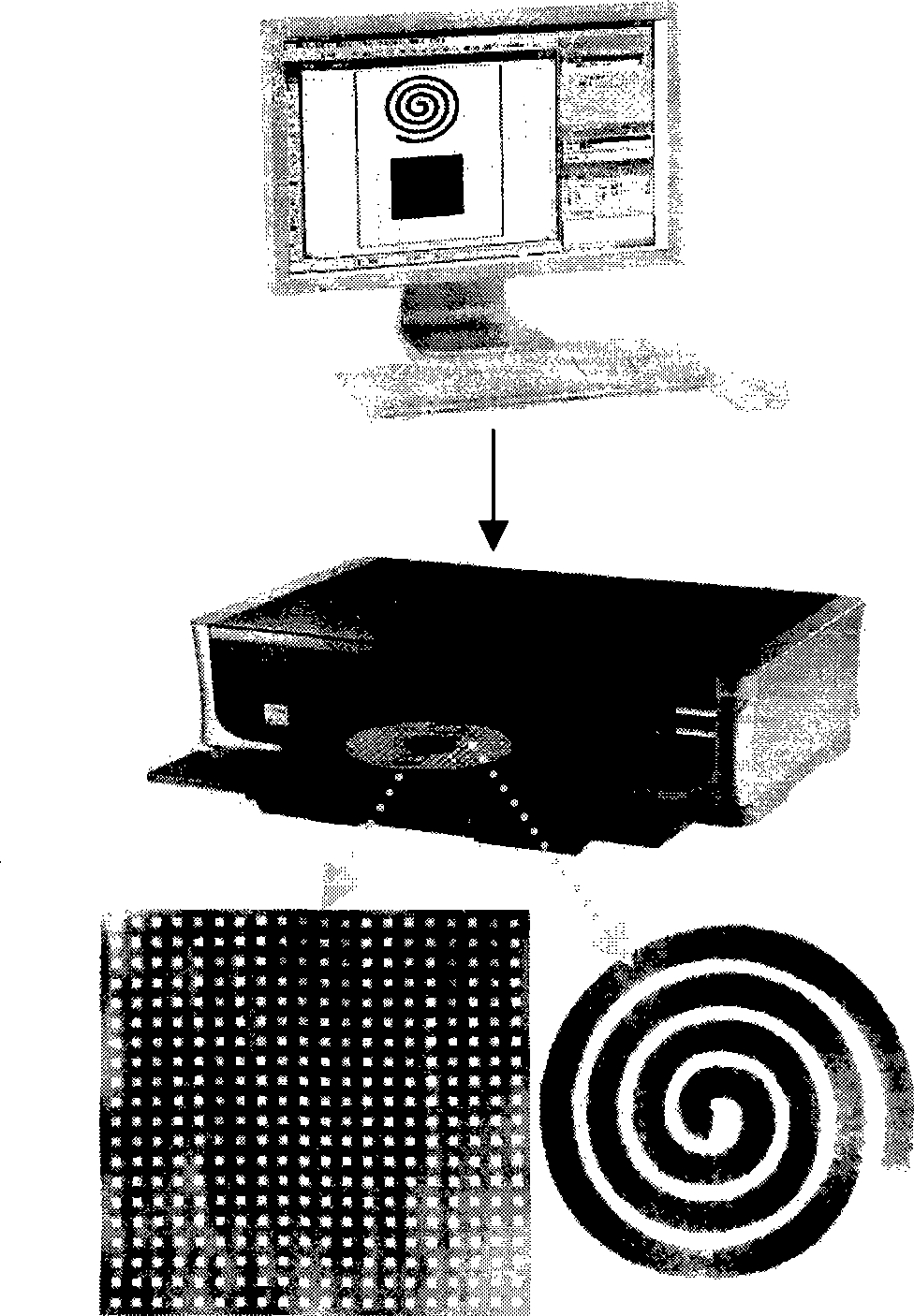

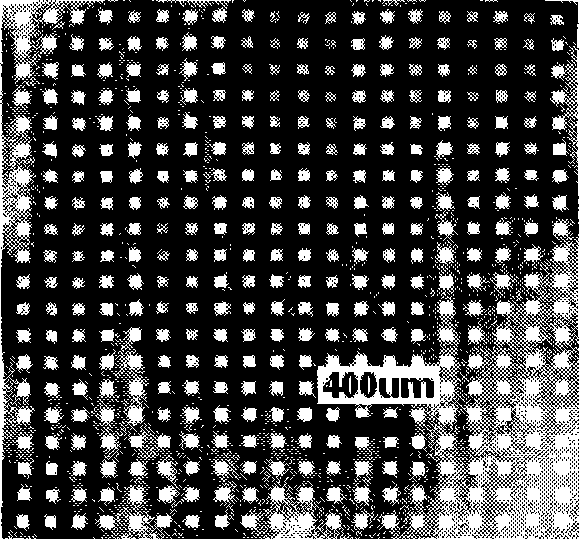

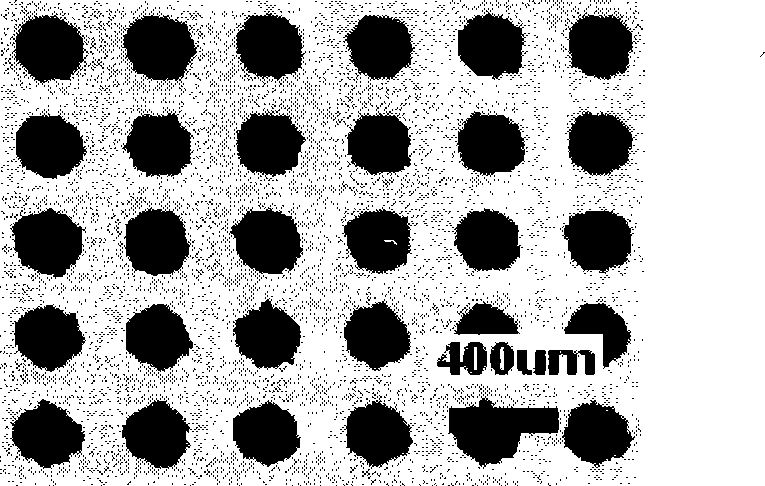

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Preparation of gold nanoparticle inkjet ink

[0048] Take 0.80 g of ethylene oxide and propylene oxide copolymer solid, add 0.6 mL of ammonia water, add 10 mL of secondary distilled water, and heat to dissolve completely. After standing for 24 hours, add 50 mL of the prepared water-soluble gold nanoparticle aqueous solution containing 0.02 g / mL with an average particle size of 8 nm, 0.40 g of N-methyl-2-pyrrolidone, and heat and ultrasonically disperse for 30 minutes. Concentrate at a constant temperature of 1 °C for 12 hours, add 3 mL of cyclohexane after cooling to room temperature, and ultrasonically disperse it with an ultrasonic cleaner for 5 to 10 minutes at room temperature. Continue ultrasonic heating and concentration at a constant temperature of 50±1 °C until the solution volume is about 10 mL, and measure the pH value. is 7, that is, the gold nanoparticle inkjet water-soluble ink is obtained. The physical properties of this ink at 25°C are as follo...

Embodiment 2

[0051] Example 2 Preparation of platinum nanoparticle inkjet ink

[0052] Take 0.80 g of the copolymer of maleic butene and styrene, 0.50 g of lithium hydroxide, and 10 mL of secondary distilled water, and heat to dissolve completely. After standing for 24 hours, 50 mL of the prepared water-soluble platinum nano-water solution containing 0.02 g / mL with an average particle size of 5 nm, 2,4,7,9-tetramethyl-5-nonyne-4,7- Diol 0.40g, heat and ultrasonically disperse for 30 minutes, concentrate at a constant temperature of 70±1°C for 12 hours, cool to room temperature, add 3 mL of di-1,2-propanediol, ultrasonically disperse at room temperature for 5-10 minutes, and continue at a constant temperature of 50±1°C Ultrasonic heating and concentrating until the solution volume is about 10mL, the measured pH value is 6, which is not between 7 and 10, and sodium hydroxide is added to adjust the pH value to be between 7 and 10, that is, the platinum nanoparticle inkjet water-soluble ink is...

Embodiment 3

[0055] Example 3 Preparation of silver nanoparticle inkjet ink

[0056] Take 0.80 g of gelatin and add 10 mL of double distilled water. After mixing at 40°C, add 10 mL of glutaraldehyde solution with a mass concentration of 0.25% and stir and mix well to obtain a cross-linked compound of gelatin and glutaraldehyde. Add 0.50 g of potassium carbonate , heated to dissolve completely. After standing for 24 hours, add 1.00 g of prepared water-soluble silver nano-solid particles with an average particle size of 10 nm, and 0.40 g of 1,1,1-trimethylolpropane, and heat and ultrasonically disperse for 30 minutes. 1 ℃ constant temperature ultrasonic heating and concentration for 12 hours, after cooling to room temperature, add 3 mL of diethylene glycol, ultrasonically disperse at room temperature for 5 to 10 minutes, and continue ultrasonic heating and concentration at a constant temperature of 50 ± 1 ℃ until the solution volume is about 10 mL, and the pH value is measured. 6. If it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com