Method for preparing oligomeric acid potassium or oligomeric acid ammonium and application thereof

A technology of oligomeric acid and potassium polyacid, which is applied in the field of preparation of potassium oligomeric acid or ammonium oligomeric acid, can solve the problems such as no oligomeric acid salt, and achieves easy control of reaction conditions, strong growth regulation function, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057]Take 100 kg of dextran into a 300-liter reactor, add 150 kg of water, stir well, add 2 kg of glucosidase, adjust the pH value to 5.5, control the temperature at 40 ° C, stir and hydrolyze for 10 hours, and detect the molecular weight of 5000 Stop the reaction after about 10 minutes, filter to remove impurities, add 1% potassium permanganate to the filtrate, react at 80°C for 5 hours, stop the reaction with 1% vitamin C, remove impurities by sodium filtration and ion exchange, control the temperature below 10°C, add 5% potassium hydroxide, stop the salt-forming reaction when the pH value reaches 7.0, and spray dry to form solid yellow potassium oligoacid powder. The yield is greater than 85%.

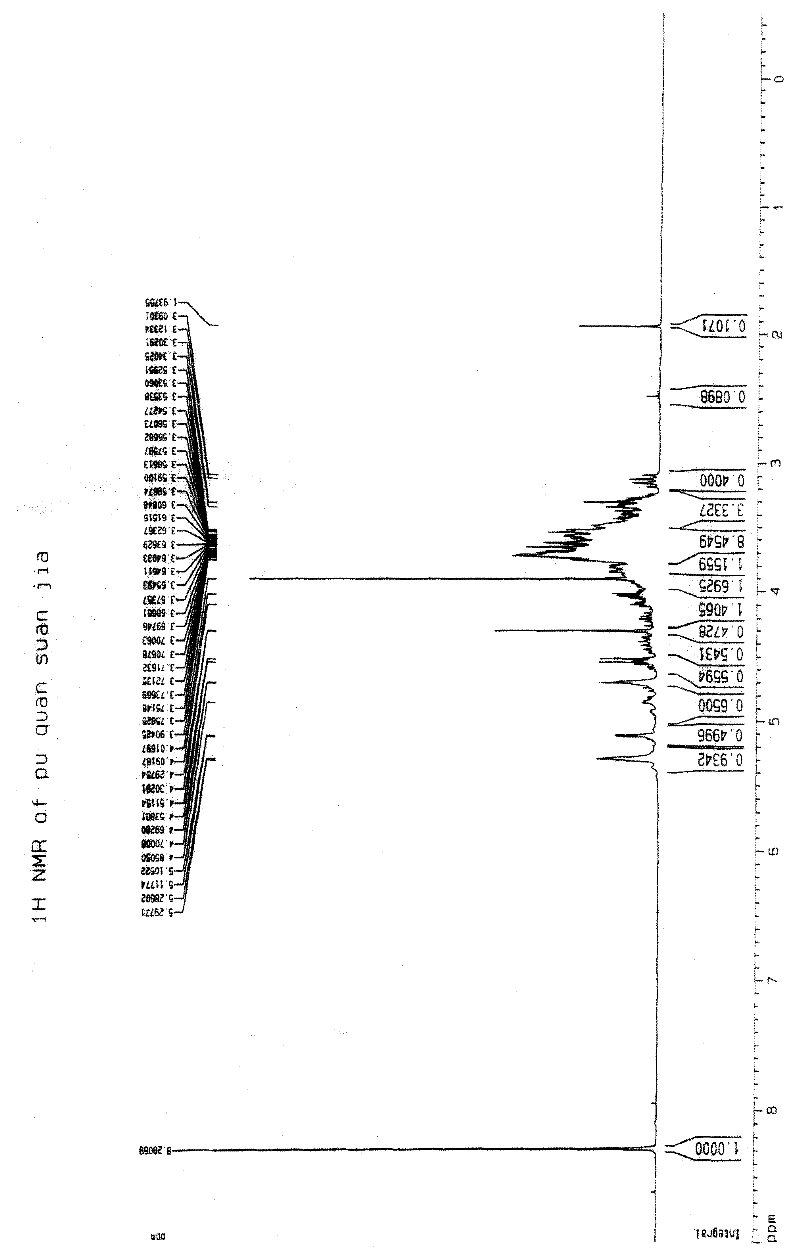

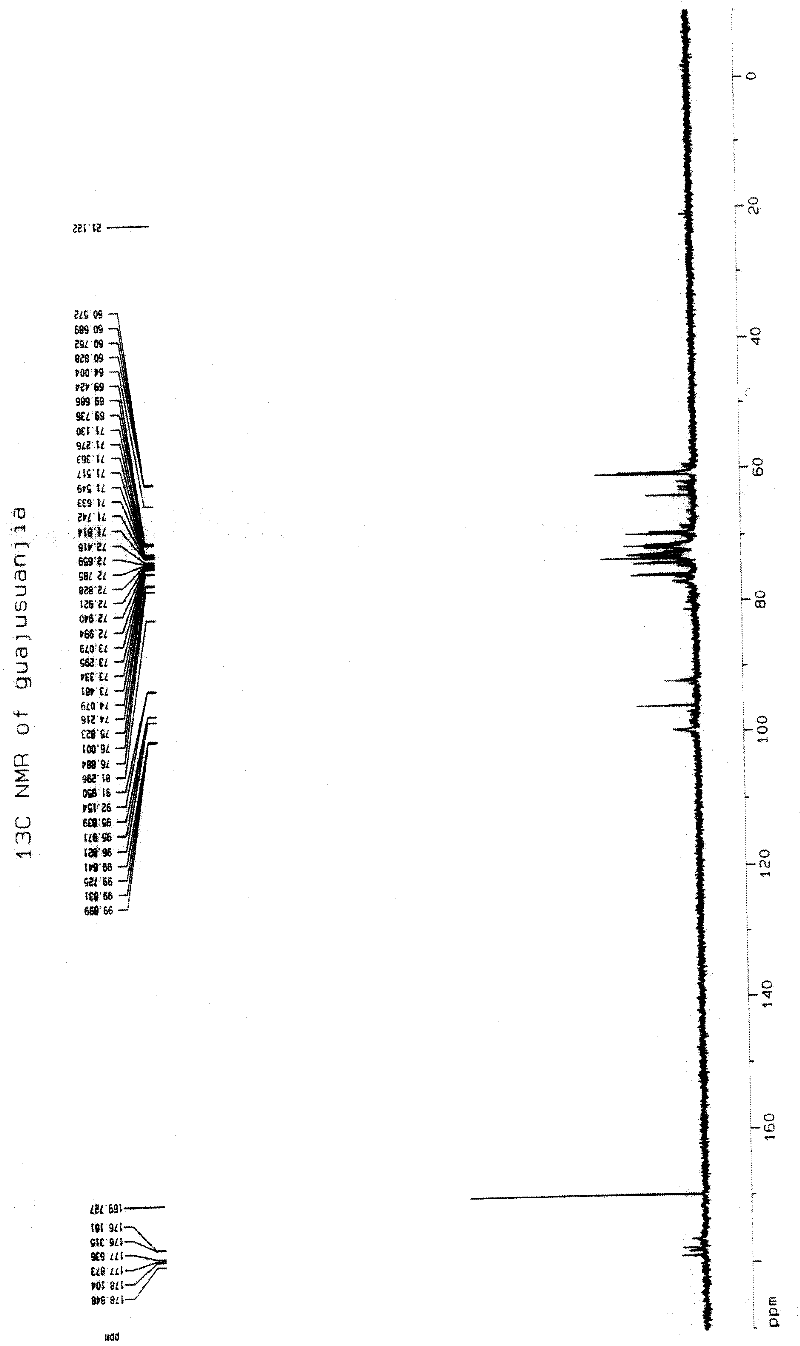

[0058] The prepared potassium oligoacid was analyzed by infrared spectrum and nuclear magnetic resonance.

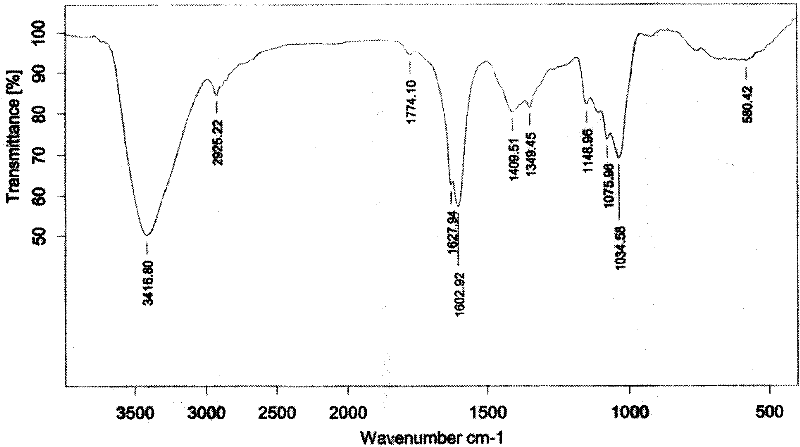

[0059] 1. Infrared spectral analysis:

[0060] The infrared spectrum analysis chart is attached figure 1 .

[0061] as attached figure 1 As shown, at 3416.80cm -1 The h...

Embodiment 2

[0069] 1. Select cellulose, lignin and hemicellulose as raw materials for extracting dextran, and grind the raw materials to 50 mesh;

[0070] 2. Acid leaching: Soak the pulverized dextran raw material with 0.5% sulfuric acid with a mass percentage concentration of 5 times that of the dextran raw material at a temperature of 25°C for 24 hours, and soak the dextran after acid leaching Wash with water until the pH value is neutral, and dry at 60°C;

[0071] 3. Alkali leaching: add sodium hydroxide with a mass percentage concentration of 20%, the weight of sodium hydroxide is 8 times that of dextran, soak at 40°C for 20 hours; wash the dextran after alkali leaching with water until the pH value is neutral , drying at 60°C;

[0072] 4. 200-mesh crushing to obtain clean dextran;

[0073] 5. Add the pretreated dextran to the water with the same weight as the dextran to moisten and soak, adjust the pH value to 4, add 1% dextran by weight to the dextran, and react at 30°C for 20 hou...

Embodiment 3

[0078] 1. Select beer yeast cell wall polysaccharide as the raw material for extracting glucan, and grind the raw material to 100 mesh;

[0079] 2. Acid leaching: soak the pulverized dextran raw material with 10% hydrochloric acid with a mass percentage concentration of 4 times that of the dextran raw material at a temperature of 50°C for 3 hours; wash with water until the pH value is neutral, Dry at 80°C;

[0080] 3. Alkaline leaching: add sodium hydroxide with a concentration of 50% by mass and 7 times the weight of dextran, soak at 90°C for 8 hours; wash with water until the pH value is neutral, and dry at 80°C;

[0081] 4. 300 mesh crushed to obtain clean dextran;

[0082] 5. Soak the pretreated glucan in water with a weight ratio three times that of the dextran, adjust the pH to 7, add glucan sidase with a weight of 5% of the dextran, and react at 50°C for 3 hours. Heat up to 100°C for 2 hours to terminate the reaction, filter, concentrate the oligosaccharide concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com