Continuous metallic glass fiber and preparing method thereof

A metal glass fiber and gold-based technology, applied in the field of continuous metal glass fiber and its preparation, can solve the problems of high production process cost, uneven diameter, material fracture, etc., and achieve excellent mechanical properties and excellent electrical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

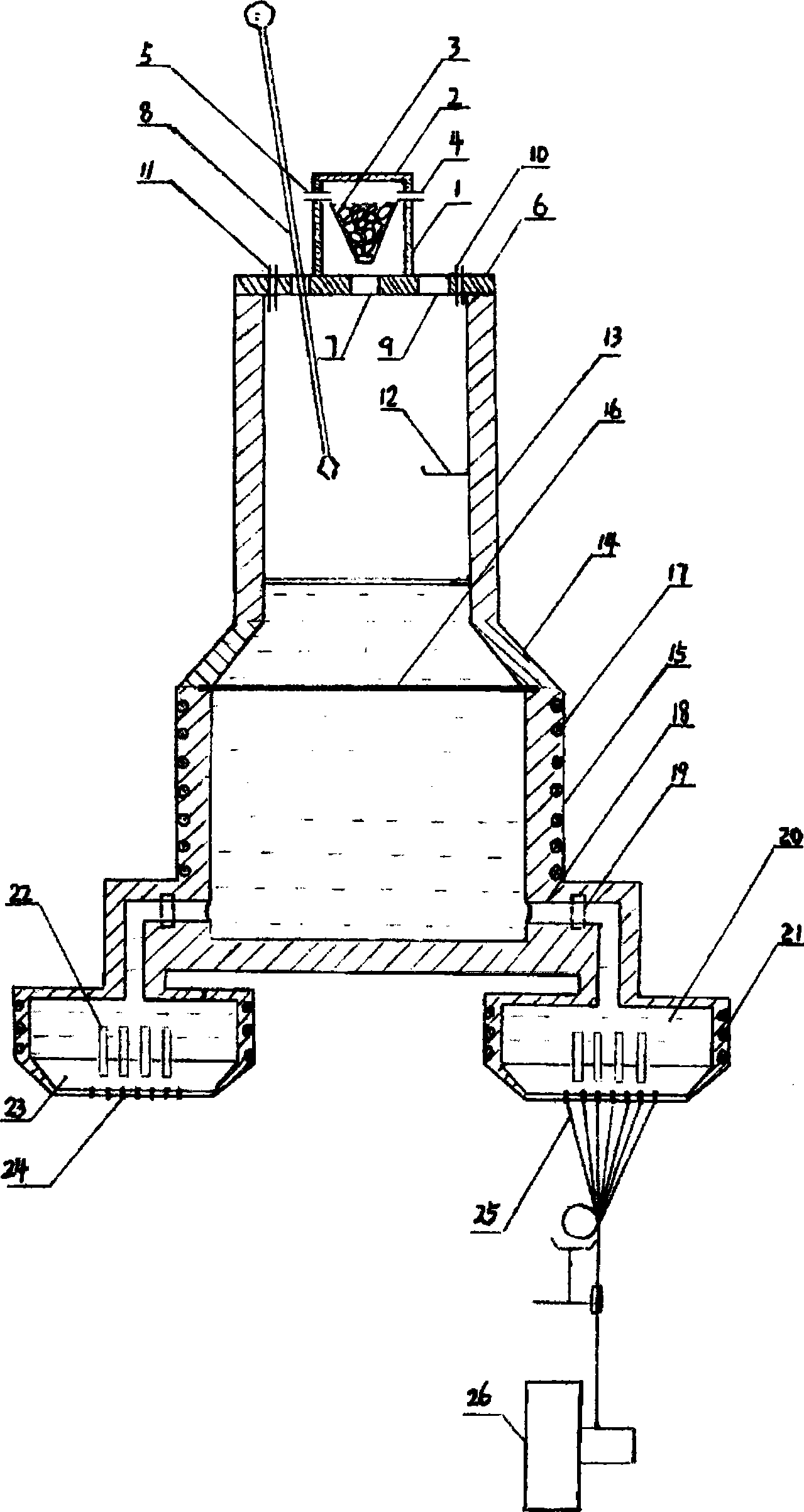

Method used

Image

Examples

Embodiment 1

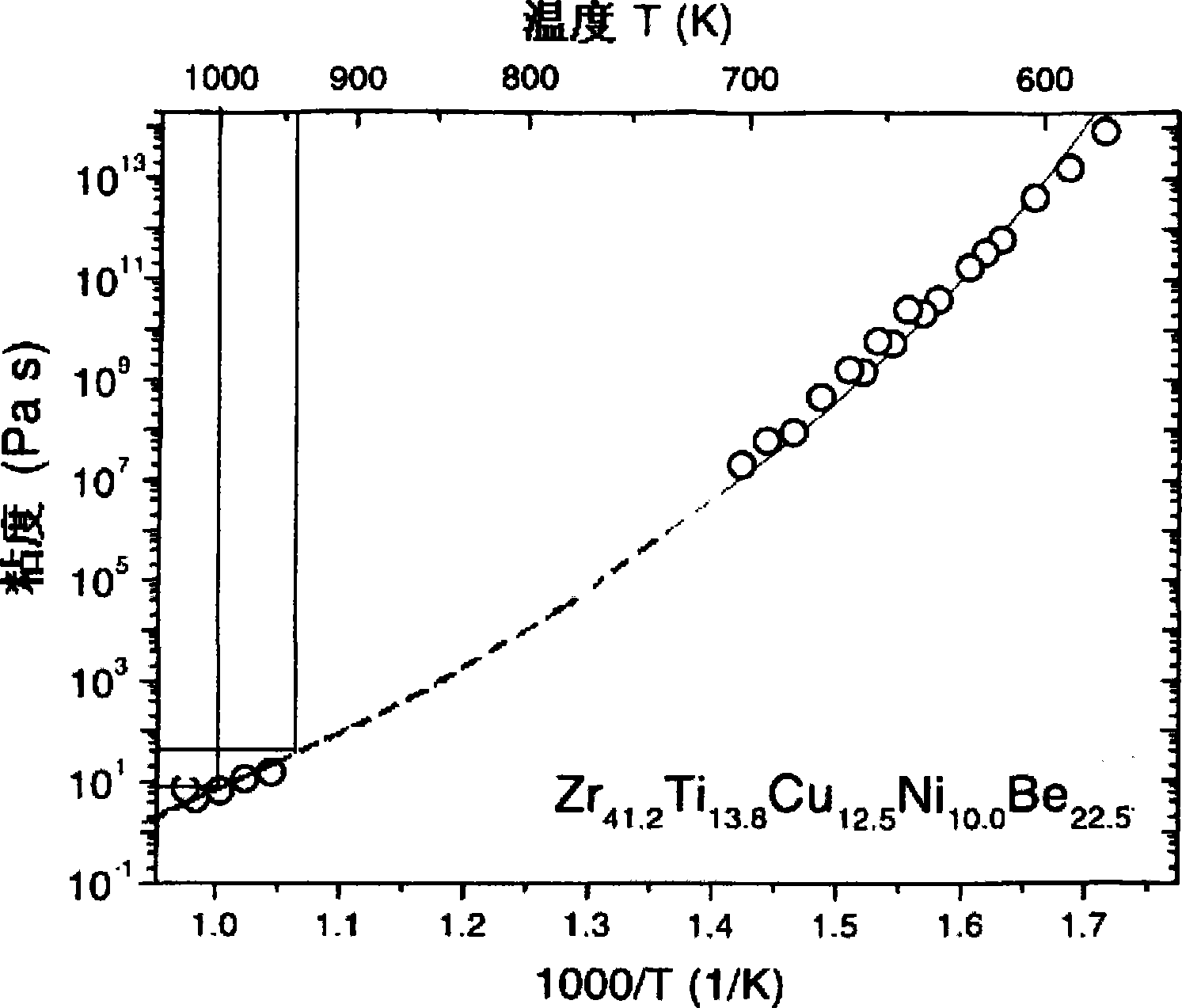

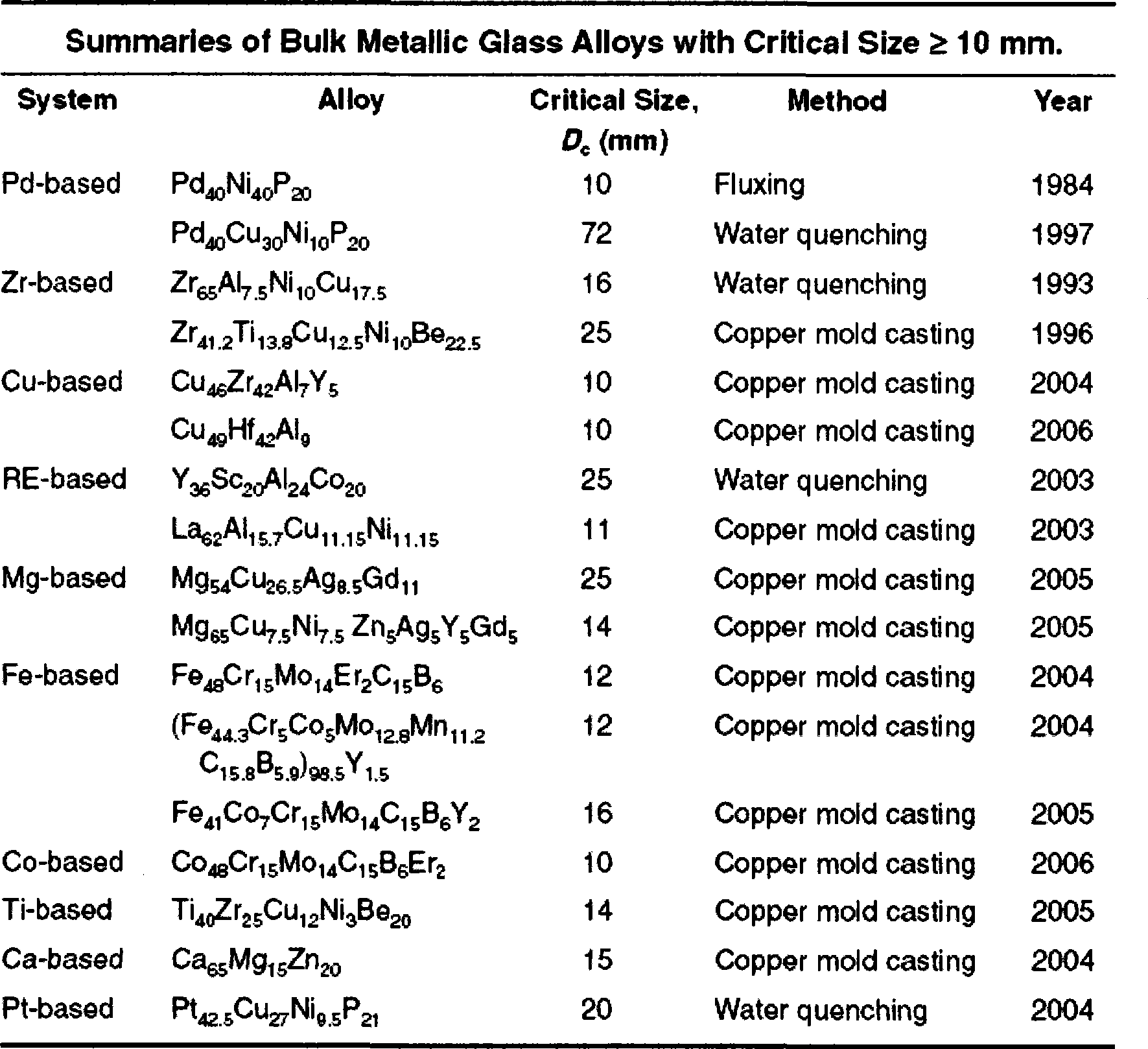

[0085] Example 1: The glass forming ability is 25mm (the critical cooling rate is about 1K / s), and the composition is Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 (Atomic Ratio) Preparation of Continuous Zirconium-Based Metallic Glass Fibers.

[0086] Commercially available pure metal Zr, Ti, Cu, Ni, Be elements such as rods, blocks, ingots, plates and other bulk materials (purity higher than 99.8% by weight) are used as starting materials, under the protection of argon gas purified by titanium Zr, Ti, Cu, Ni, and Be five-element alloys in a certain ratio are smelted by water-cooled copper crucible arc melting in a sealed vacuum furnace under the ground, and smelted 3 to 4 times to obtain a five-element "master alloy" ingot with uniform composition. After the oxide film on the surface of the smelted "master alloy" ingot is polished off and crushed to a certain suitable particle size, it can be used as a raw material for subsequent processes.

[0087] Under the condition that the...

Embodiment 2

[0090] Example 2: The glass forming ability is 25mm (the critical cooling rate is about 1K / s), and the composition is Mg 54 Cu 26.5 Ag 8.5 Gd 11 (Atomic Ratio) Preparation of Continuous Magnesium-based Metallic Glass Fibers.

[0091] Using commercially available pure metal elements such as rods, blocks, ingots, and plates of Mg, Cu, Ag, and Gd (purity higher than 99.5%, weight percent) as starting materials, firstly under the protection of argon gas purified by titanium A certain ratio of Cu, Ag, and Gd ternary alloys is melted in a water-cooled copper crucible as an "master alloy" in a sealed vacuum furnace for 3 to 4 times, and then the Cu-Ag-Gd "master alloy" is mixed with a certain The proportioned Mg is induction smelted in an inert atmosphere into a quaternary "master alloy" ingot with uniform composition. After grinding off the oxide skin on the surface of the smelted "master alloy" ingot and breaking it to a certain suitable particle size, it can be used as a raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com