Method for preparing dual-sensitivity graft copolymer with chitosan as main chain

A technology of graft copolymer and chitosan, which is applied in the fields of polymer materials and biomedical engineering, can solve problems such as single function, poor solubility, and failure to meet application requirements, and achieve the effect of wide sources and simple and easy synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 5 grams of chitosan, disperse and dissolve it with N,N-dimethylformamide, add 15 grams of triethylamine, add 30 grams of 2-bromoisobutyryl bromide dropwise at 0°C, and drop it in 20 minutes. And react at 10°C for 72 hours. After desalination by suction filtration, precipitation with deionized water, and vacuum drying, a bromine-terminated chitosan macromolecular initiator was obtained. Weigh 0.5 g of bromo-terminated chitosan macroinitiator and dissolve it in N,N-dimethylformamide, add methacrylic acid-N,N-dimethylaminoethyl ester 3 g, then add initiator bromination Cuprous (80 mg) / hexamethyltriethylenetetramine (150 mg) was vacuum-filled three times with nitrogen, and reacted in an oil bath at 20° C. for 48 hours under nitrogen protection. The product was dialyzed with deionized water and freeze-dried to obtain a double-sensitive graft copolymer with chitosan as the main chain.

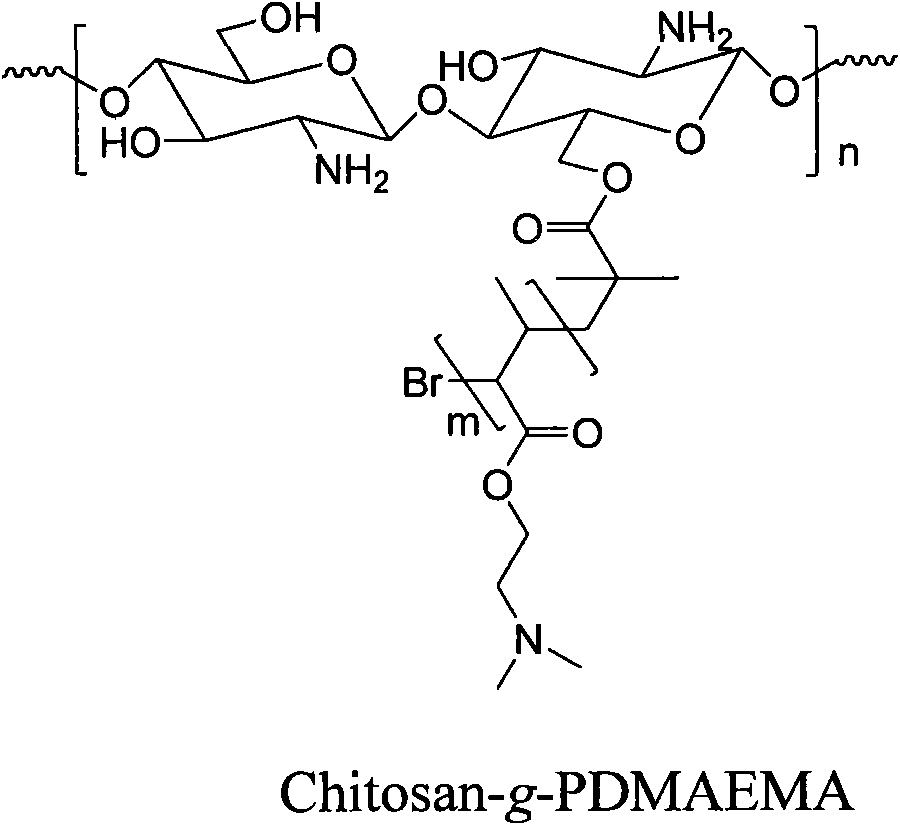

[0020] The representative structural formula of the dual-sensitivity graft copolym...

Embodiment 2

[0022] Weigh 5 grams of chitosan, disperse and dissolve it with N, N-dimethylformamide, add 20 grams of diethylamine, add 40 grams of 2-bromopropionyl bromide dropwise at 5 ° C, drop it in 30 minutes, and The reaction was carried out at 15°C for 60 hours. After desalination by suction filtration, precipitation with deionized water, and vacuum drying, a bromine-terminated chitosan macromolecular initiator was obtained. Weigh 0.5 g of bromo-terminated chitosan macroinitiator and dissolve it in N,N-dimethylacetamide, add methacrylic acid-N,N-dimethylaminoethyl 4 g, then add the initiator for chlorination Cuprous (90 mg) / bipyridine (160 mg) was vacuum-filled three times with nitrogen, and reacted in an oil bath at 40° C. for 36 hours under nitrogen protection. The product was dialyzed with deionized water and freeze-dried to obtain a double-sensitive graft copolymer with chitosan as the main chain.

Embodiment 3

[0024] Weigh 5 grams of chitosan, disperse and dissolve it with N,N-dimethylacetamide, add 18 grams of pyridine, add 36 grams of 2-bromoisobutyryl bromide dropwise at 8°C, drop it in 40 minutes, and The reaction was carried out at 20°C for 48 hours. After desalination by suction filtration, precipitation with deionized water, and vacuum drying, a bromine-terminated chitosan macromolecular initiator was obtained. Weigh 0.5 g of bromo-terminated chitosan macroinitiator and dissolve it in N, N-diethylformamide, add methacrylic acid-N, N-dimethylaminoethyl 6 g, then add initiator bromination Cuprous (100 mg) / bipyridine (180 mg) was vacuum-filled three times with nitrogen, and reacted in an oil bath at 50° C. for 10 hours under nitrogen protection. The product was dialyzed with deionized water and freeze-dried to obtain a double-sensitive graft copolymer with chitosan as the main chain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com