Acid beta-mannase, genes, engineering bacteria and structure thereof

A mannanase and engineering bacteria technology, applied in the field of genetic engineering, can solve the problems of low yield of mannanase and the like, and achieve the effects of good heat resistance and wide enclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1. Obtaining the whole gene of β-mannanase from Aspergillus niger CBS 513.88

[0057] 1. Interception of gene fragments

[0058] Obtain the β-mannanase gene An15g07760 (see SEQ ID No.3) of Aspergillus nigerCBS 513.88 bacterial strain in NCBI database, analyze its sequence and optimize this gene sequence according to Pichia pastoris codon preference and mRNA structure, adopt SignalP 3.0 Server online analysis software analyzes the signal peptide of the protein encoded by the gene and excises the gene sequence encoding the signal peptide, adds an XhoI restriction site (C^TCGAG) and a CG protection base at the 5' end, and adds XbaI ( T^CTAGA) restriction site and protection base GC to obtain optimized β-mannanase gene (see SEQ ID No.4). Design three primers:

[0059] Fn-Man: GACCGCTCGAGAAGAGAGCTTCTAATC, see SEQ ID No.5;

[0060] Rn-Man1: GCTCTAGAGCAGCACCTTCCCAATTC, see SEQ ID No.6;

[0061] Rn-Man2: GCTCTAGAGCTTAAGCACCTTCCCAATTC, see SEQ ID No. 7.

[0062] The...

Embodiment 2

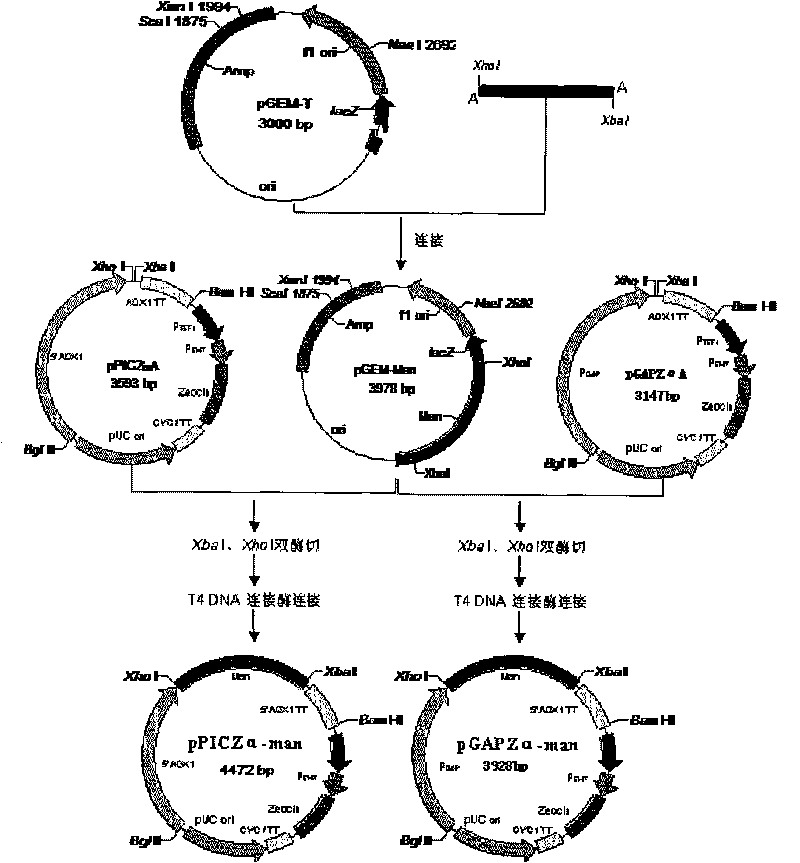

[0087] Embodiment 2, construction of Aspergillus niger β-mannanase expression engineering bacteria

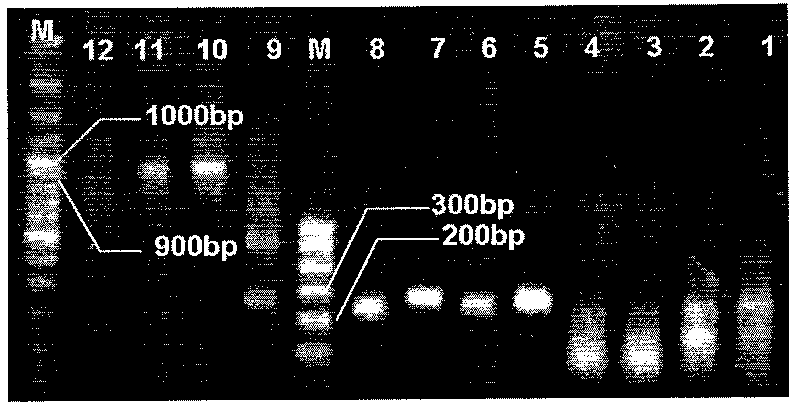

[0088] 1. Construction of β-mannanase gene amplification vector and gene amplification

[0089] The complete β-mannanase gene (see SEQ ID No.4) obtained by Assembly PCR and LCR was ligated into pGEM-T vector, and then transferred into DH5α competent cells by the same method as above. After the white spots were picked and identified as positive clones by colony PCR, they were sent to Shanghai Sunny Biotechnology Co., Ltd. for sequencing. The β-mannanase gene recombinant plasmid clone without mutation identified by sequencing was preserved for future use.

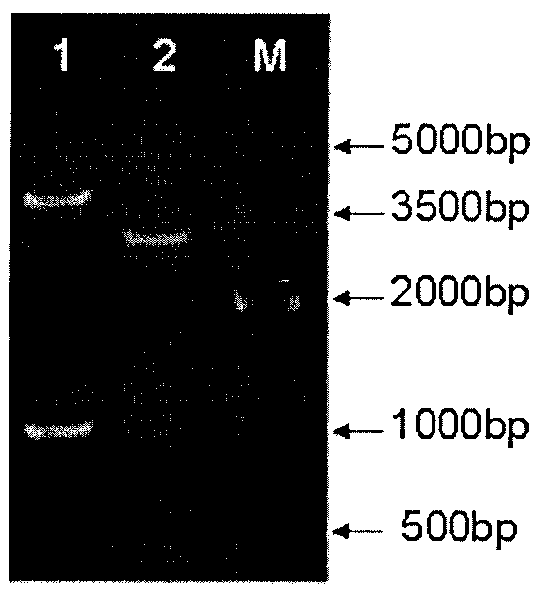

[0090] 2. Construction of β-mannanase gene Pichia pastoris expression vector

[0091] 1) Methanol-inducible expression vector pPICZα-man

[0092] Cultivate the DH5α clone of the recombinant β-mannanase gene, and extract pGEM-man by alkaline lysis (using the specific method described in the book "Molecular Cloning Experiment...

Embodiment 3

[0111] Embodiment 3, inducible expression of Aspergillus niger β-mannanase

[0112] Pick a stable recombinant monoclonal strain, inoculate it into a 250mL shake flask containing 25mL BMGY, and cultivate it to OD at 28-30°C, 250-300rpm 600 = 2-6 (about 16-18 hours). Inoculate 25mL medium into a 3L shake flask containing 1L BMGY, shake vigorously at 28-30 degrees (250-300rpm), until the logarithmic growth phase (OD 600 =2-6). Use a sterilized centrifuge tube and centrifuge at 1500-3000g at room temperature for 5min to collect the cells. Remove supernatant and resuspend cells to OD with BMMY 600 =1.0(2-6). Divide the medium into three 3L septum shaker flasks, cover with 2 layers of sterile gauze or cheese cloth, and put them in a shaker at 28-30°C to continue culturing. Every 24 hours, add methanol to a concentration of 0.5% until the optimal induction time is reached. Take bacterial liquid samples according to the time points ((24h, 48h, 60h, 72h, 96h), the sampling volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com