Epitaxial thin film used for high-dielectric constant gate dielectric and preparation method thereof

A technology of high dielectric constant and epitaxial thin film, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc. It can solve the problems of low crystallization, application limitations, large leakage current, etc., and achieve high dielectric constant and conduction band Effect of offset, stable thermodynamic properties, high crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

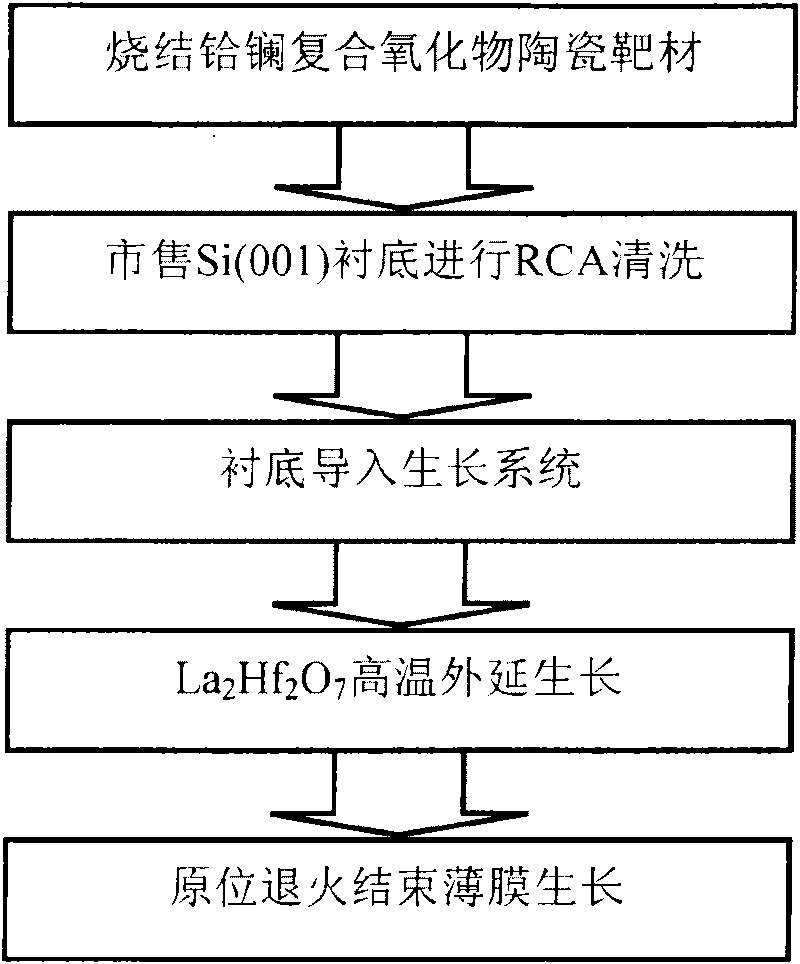

[0034] like figure 1 As shown in the technological process of the present invention, the preparation method of preparing high-k gate dielectric thin film material on Si(001) substrate is as follows:

[0035] 1. Sintered hafnium-lanthanum composite oxide ceramic target: first obtain a pyrochlore phase (A 2 B 2 o 7 ) hafnium-lanthanum composite oxide ceramic target. HfO with a purity of 99.9995% is first proportionally 2 with a purity of 99.9995% La 2 o 3 Mixing is carried out under the condition of high-purity ball milling (95-type zirconia balls), and then the powder is calcined at 600°C to obtain an average particle size of 500-800nm. Then the powder is pressed into a disc with a diameter of 40mm and a thickness of 4mm by uniaxial cold pressing and cold isostatic pressing, and is fully reacted and sintered at 1450-1550°C in an oxygen-containing atmosphere to form a dense ceramic target.

[0036] 2. RCA cleaning of commercially available Si(001) substrates: Surface trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com