Method for preparing porous metal oxide-coated carbon nanotube composite material

A composite material and porous metal technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of pollution, versatility, low output, etc., and achieve excellent electrochemical energy storage, high output, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

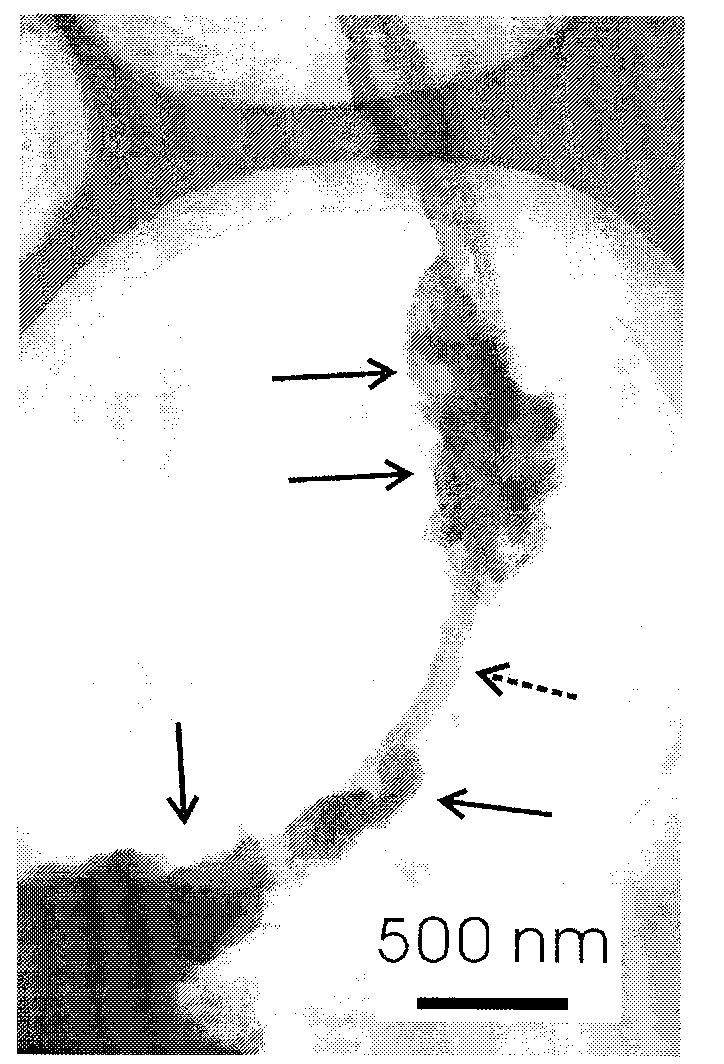

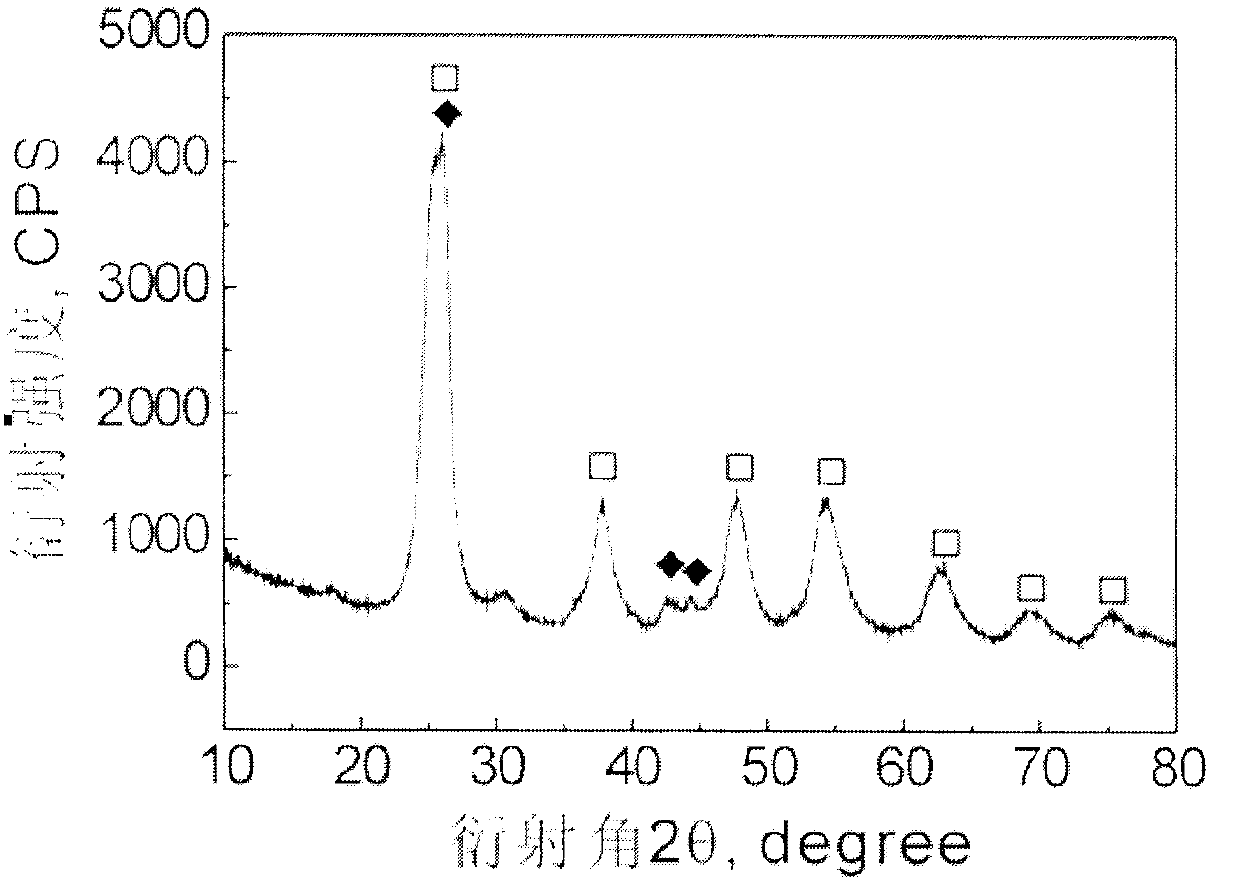

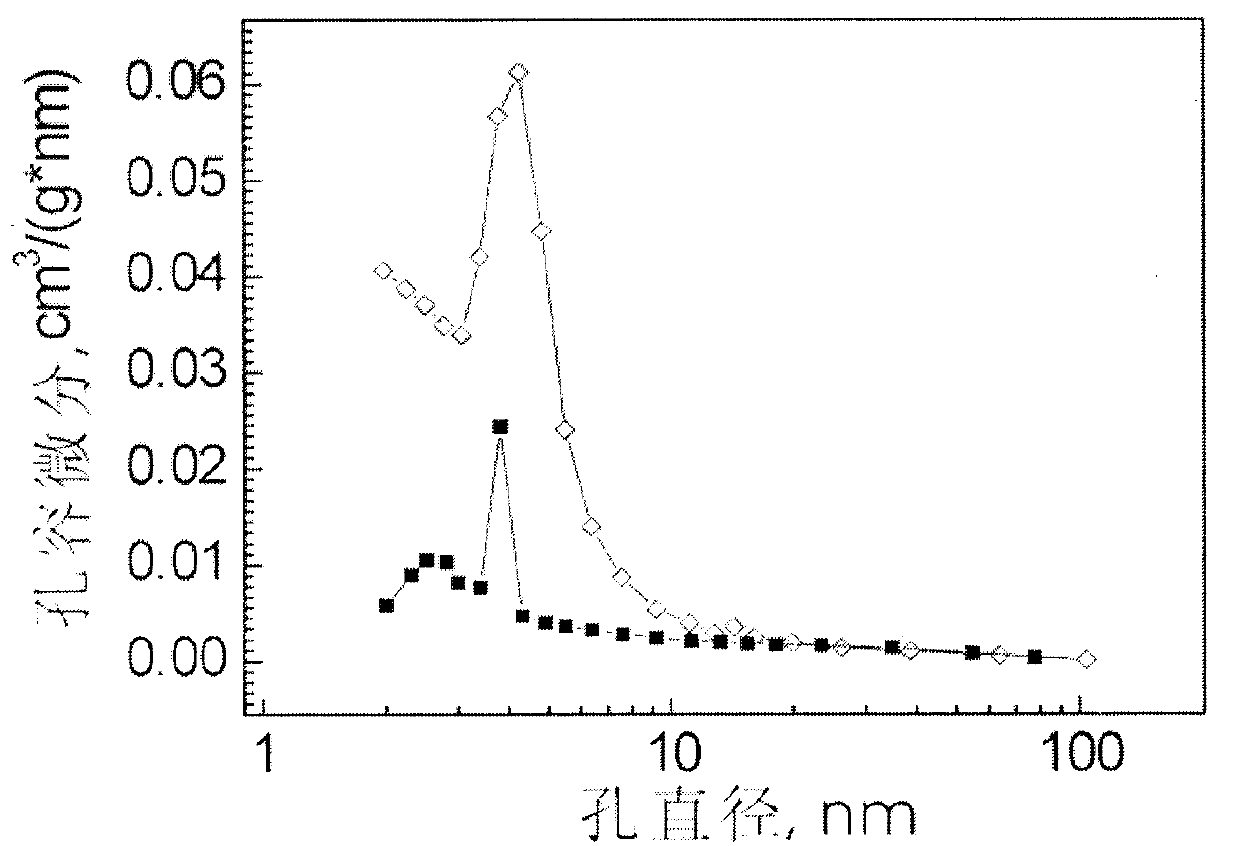

[0031] Specific Embodiment 1: In this embodiment, the method for preparing porous metal oxide-coated carbon nanotube composite material is carried out according to the following steps: 1. Add 0.5-800 mg of metal salt to each milliliter of polyol, and heat the mixture under the condition of 50-180 ° C. 2. Prepare the solution according to the volume ratio of water and organic solvent 0:100-30:100, add 0.1-10 mg of carbon nanotubes to each milliliter of the solution, and then ultrasonically disperse to obtain Carbon nanotube dispersion; 3. Stir and mix the metal oxide precursor solution and the carbon nanotube dispersion at a volume ratio of 1:10 to 1:0.1 for 0.2 to 20 hours, and then centrifuge at 3000 to 4000 r / min for 1 to 20 hours. For 10 minutes, wash and centrifuge the resulting precipitate with ethanol, and then dry it by blowing at room temperature to obtain the polymer precursor of the metal oxide coated carbon nanotube composite; 4. The polymer precursor of the metal ox...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the acetylacetonate salt in step one is scandium acetylacetonate, titanium acetylacetonate, vanadium acetylacetonate, chromium acetylacetonate, manganese acetylacetonate, iron acetylacetonate, acetylacetonate Cobalt acetonate, nickel acetylacetonate, copper acetylacetonate, zinc acetylacetonate, aluminum acetylacetonate, gallium acetylacetonate, yttrium acetylacetonate, zirconium acetylacetonate, molybdenum acetylacetonate, ruthenium acetylacetonate, cadmium acetylacetonate, indium acetylacetonate, tin acetylacetonate , hafnium acetylacetonate, tantalum acetylacetonate, iridium acetylacetonate, thallium acetylacetonate, lead acetylacetonate, lanthanum acetylacetonate, cerium acetylacetonate, praseodymium acetylacetonate, neodymium acetylacetonate, samarium acetylacetonate, europium acetylacetonate, gadolinium acetylacetonate, acetylacetonate Terbium acetylacetonate, dyspro...

specific Embodiment approach 3

[0037] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 to 2 is that the polyol in step 1 is composed of one or more of ethylene glycol, glycerol or diethylene glycol.

[0038] In this embodiment, when the polyols are a mixture, various polyols can be mixed in any ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com