Flexible dye-sensitized solar cell

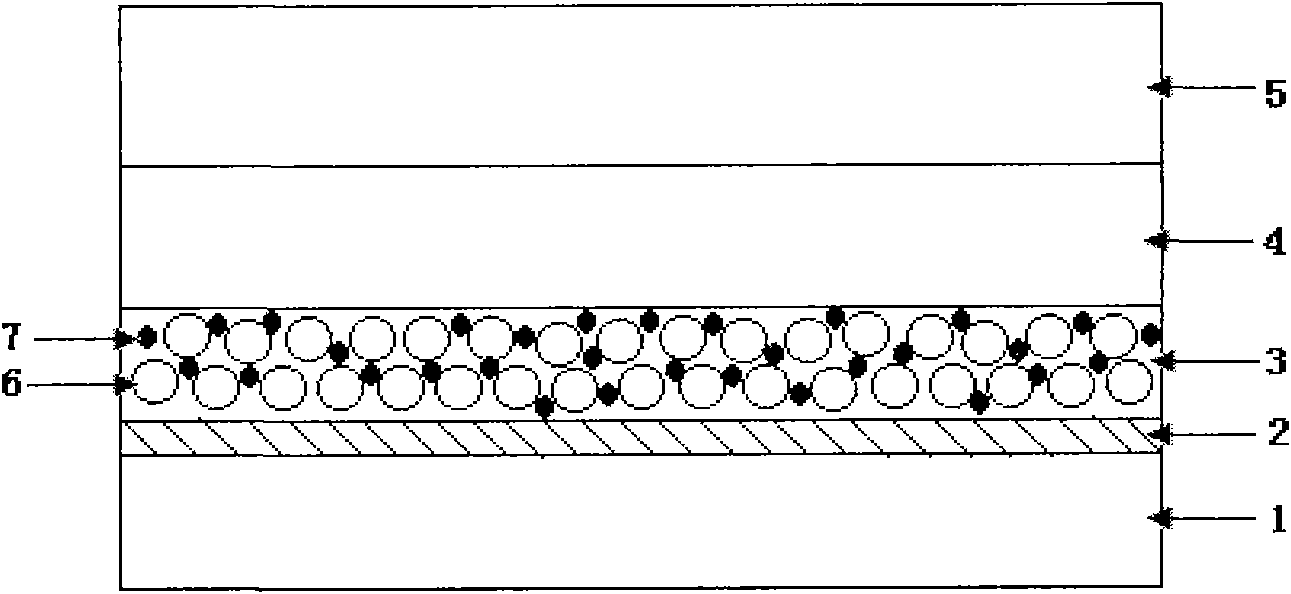

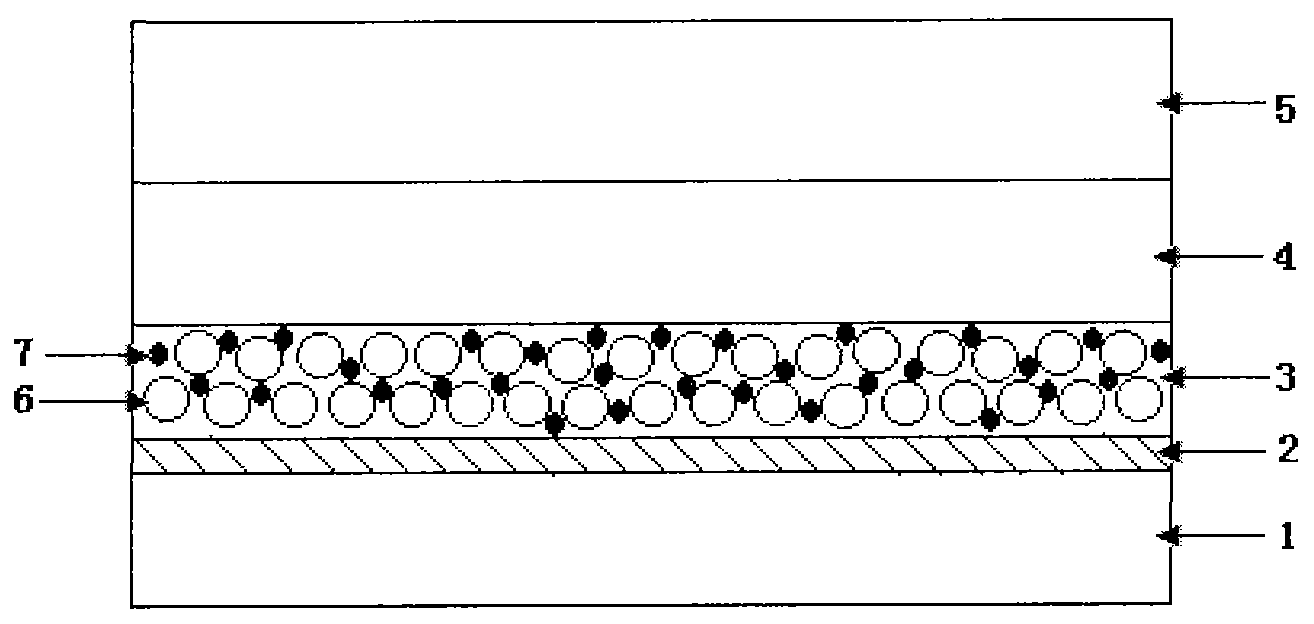

A technology for solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of poor flexibility, affecting the photoelectric performance and service life of the cells in the preparation process of the flexible DSSC photoanode, and complicated processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

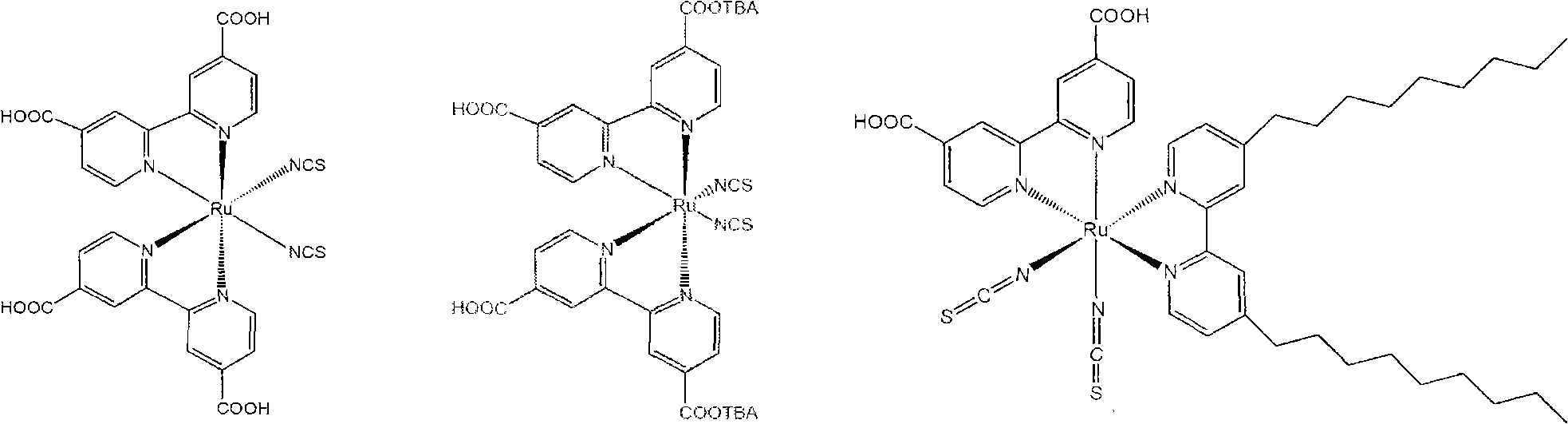

[0042] Select a PET substrate with a thickness of 175 μm, wash it with detergent and absolute ethanol, and coat a layer of polythiophene conductive layer with a thickness of 1 μm on its surface to obtain a sheet resistance of 15Ω / □ and visible light transmittance 78% organic conductive polymer film. The selected polythiophene conductive polymer is a mixture of CLEVIOS PH500 and CLEVIOS PH1000 produced by Bayer, and its preparation method can adopt the method disclosed in the above-mentioned patent.

[0043] The nano titanium dioxide P25 powder that takes 2.4g Degussa production is put into the mortar that fills a certain amount of n-butanol, then add 10g of ethyl cellulose with the same content as 10% n-butanol solution and 5g PEG20000 with a solid content of 20% Methanol solution, mix well and grind for 4h to make TiO 2 slurry. It was printed on the conductive layer of the organic conductive polymer film, and after natural drying, a TiO with a thickness of about 12 μm was o...

Embodiment 2

[0047]Select a PET substrate with a thickness of 188 μm, wash it with detergent and absolute ethanol, and coat a layer of polyaniline conductive layer with a thickness of 2 μm on its surface to obtain a sheet resistance of 23Ω / □ and visible light transmittance. 75% organic conductive polymer film, its specific preparation method: polyaniline conductive polymer (Wuhan Yuancheng Nanjian Technology Development Co., Ltd.) is placed in acetonitrile, isopropanol and titanium tetrachloride mixed solution, acetonitrile, isopropanol and The volume ratio of titanium tetrachloride is 1:2:1, electric stirring for 2 hours, ultrasonic dispersion for 20 minutes, polyaniline is fully dispersed in acetonitrile, isopropanol and titanium tetrachloride mixed solvent, wherein, polyaniline and mixed solvent The mass ratio is 1:50, and then the residual oxidant and polymerized monomers in the polyaniline are removed by filtration, and then dried for use. At room temperature, the polyaniline after th...

Embodiment 3

[0052] Select a PET substrate with a thickness of 125 μm, wash it with detergent and absolute ethanol, and coat a layer of polythiophene conductive layer with a thickness of 0.8 μm on its surface to obtain a sheet resistance of 15Ω / □ and visible light transmission. rate of 83% organic conductive polymer film. The selected polythiophene conductive polymer is a mixture of CLEVIOS PH750 and CLEVIOS PH1000 produced by Bayer, and its preparation method can adopt the method disclosed in the above-mentioned patent.

[0053] Weigh 3.6g of 1mol / L tetrabutyl titanate n-butanol solution and 0.8g of Degussa's nano-titanium dioxide P25 powder and stir for 4h to obtain TiO 2 colloid. It was printed on the conductive layer of the organic conductive polymer film, and after natural drying, a TiO with a thickness of about 14 μm was obtained. 2 film. Then it was boiled in pure water at 100°C for 4h to obtain nano-TiO 2 porous film. TiO will be produced 2 The porous film is dipped into a 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com