Biological denitrifier and application thereof

A technology of denitrification and biological activity, applied in the field of microorganisms, can solve the problems of long treatment time, low efficiency, lack of tolerance to high-concentration ammonium salts, etc., and achieve good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

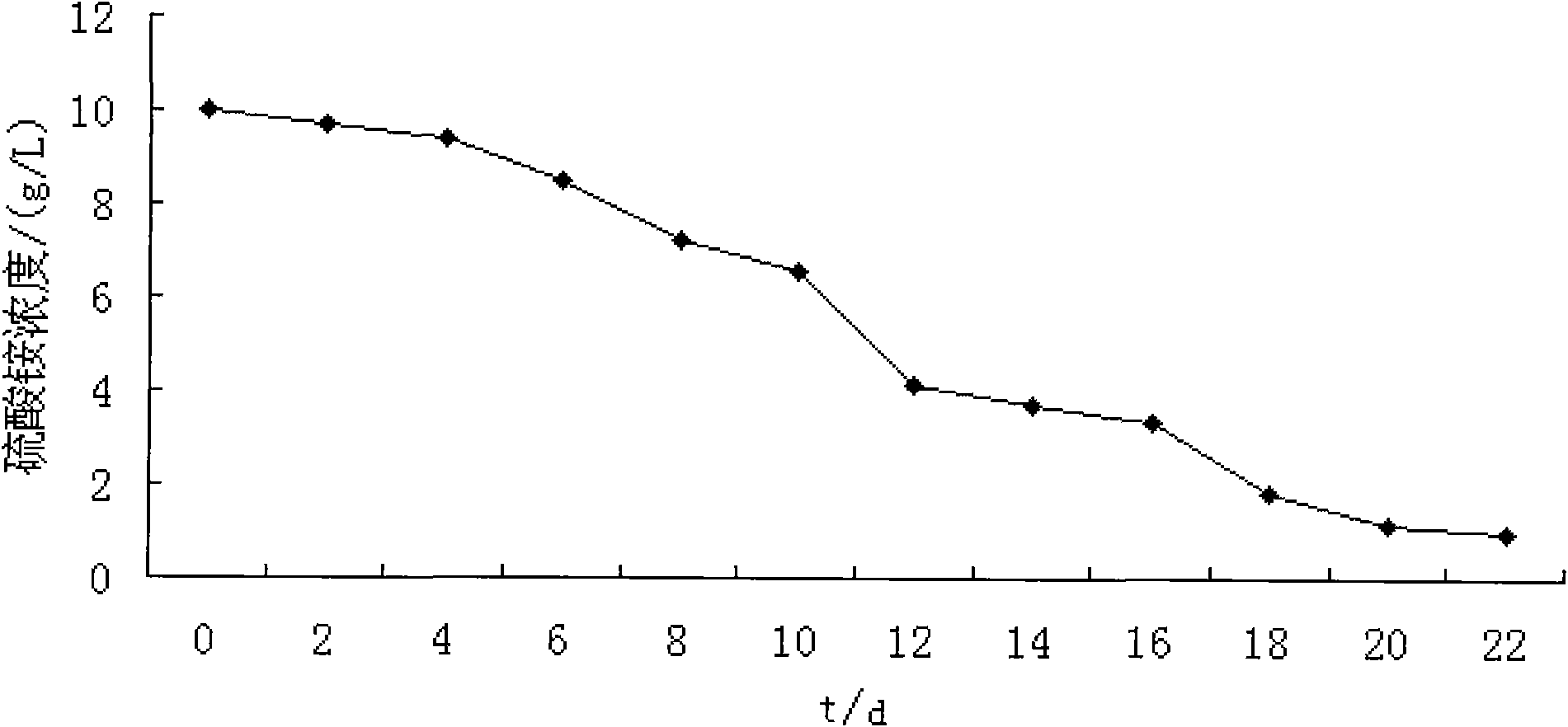

[0044] Ammonia nitrogen removal ability of CPU BS-1 for simulated ammonium-containing wastewater

[0045] 1. Determination of ammonia nitrogen in medium by indophenol blue method

[0046] 1.1 Ammonium standard solution preparation:

[0047] Precisely measure 0.2358g of ammonium sulfate dried to constant weight at 105°C, dissolve in an appropriate amount of double-distilled water, transfer to a 100mL volumetric flask, and then set the volume to the mark. That is, the mother liquor containing 500 μg / mL of ammonium. Accurately dilute 10 times before use.

[0048] 1.2 Reagent A:

[0049] Accurately weigh 5.0000g of phenol and 0.0290g of ferrous sodium ferricyanide (dihydrate) and dissolve in double distilled water, dilute to 500mL, and store in a brown bottle at 4°C.

[0050] 1.3 Reagent B:

[0051] Weigh 2.50g of sodium hydroxide, 2.0g of trisodium citrate and 3.5mL of sodium hypochlorite, dissolve them in double distilled water, dilute to 500mL, and store in a brown bottle ...

Embodiment 2

[0064] Preparation of freeze-dried powder and determination of viable bacteria concentration

[0065] 1. Preparation of freeze-dried powder

[0066]Add 15% (m / v) skimmed milk powder to the fermentation broth of Bacillus subtilis CPU BS-1, pre-freeze in the cold trap of a lyophilizer for 7h-8h, and dry in a vacuum in a lyophilizer. The first stage is -30°C for 240min (4h), the second stage is -10°C for 600min (10h), the third stage is 0°C for 960min (16h), and the fourth stage is 4°C for 360min (6h).

[0067] 2. Determination of the concentration of live bacteria in freeze-dried powder

[0068] The lyophilized powder was used to determine the concentration of viable bacteria, and diluted with starch to an appropriate concentration.

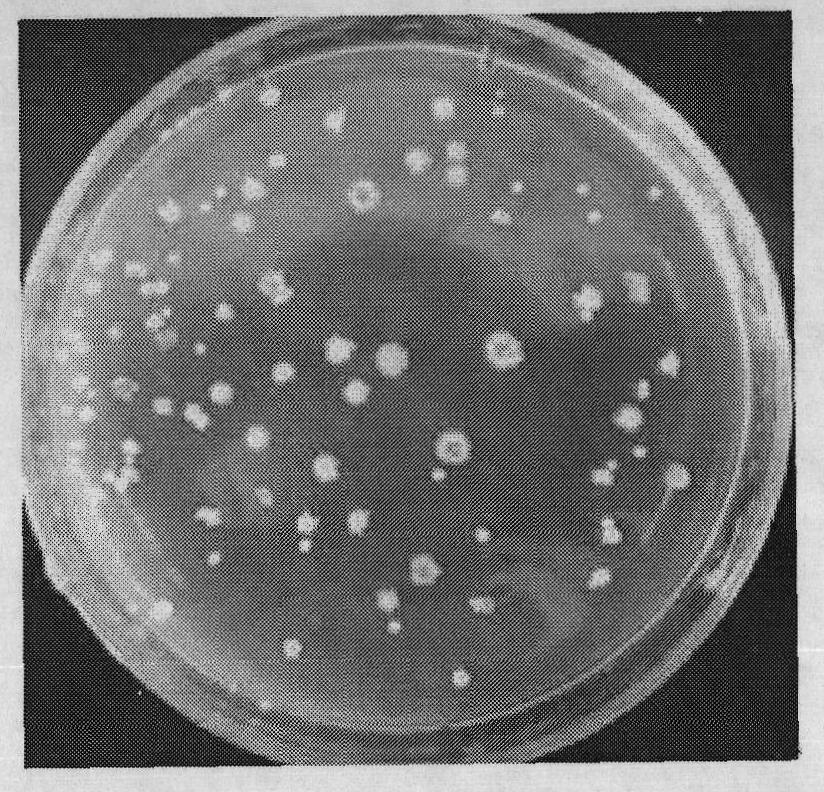

[0069] The bacteria count reporting rules should select the average bacterial colony count between 30 and 300 as the basis for the bacteria count report (taking two significant figures).

[0070] 2.1 When the number of colonies in only one dilut...

Embodiment 3

[0076] Large-scale cultivation of Bacillus subtilis CPU BS-1 in fermenter

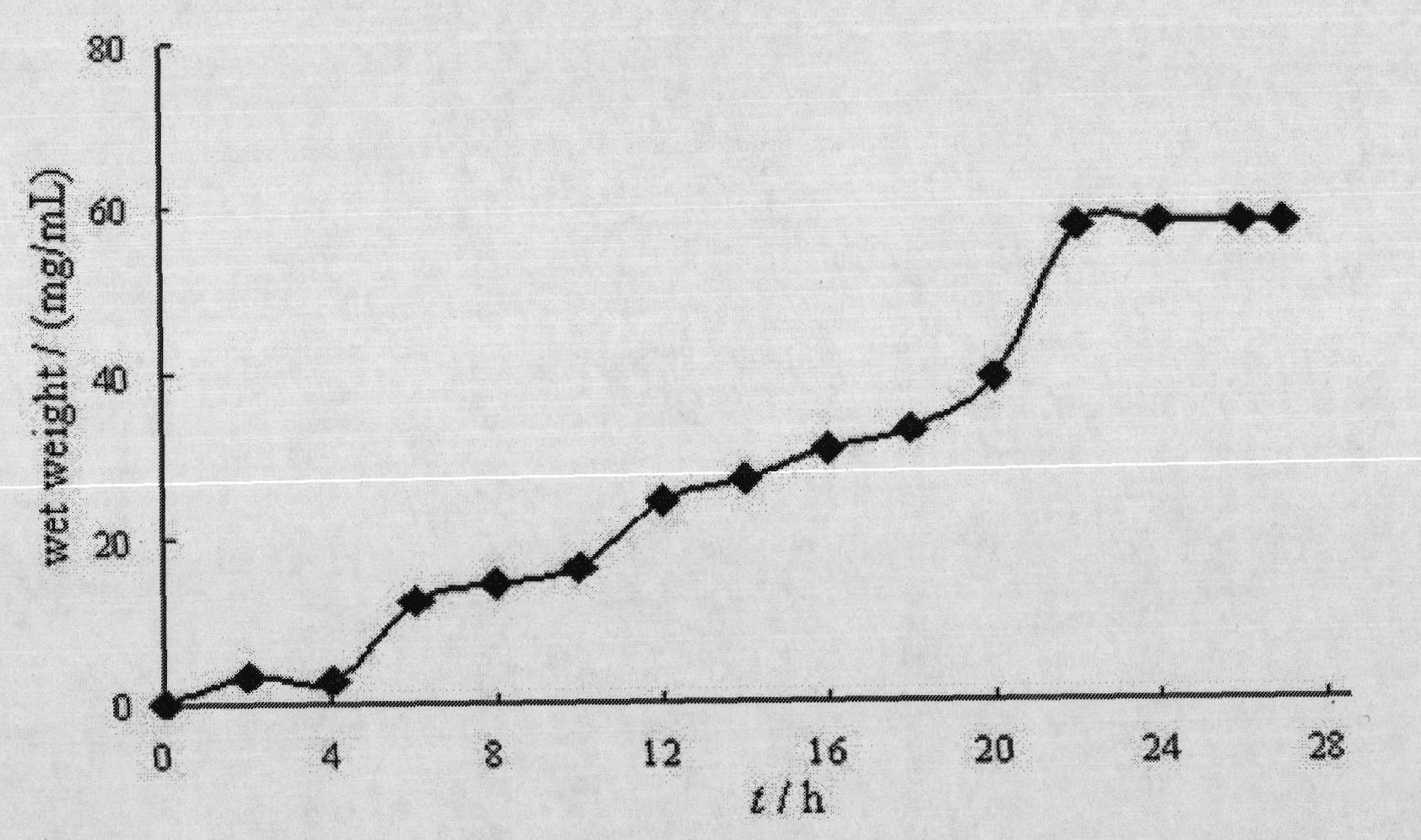

[0077] Two rings of bacterial lawn were taken from the agar slant and put into a 250ml Erlenmeyer flask with 50ml of seed medium, and cultured at 37°C and 200rpm on a shaker for 12h. Inoculate according to 5% inoculum amount, and transfer 500ml of seed culture solution to a 10L fermenter equipped with 9.5L of fermentation medium. According to the research result of shake flask experiment, determine the culture condition of optimum fermentor: 37 ℃, stirring speed 100rpm, ventilation rate 0.07vvm, inoculation amount 5%, fermentation medium composition (g / L): glucose 160g, corn steep liquor 40g, urea 20g, soybean cake powder 5g, calcium carbonate 5g, the initial pH was adjusted to 7.2, and the strain grew into a plateau after 24h. After culturing for 24 hours, a higher concentration of bacteria can be harvested, which is conducive to large-scale use in practical applications. Growth curve see attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com