Spongy quantum dot solar cell and preparation method thereof

A technology of solar cells and quantum dots, applied in the field of solar cells, can solve the problems of low light absorption efficiency, difficult hole transport, large loss of photo-generated electron transport, etc., and achieve the effects of simple preparation process, short reaction time and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

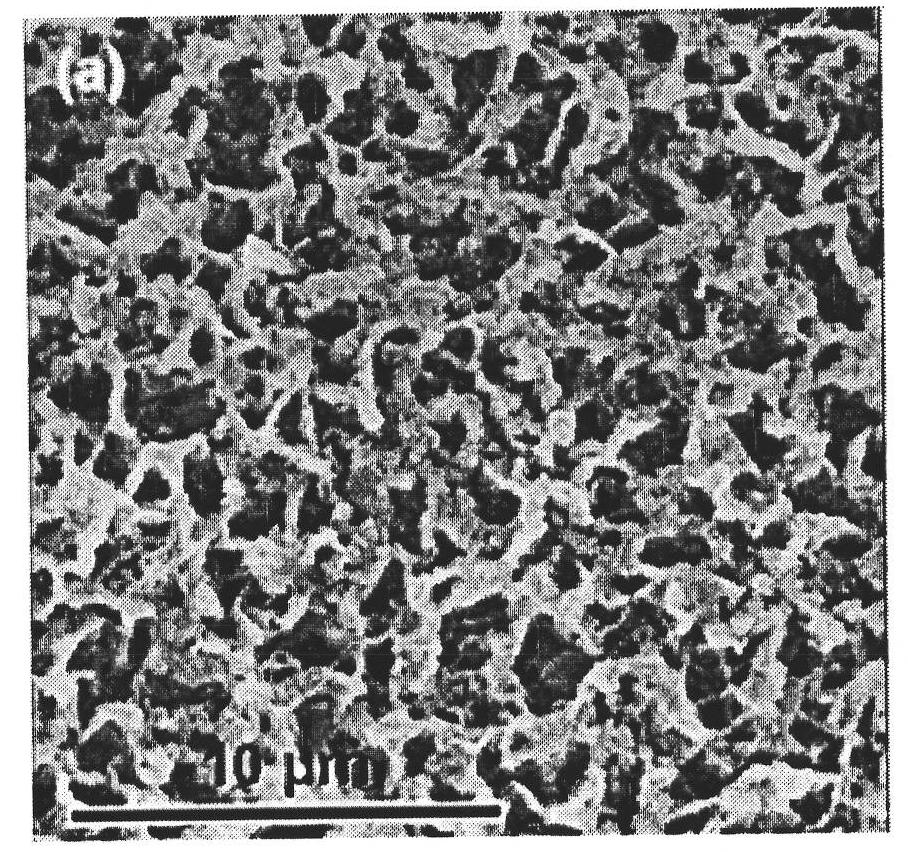

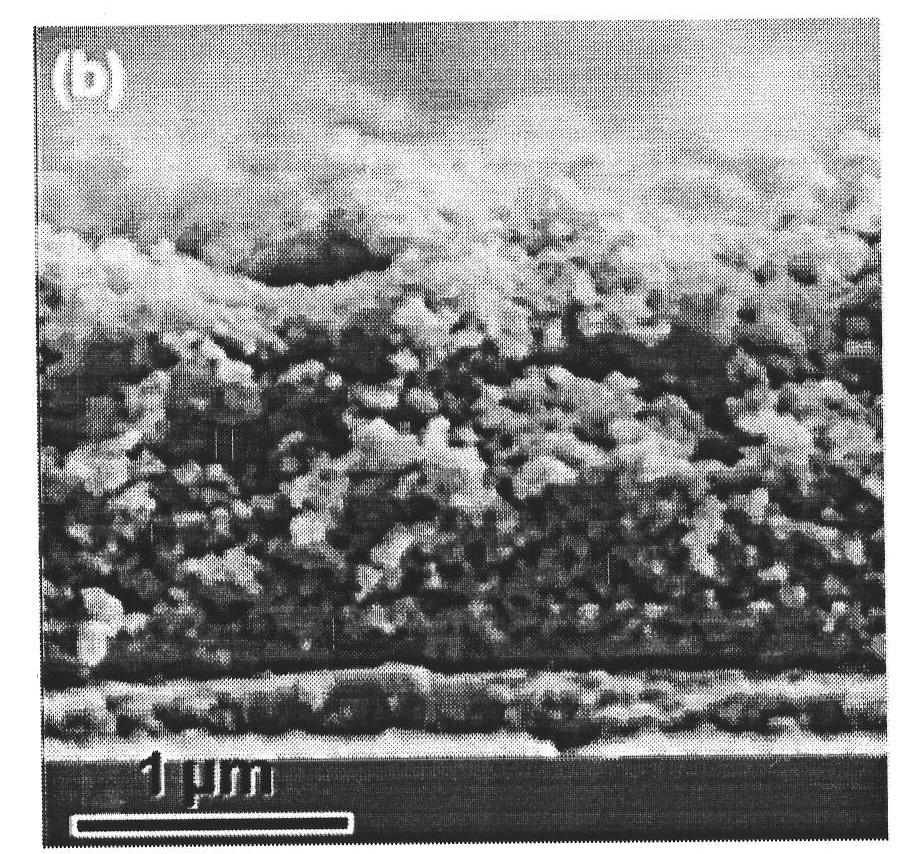

[0026] In the preparation method of the present invention, thiourea is excessive, and thiourea not only provides a sulfur source, but also coats the outside of CdS to prevent its further growth. Sodium dodecylbenzenesulfonate is a commonly used anionic surfactant, which can effectively form complexes with metal cations, thereby limiting the growth of particles. The formed CdS quantum dots will form a dendritic porous structure through the action of hydrogen bonds. Thiourea decomposes into NH under alkaline conditions 3 , CO 2 and S 2- , with the decomposition of thiourea, CO 2 Wait for the gas to come out from the inside, so that the anode material of this kind of quantum dot stacked porous structure is formed, see figure 1 with figure 2 , is a scanning electron micrograph of the sponge-like CdS quantum dot anode, figure 1 For top-down scanning electron microscope photographs, figure 2 SEM photograph of the side view. Ammonia water will promote the decomposition of t...

Embodiment 1

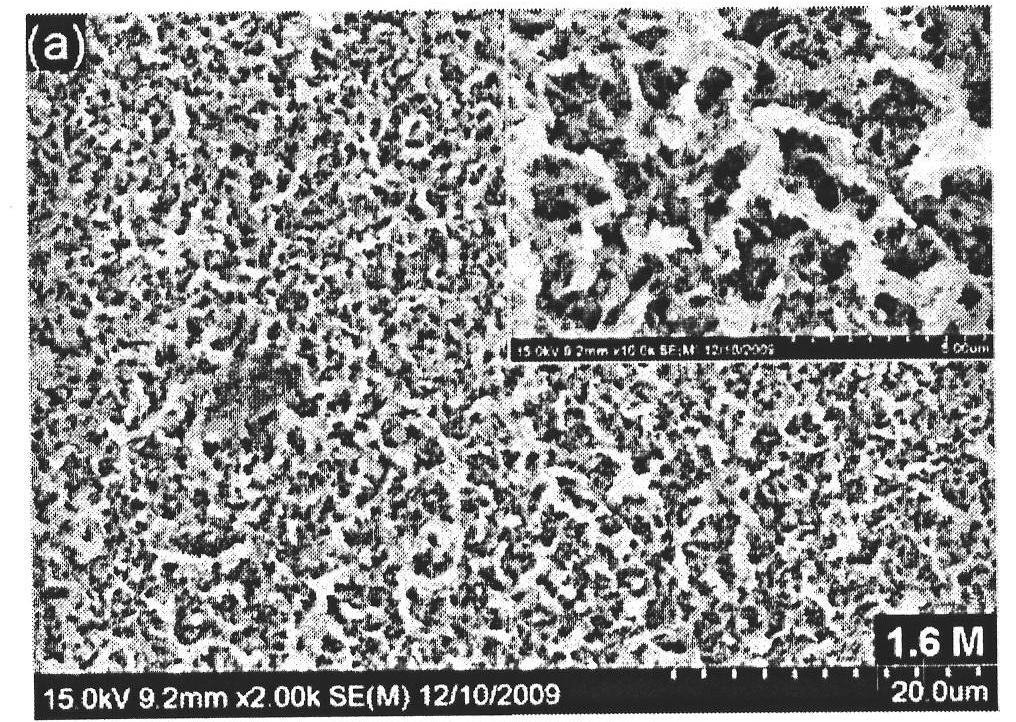

[0032] Preparation of a layer of TiO on FTO glass by the suspension coating method 2 The seed layer was then annealed at 500°C for 1 hour for later use. Prepare equal-volume aqueous solutions of 0.05mol / L cadmium acetate and 0.15mol / L thiourea, add in the aqueous solution of cadmium acetate according to the amount of ammonia concentration in the total reaction solution of 1.6mol / L and utilize ultrasonic waves to process it and mix it evenly. Then add the prepared thiourea aqueous solution, and at the same time add sodium dodecylbenzenesulfonate modifier and mix uniformly to form a reaction solution. There will be TiO 2 The FTO glass of the seed layer is placed in a reaction kettle filled with a reaction solution, and reacted at a reaction temperature of 120°C for 2 to 11 hours to prepare a spongy CdS quantum dot film layer, take out the prepared photoanode and test the obtained spongy CdS film Perform annealing treatment. Depend on image 3 It can be seen that a sponge-lik...

Embodiment 2

[0034] In the same reaction kettle as above, prepare an equal-volume aqueous solution of 0.05mol / L cadmium acetate and 0.15mol / L thiourea, and add the aqueous solution of cadmium acetate into the aqueous solution of cadmium acetate according to the amount of ammonia concentration in the total reaction solution of 1.8mol / L. Ultrasonic treatment, followed by adding an aqueous solution of thiourea, adding sodium dodecylbenzenesulfonate modifier and mixing uniformly as a reaction solution. The FTO glass is placed in a reaction kettle filled with a reaction solution, and reacted at a reaction temperature of 120°C for 2 to 11 hours to prepare a sponge-like CdS quantum dot film layer. Figure 4 It can be seen that a porous sponge-like structure is obtained, and the number and porosity of the pores are increasing, and the porosity is larger. After annealing, assemble the battery according to the above method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com