Tissue engineering scaffold material for repairing cartilage defects and preparation method thereof

A tissue engineering scaffold and soft tissue technology, applied in the preparation of the scaffold material, in the field of tissue engineering scaffold materials, can solve the influence of demineralized bone matrix on the ability to repair cartilage, the limited source of allogeneic human bone materials, and the inconsistency in repairing bone and cartilage. and other problems, to achieve the effect of low immunogenicity, good cell and biocompatibility, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

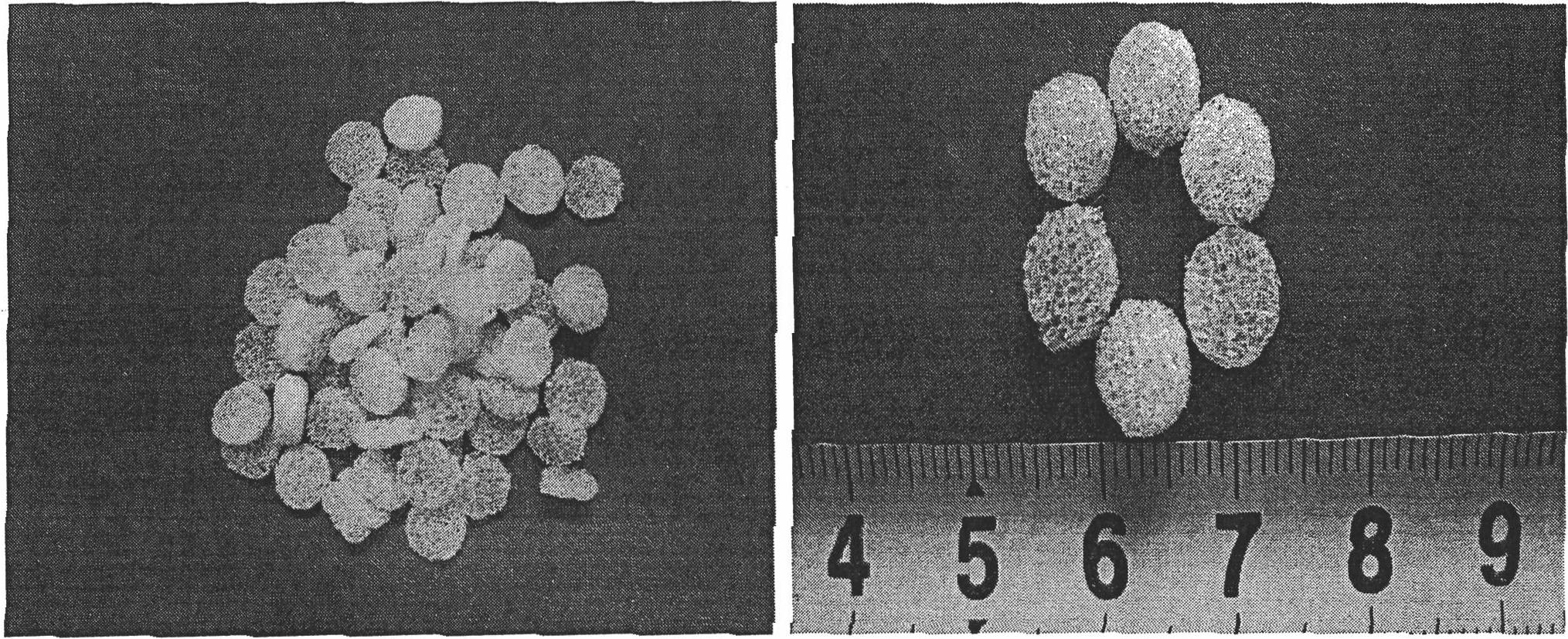

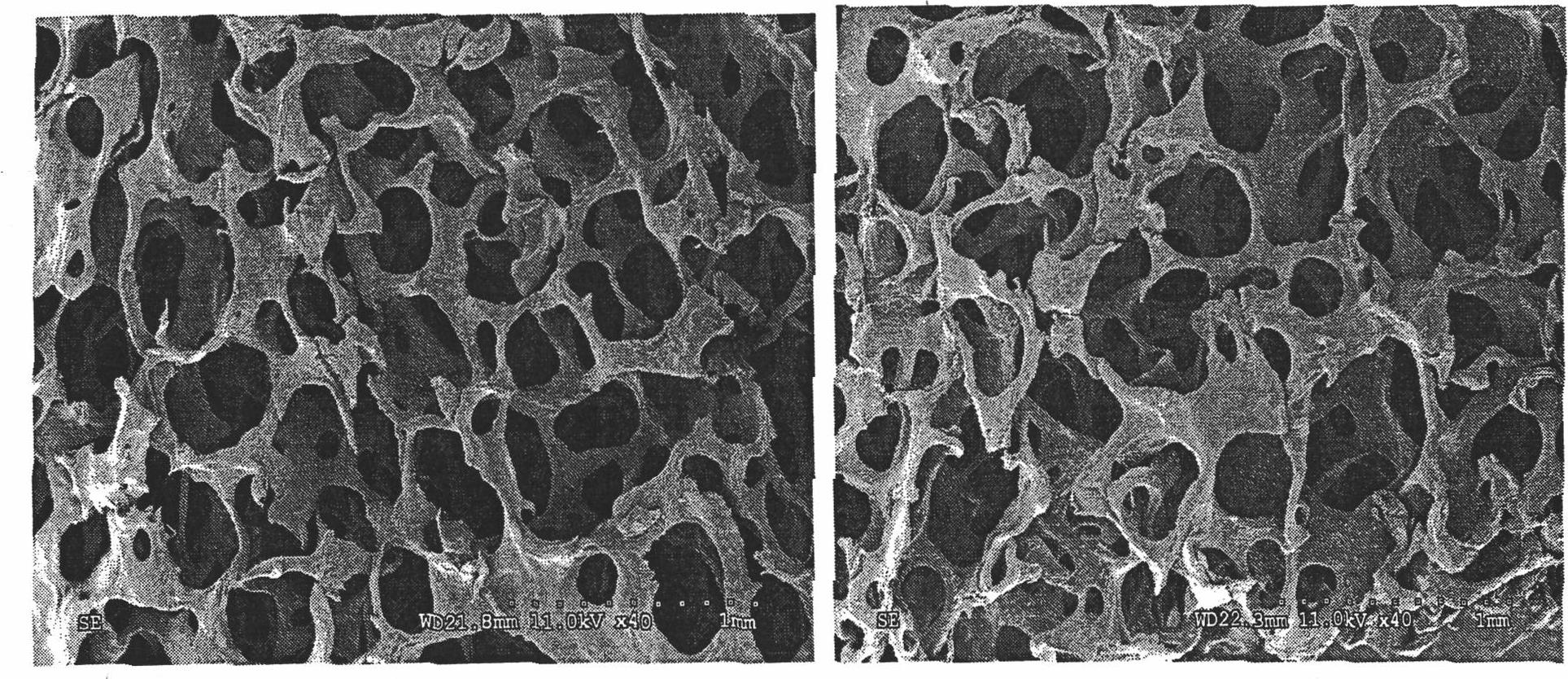

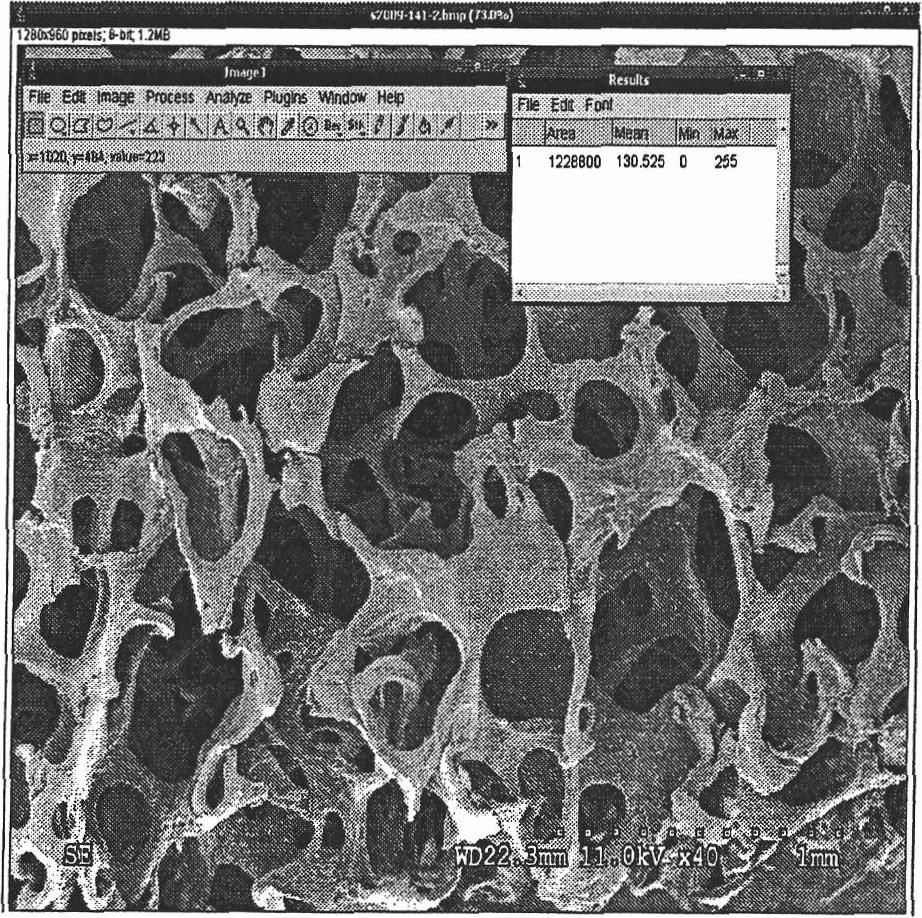

[0044] Experimental Example 1: Visual and SEM observation of DSBM

[0045] The appearance of DSBM scaffold material is white and sponge-like by naked eye. When it absorbs water, it has good elasticity when clamped with tweezers. It can squeeze out water and restore it. It has a certain toughness. It maintains its original shape and has a certain strength when dry. Porous structure, the surface pores are connected to the deep pores, and the pore sizes are different ( figure 1 ). Take 10 blocks of the prepared DSBM, fix with 2% glutaraldehyde at 4°C for 24 hours, rinse with 0.1 mol / L sodium cacodylate buffer, and fix with 1% osmium tetroxide for 2 hours. Rinse with 0.1mol / L sodium cacodylate buffer solution, dehydrate step by step with ethanol, store in isoamyl acetate overnight, dry at the critical point of carbon dioxide, adhere to the stage in a direction, spray gold in vacuum, and observe on the machine. The surface structure of DSBM was observed by scanning electron micro...

experiment example 2

[0048] Experimental example 2: In vitro co-cultivation of DSBM and BMSCs

[0049] According to the above method, 24 pieces of DSBM were taken from the three time periods of decalcification 6h, 12h and 24h respectively. After 24 hours of culture, the culture medium was sucked off with sterile absorbent cotton balls, and then placed in six 24-well culture plates. Put 1 piece of decalcified 6h DSBM material in holes A1, B1, C1, and D1 of each hole, put 1 piece of decalcified 12h DSBM material in holes A2, B2, C2, and D2, and put 1 piece of decalcified 12h DSBM material in holes A3, B3, C3, and D3. Calcium 24h DSBM material, will have a density of 5 x 10 6 40 μL of third-generation bone marrow mesenchymal stem cells (BMSCs) / mL were inoculated on the pre-wet material of 24-well culture plate, CO 2 Cultivate in the incubator for 4 hours, then add 1.2 mL of L-DMEM medium containing 15% newborn bovine serum to continue the culture, add the same medium as the background to wells A4, B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com