Aromatization method for producing light aromatics

A light aromatic hydrocarbon, aromatization technology, applied in chemical instruments and methods, bulk chemical production, organic chemistry, etc., can solve the problems of low conversion rate, poor combustion quality, waste of resources, etc., achieve high conversion rate, raw materials The effect of a wide range of sources and reduced dry gas yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

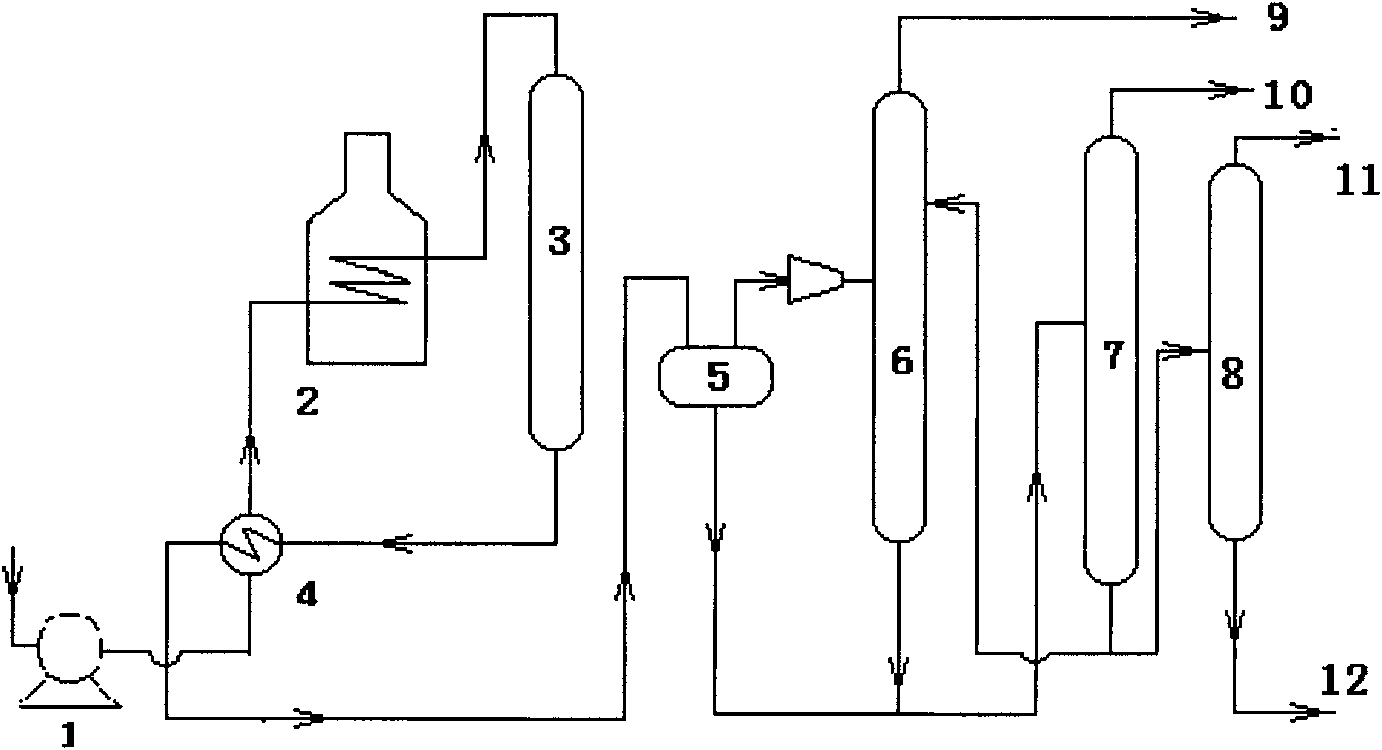

Method used

Image

Examples

preparation example Construction

[0033] The preferred preparation method of above-mentioned catalyst comprises the steps:

[0034] (1) After peptizing the precursor of the binder with acid, adding ZSM series zeolite and stirring to form a slurry, then dropping the slurry into an oil ammonia column to form a ball, drying and roasting the pellet to obtain a carrier,

[0035] (2) The carrier is impregnated with an impregnating solution prepared from a compound containing zinc, a compound containing rare earth elements and a compound containing group VA elements, then dried and calcined.

[0036] In the above method, step (1) is carrier preparation. First, the precursor of the binder is peptized with an acid. The acid can be nitric acid, hydrochloric acid, formic acid or acetic acid, preferably nitric acid, and the precursor of the binder is preferably pseudoboehmite. stone. When peptizing, the suitable ratio of the mass of the acid to the alumina contained in the pseudo-boehmite is 0.02-0.20:1, preferably 0.04-...

example 1

[0044] Preparation of the aromatization catalyst used in the present invention.

[0045] Get the pseudo-boehmite powder of 67.6 grams (Sasol company produces, Aluminum oxide content 74 mass %), under stirring condition, join concentration and be in the nitric acid aqueous solution of 300 milliliters of 1.1 mass %, stir 2 hours peptization, add the HZSM-5 zeolite powder that 55.0 grams of silicon oxide / alumina mol ratios are 60 (95% zeolite content), high-speed stirring for 3 hours. Drop the prepared slurry into an oily ammonia column containing 8% by mass of ammonia water, take out the wet ball formed in the oily ammonia column, dry at 60°C for 10 hours, and roast at 550°C for 3 hours to obtain 50% by mass of HZSM-5 zeolite and carrier pellets of 50% by mass alumina.

[0046] Get 50 grams of carrier pellets, use 60 grams of zinc nitrate containing 8.8 mass %, mixed rare earth chloride 1.3 mass % (wherein lanthanum oxide accounts for 31 mass %, cerium oxide 51 mass %, praseo...

example 2~4

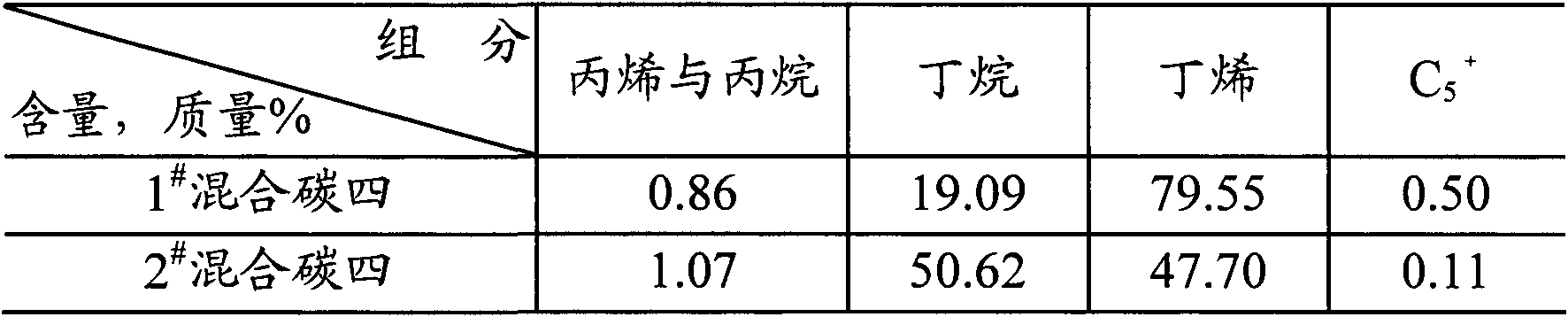

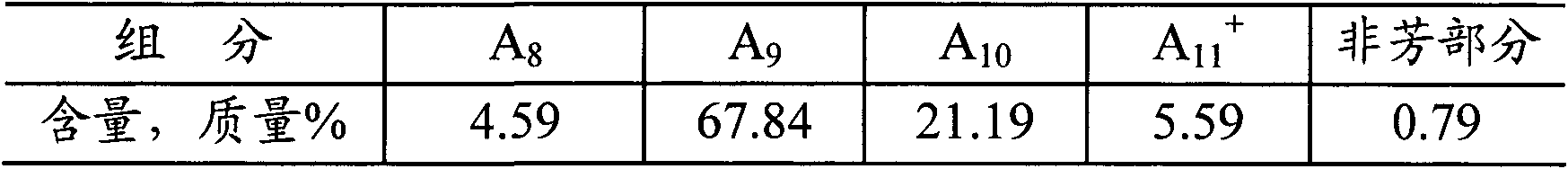

[0048] The following examples carry out the evaluation of the aromatization reaction of mixed carbon four and heavy aromatics, the mixed carbon four and C used in the reaction 9 + The compositions of heavy aromatics are shown in Table 1 and Table 2, respectively.

[0049] Will 1 # Hybrid carbon four and C 9 + Heavy aromatics are mixed and loaded into the raw material tank according to a certain mass ratio, and the raw material oil is sent into the reactor by a metering pump into a 20 ml fixed-bed continuous flow reactor filled with 10 grams of catalyst A for reaction. Feed quality space velocity 0.7 hours -1 Carry out aromatization reaction under the condition of , the obtained product distribution is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com