Dentin surface bionic hydroxyapatite coating preparation method

A biomimetic hydroxyapatite and dentin technology, used in dental preparations, dentistry, dentures, etc., can solve the problems of low mineralization, large differences, and low enamel organic components, and achieve orderly formation and high hardness. , the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

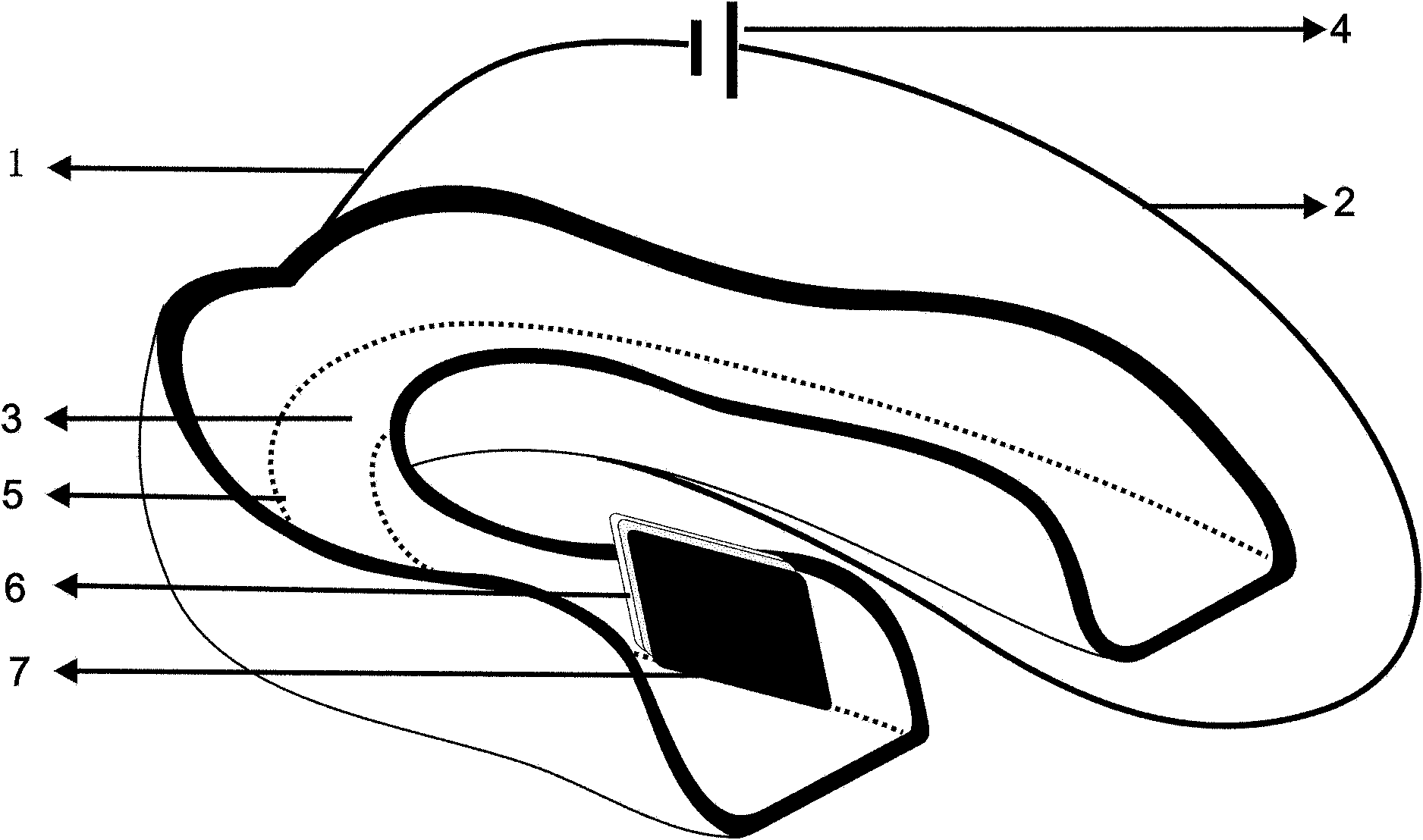

[0034] The preparation process of the biomimetic hydroxyapatite coating on the surface of dentin is as follows:

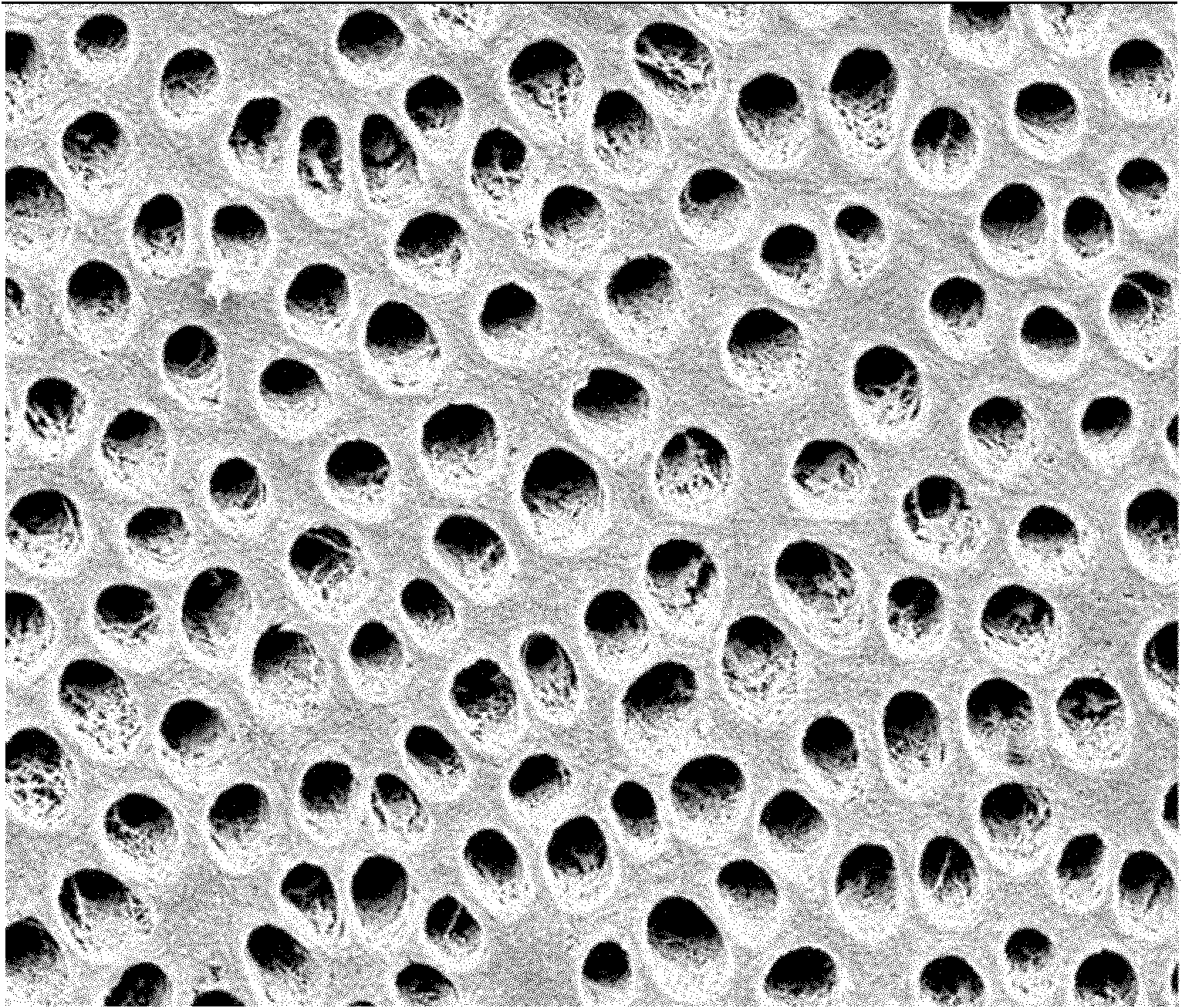

[0035] A. Put the flaky dentin sample in the root of the tooth into a phosphoric acid solution with a mass fraction of 37% for pretreatment, and treat it for 30 seconds. The scanning electron micrograph of the treated dentin surface is shown in figure 1 , and then put the dentin sample into a 10% sodium hypochlorite solution for deproteinization treatment, and the deproteinization treatment temperature is 20°C. B. Put the dentin sample treated in step A into the electrolyte gel for electrolysis. Dissolve 75.6 mg of calcium nitrate in distilled water to a concentration of 3.2 x 10 -3 M solution, and then 22mg of ammonium dihydrogen phosphate was dissolved in distilled water to prepare 1.96×10 -3 M solution, according to the calcium-phosphorus molar ratio of 1.67, the calcium-phosphorus-containing solution is mixed, the calcium ion mass concentration is 0.01%, and ...

Embodiment 2

[0038] The preparation process of the biomimetic hydroxyapatite coating on the surface of dentin in this embodiment is as follows:

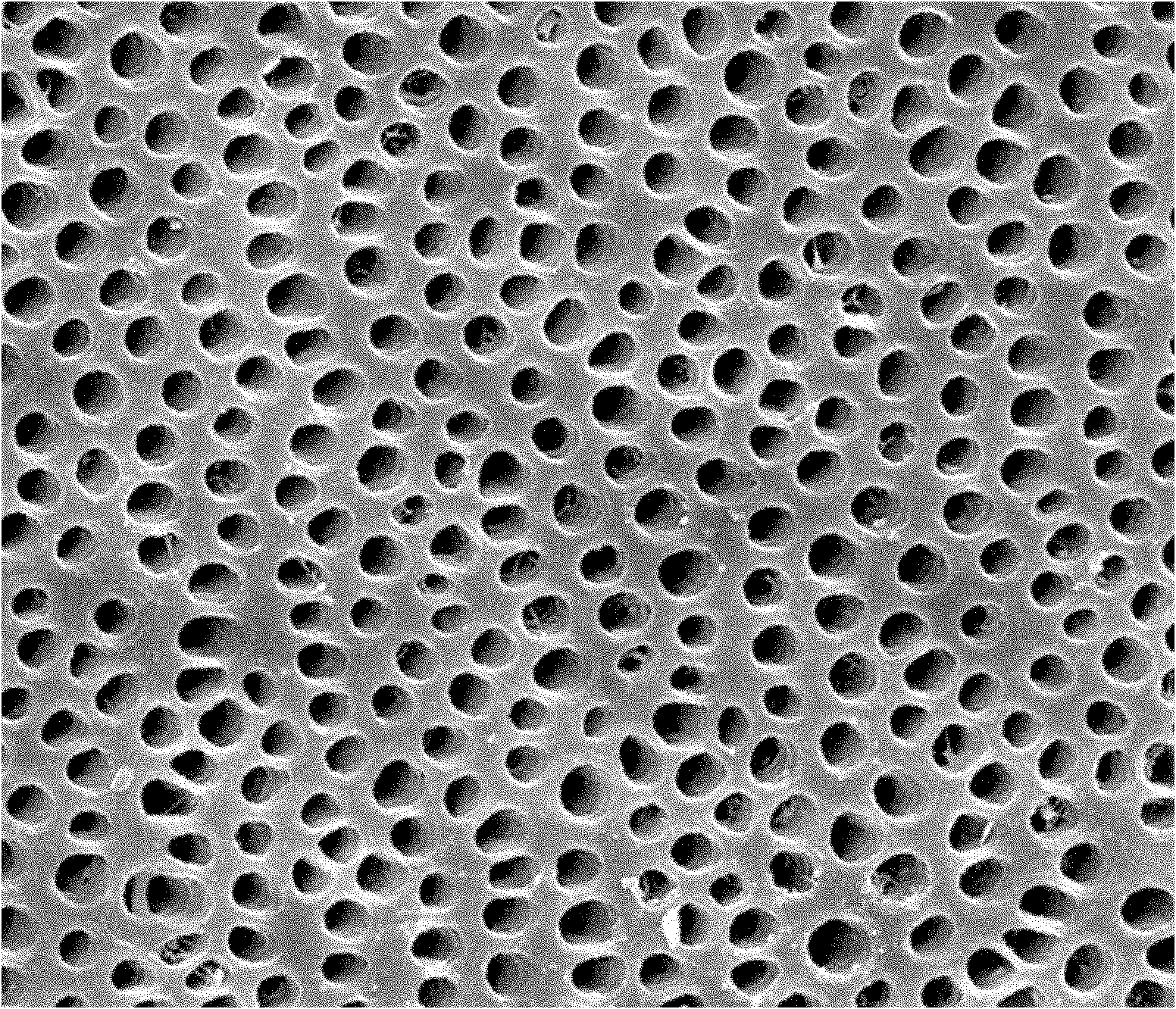

[0039] A. Put the flaky dentin sample in the crown part into 6% citric acid solution for pretreatment, and treat it for 2 minutes. The scanning electron microscope picture of the treated dentin surface is shown in figure 2 , and then put the dentin sample into a 10% sodium hypochlorite solution for deproteinization treatment, and the deproteinization treatment temperature is 30°C.

[0040] B. Put the dentin sample treated in step A into an electrochemical device for electrolysis, dissolve 133.2 mg of calcium chloride in distilled water, and prepare a concentration of 1.2×10 -3 M solution, and then 125.4 mg of potassium dihydrogen phosphate was dissolved in distilled water to prepare 0.72 × 10 -3 M solution, according to the calcium-phosphorus molar ratio of 1.67, the calcium-phosphorus-containing solution is mixed, the calcium ion mass concentr...

Embodiment 3

[0043] The preparation process of the biomimetic hydroxyapatite coating on the surface of dentin in this embodiment is as follows:

[0044] A, put the tooth crown flake dentin sample into the phosphoric acid solution of mass fraction 37% and carry out pretreatment, process 60s, then put the dentin sample into the mass fraction of 10% sodium hypochlorite solution, carry out deproteinization treatment, so The deproteinization treatment temperature is 30°C.

[0045] B. Put the dentin sample treated in step A into the electrolyte gel for electrolysis. Take 55.5 mg of calcium chloride and dissolve it in distilled water to prepare a concentration of 2.5×10 -2 mol / L solution, then take 40.8 mg of potassium dihydrogen phosphate and dissolve it in distilled water to prepare a concentration of 1.5×10 -2 mol / L solution, mix the calcium-phosphorus-containing solution according to the calcium-phosphorus molar ratio of 1.67, the calcium ion concentration is 0.3%, then add 0.07% porcine am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com