Hydrorefining catalyst for preparing fuel oil from coal tar, preparation method and application method thereof

A technology for hydrorefining and catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. problems, to achieve the effect of long service life, good operation stability and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

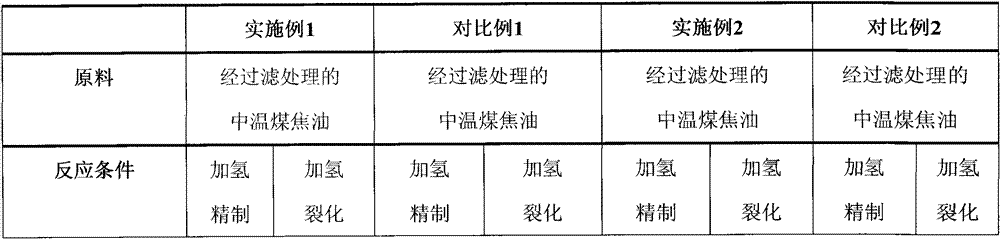

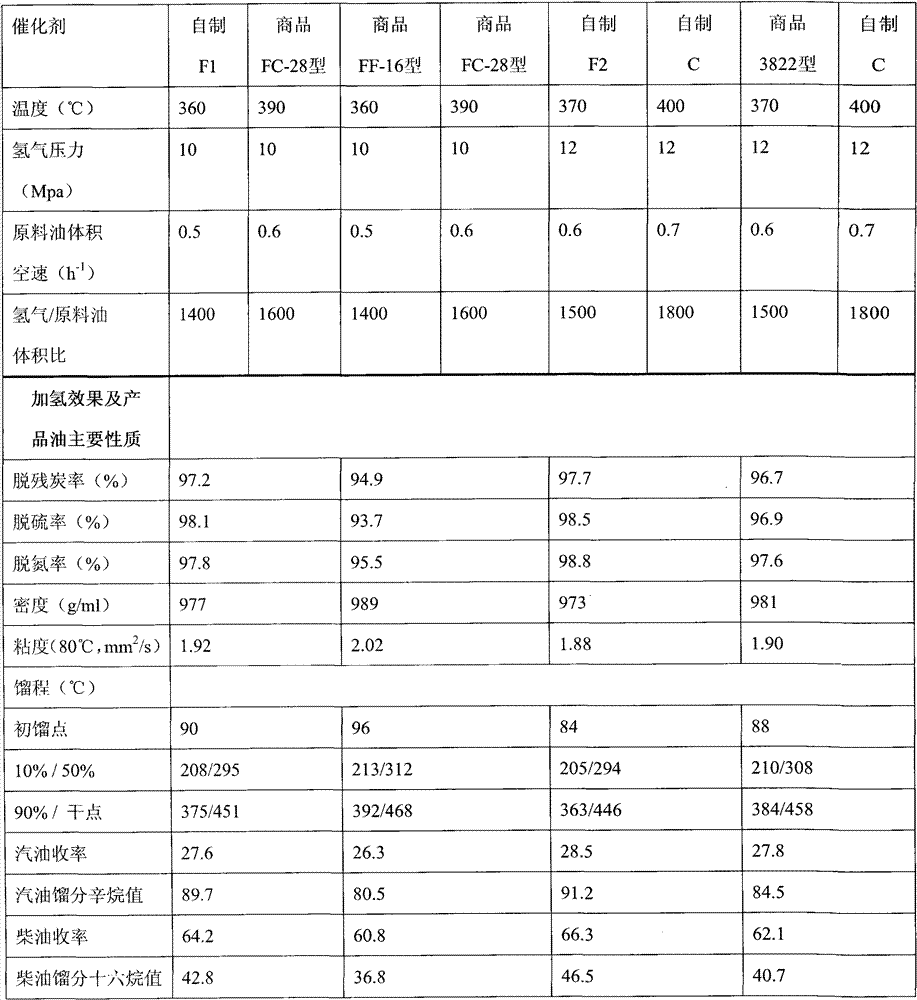

Embodiment 1

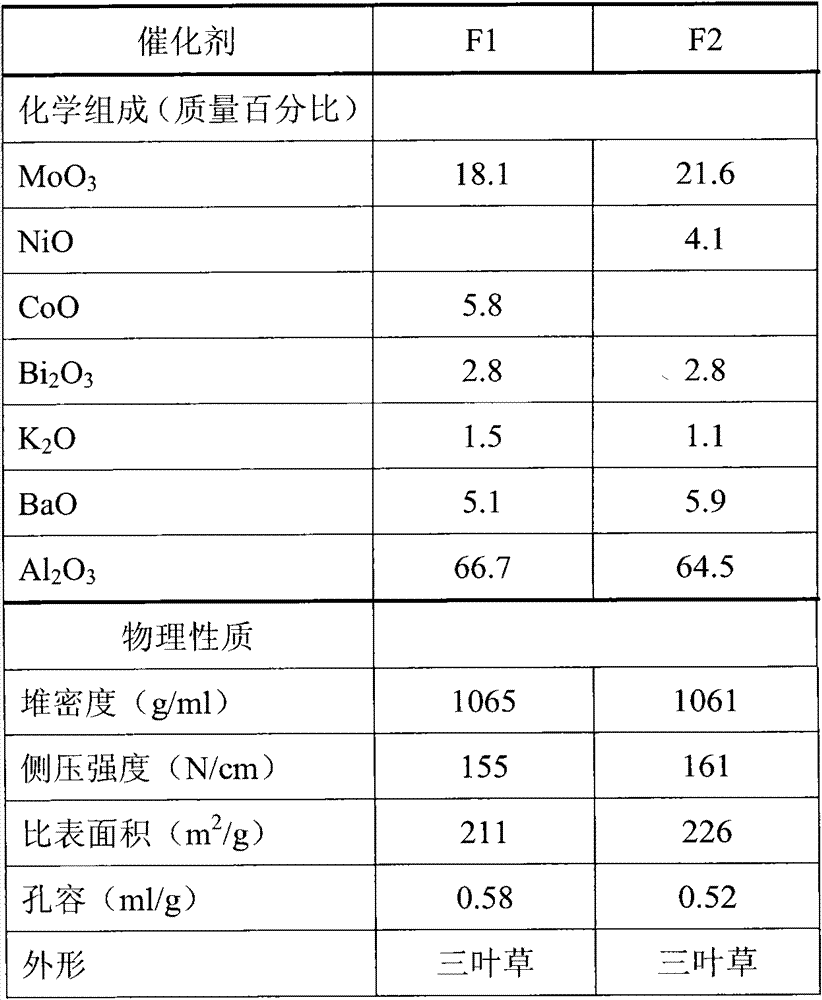

[0031] The preparation of hydrorefining catalyst F1 is as follows:

[0032] Commercially available SB aluminum hydroxide dry rubber powder 100g, add 8.4g barium nitrate fine powder, 1.1g nitric acid, 1.8g citric acid, reconcile into a wet rubber cake. The wet rubber cake is placed on a kneader, continuously sprinkled with 21.7g ammonium molybdate tetrahydrate fine powder, 22.9g cobalt nitrate hexahydrate fine powder, 1.2g cellulose, and knead evenly. Dry at 120°C for 14 hours and grind into fine powder.

[0033] Add 4g of safflower powder and a small amount of deionized water to the fine powder, and use a clover-shaped orifice plate to extrude on a screw extruder. The diameter of the extruded rod is 1.2mm, and the length is 3mm. The shaped strips were rinsed with acetic acid for 6 minutes. Dry at 110°C for 2 hours, and then bake at 490°C for 12 hours at a constant temperature of 490°C for 12 hours in an air atmosphere containing 35% molar concentration of water vapor with a...

Embodiment 2

[0040] The preparation of hydrorefining catalyst F2 is as follows:

[0041] Commercially available SB aluminum hydroxide dry rubber powder 100g, add 10g barium nitrate fine powder, 1g nitric acid, 1.2g acetic acid, 2g citric acid, reconcile into a wet rubber cake. The wet rubber cake is placed on a kneader, continuously sprinkled with 27.5g ammonium molybdate tetrahydrate fine powder, 15.9g nickel nitrate hexahydrate fine powder, 1g cellulose, and knead evenly. Dry at 120°C for 15 hours and grind into fine powder.

[0042] Add 3.2g safflower powder and a small amount of deionized water into the fine powder, and adopt clover-shaped orifice plate extrusion molding on the screw extruder. The extruded rod has a diameter of 1.5mm and a length of 3mm. The shaped strips were rinsed with acetic acid for 8 minutes. Dry at 110°C for 15 hours, and then bake at a constant temperature of 480°C for 12 hours in an air atmosphere containing 40% molar concentration of water vapor with an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com