Photocatalytic metal-molecular sieve composite catalyst and preparation method thereof

A composite catalyst and molecular sieve technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high photon energy and inability to directly use solar energy, and achieve low equipment requirements and low photon Low energy threshold and low solvent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Dissolve 0.1g of sodium metaaluminate in 20mL of deionized water, add 8mL of tetrapropylammonium hydroxide (TPAOH, 25wt%) and 7mL of tetrapropylammonium hydroxide (TPAOH, 25wt%) and 7mL of ethyl orthosilicate to the solution, and stir at room temperature for 12 hours until the solution is clear . The obtained solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, and placed in an oven at 180°C for crystallization in a static state. After 8 days, the reactor was taken out and naturally cooled to room temperature. The product obtained in the reactor was filtered, washed ultrasonically and then dried at 110°C. Put the dried white powder in a high-temperature tube furnace, slowly raise the temperature (2°C / min) to 600°C for 10 hours in an oxygen atmosphere, and then cool naturally to room temperature to obtain a sodium microporous molecular sieve (NaZSM-5 ).

[0040] Weigh 5g of the powder and disperse it in 200mL ammonium chloride sol...

Embodiment 2

[0046] Under argon protection, 1.0 g of metal-molecular sieve composite photocatalyst was evenly spread in a closed quartz reactor (reactor volume: 25 cm 3 ), then the reaction system was evacuated, and 1000 μmol of high-purity methane gas (>99.995%) was introduced to test the photocatalytic performance, and the catalytic product was collected online by gas chromatography for quantitative analysis. Such as Figure 4 Shown is the change curve of the amount of methane conversion with the light time at room temperature. It can be seen that the photocatalyst has a good catalytic methane conversion effect under different ultraviolet light source (high pressure mercury lamp or outdoor sunlight) irradiation conditions. For example, using a high-pressure mercury lamp as an irradiation source, each gram of catalyst per hour can catalyze 10.2 μmol of methane.

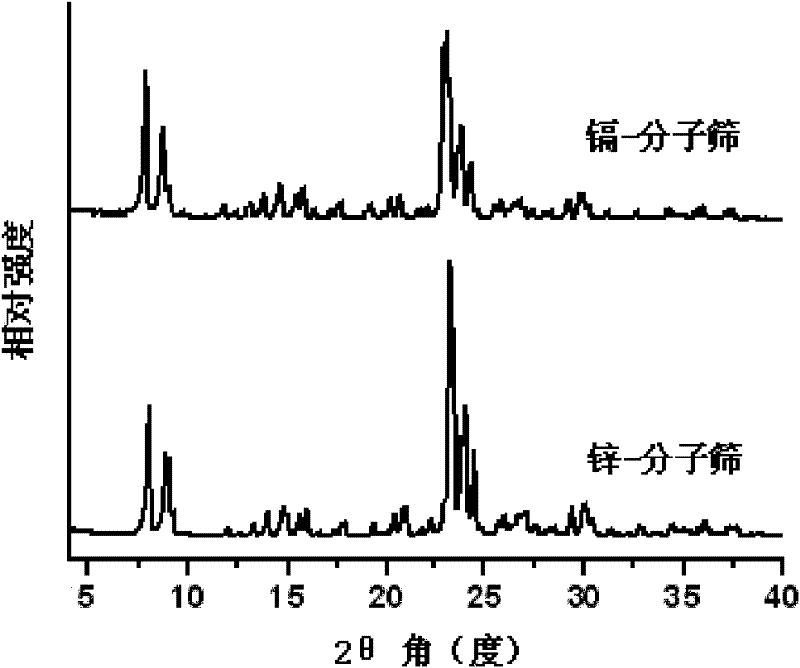

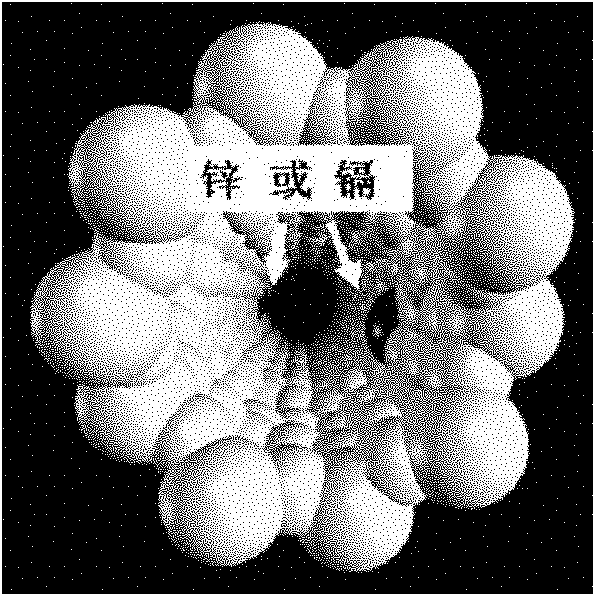

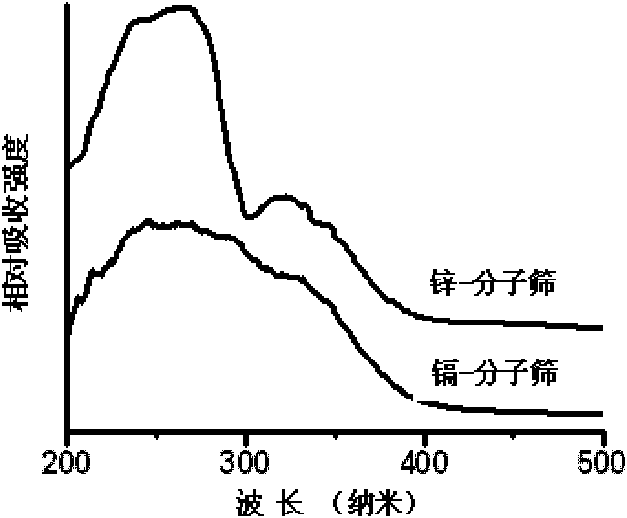

[0047] The molar ratio of the catalyst components prepared in this embodiment is Zn 0.7 AlSi 15 o 32 or CD 0.7 AlSi 15 o...

Embodiment 3

[0050] Under argon protection, 1.0 g of metal-molecular sieve composite photocatalyst was evenly spread in a closed quartz reactor (reactor volume: 25 cm 3 ), then the reaction system was evacuated, and 1000 μmol of high-purity oxygen (>99.99%) was introduced. After contacting at room temperature for 1 hour, remove excess oxygen, take 50 mg of catalyst in a hand box and seal it in a paramagnetic tube for magnetic measurement.

[0051] The molar ratio of the catalyst components prepared in this embodiment is Zn 0.7 AlSi 15 o 32 or CD 0.7 AlSi 15 o 32 , with a complete MFI molecular sieve configuration, after one hour of ultraviolet light irradiation, each gram of the catalyst can produce 3.7X 10 16 a monovalent metal zinc ion or cadmium ion.

[0052] Such as Figure 6 Shown are the electron spin resonance spectra of the catalyst before and after exposure to oxygen. It can be clearly seen from the spectra that after mutual contact, each oxygen molecule captures a single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com