Fluorine-containing polyurethane and preparation method thereof

A polyurethane and polymer technology, applied in polyurea/polyurethane coatings, coatings, paper coatings, etc., can solve problems such as poor controllability, environmental pollution, and loss of "three-proof" functions, and achieve excellent waterproof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

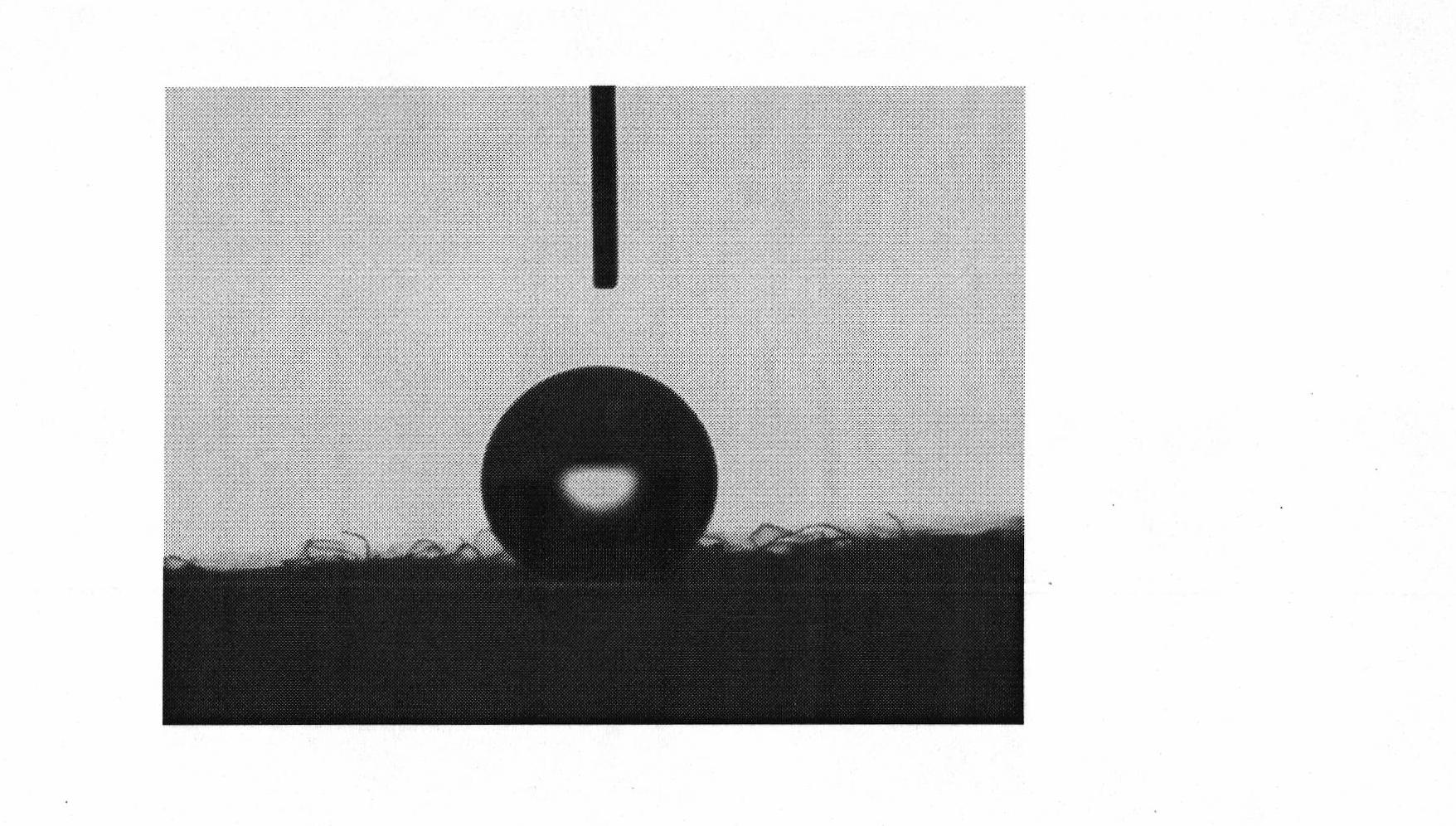

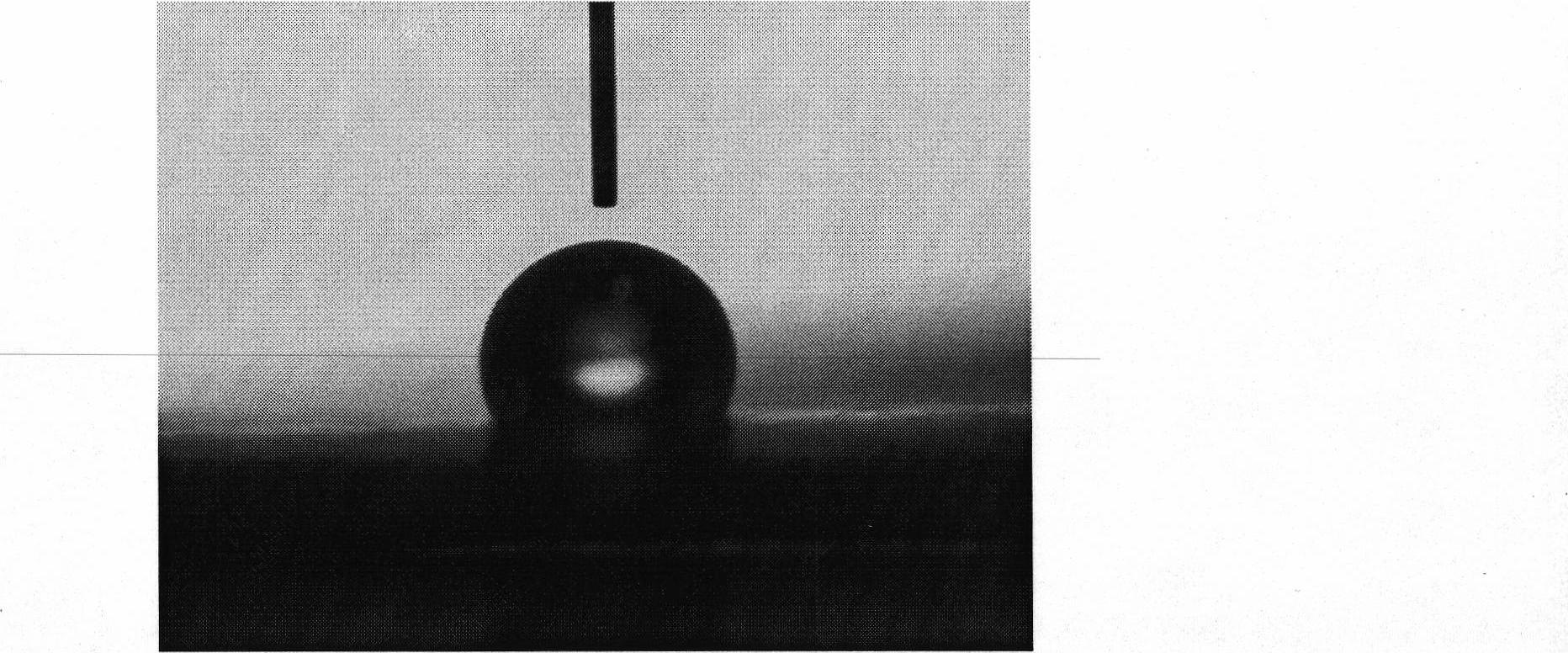

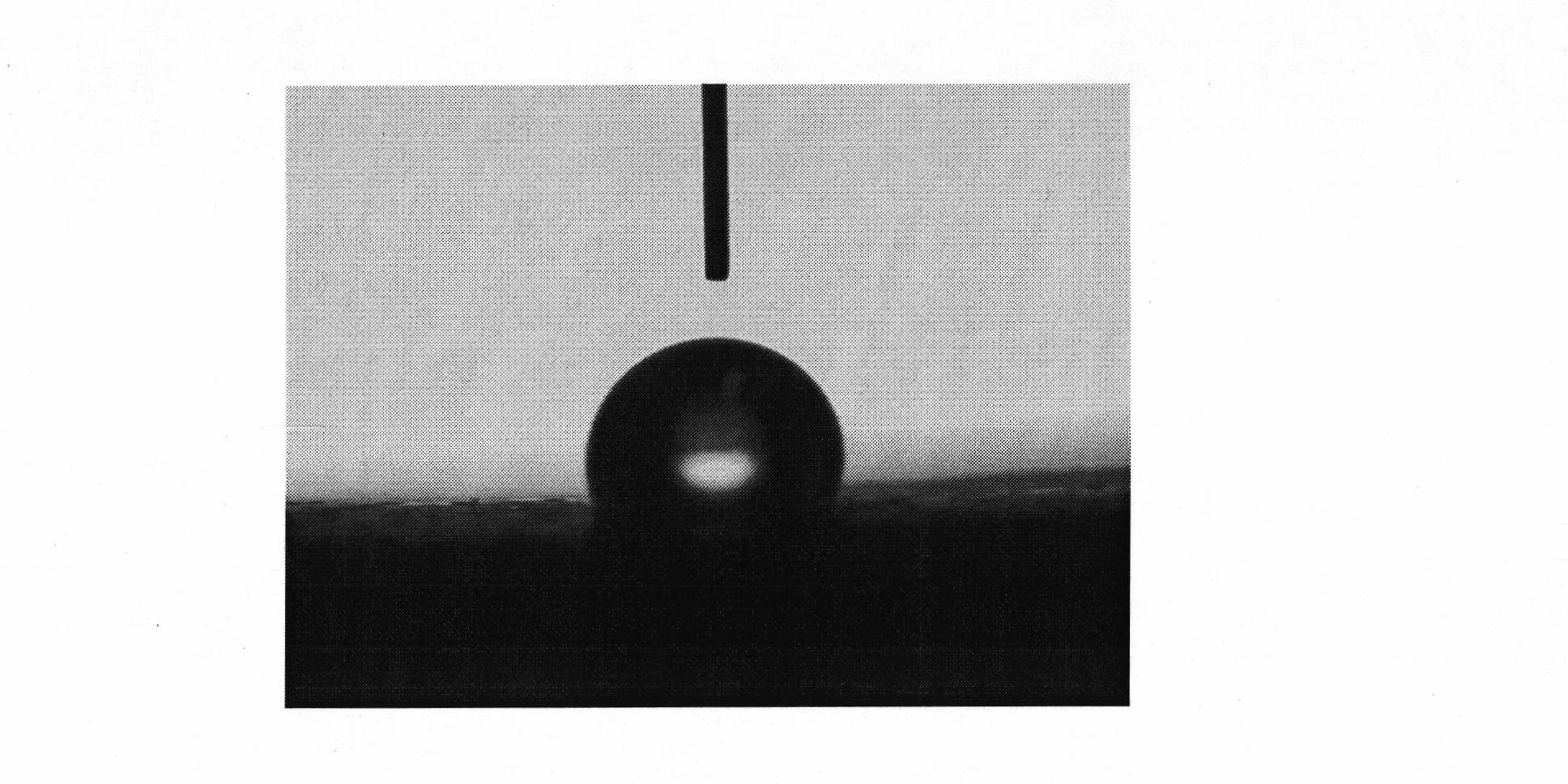

Image

Examples

Embodiment 1

[0059] Step 1: Add 105g of toluene diisocyanate TDI to a three-necked flask equipped with a thermometer, a constant pressure dropping funnel and a stirrer, protect it with nitrogen, and heat up to 80°C; Oxypropylene diol 210, after 1 hour of dripping, continue to react at 80°C for 1 hour, then add 12g of 1,4-butanediol chain extender to it, react at 70°C for 2 hours, stop the reaction after NCO reaches the theoretical value, and obtain isocyanate prepolymer.

[0060] Step 2: 46.46g of octafluoropentanol and 27.7g of 1,4-cyclohexane diisocyanate CHDI were dissolved in 173.1g of tetrahydrofuran to form a 30wt% solution, and the solution was added to a three-necked flask equipped with a thermometer and a stirrer In the process, nitrogen was passed to remove oxygen, and when the temperature rose to 80°C, 0.25g of triethylenediamine catalyst was added, and reacted at 80°C for 2 hours, and the temperature was lowered to 60°C after NCO reached the theoretical value. Afterwards, 20.1...

Embodiment 2

[0063] Step 1: Add 17.57g hexamethylene diisocyanate HDI, 41.79g polyethylene adipate diol PEA2000 and 59.36g acetone to a three-necked flask equipped with a thermometer and a stirrer, and stir to form 50wt% After heating up to 80°C, add 0.06g of stannous octoate catalyst, keep at 80°C for 3 hours, and stop the reaction after the NCO reaches the theoretical value to obtain an isocyanate prepolymer.

[0064] Step 2: 30g perfluoroalkyl ethyl heptanol and 19.97g toluene diisocyanate TDI are dissolved in 49.97g butyl acetate to form a 50wt% solution, and this solution is added to a three-necked flask equipped with a thermometer and agitator , Nitrogen to remove oxygen, when the temperature rises to 70°C, add 0.03g stannous octoate catalyst, and react at 70°C for 0.6h, when NCO reaches the theoretical value, lower the temperature to 60°C. Afterwards, 7.92 g of glycerin and 7.92 g of butyl acetate were added and reacted at 60° C. for 1 hour to obtain a butyl acetate solution of a fl...

Embodiment 3

[0067] Step 1: Add 20.77g of polyoxypropylene diol 220 to a three-necked flask equipped with a thermometer and a condenser, vacuum dehydrate at 120°C for 4 hours, and add 36g of diphenylmethane diisocyanate MDI, 0.65g of ethylene glycol and 0.01g of dibutyltin dilaurate were kept at 50°C for 3 hours. After the NCO reached the theoretical value, the reaction was terminated to obtain an isocyanate prepolymer.

[0068] Step 2: 81.67g perfluoroalkyl ethyl decanol and 44.05g diphenylmethane diisocyanate MDI are dissolved in 53.88gN, in N-dimethylformamide, form a 70wt% solution, this solution is added to the In the three-necked flask with thermometer and stirrer, when the temperature rises to 60°C, add 0.2g of cyclohexylmethyl tertiary amine catalyst, and react at 60°C for 2h, and add 14.24g of triethanolamine and 6.1g of NCO after the NCO reaches the theoretical value. , N-dimethylformamide, react at 60°C for 1h to obtain N,N-dimethylformamide solution of fluoropolymer chain exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com