Preparation method of composite photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate

A nano-titanium dioxide and photocatalyst technology is applied in the field of environmental pollution control, which can solve the problems of large particle size of zinc titanate powder, uneven distribution of components, and large environmental pollution, and achieves good dispersibility, short process flow, and equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

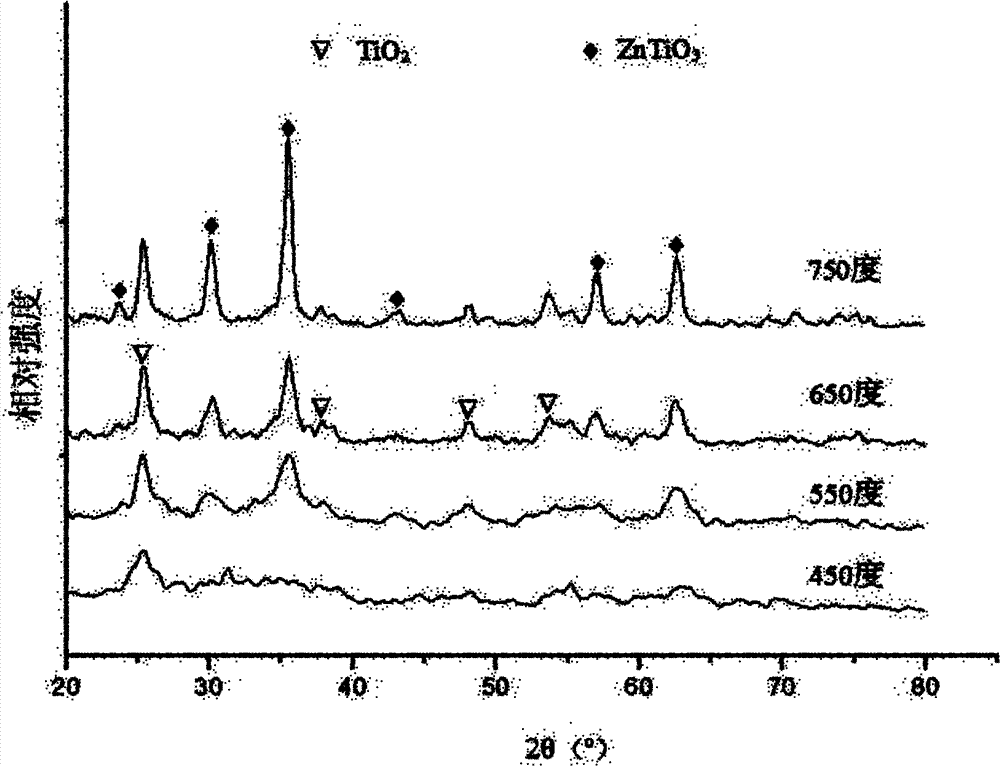

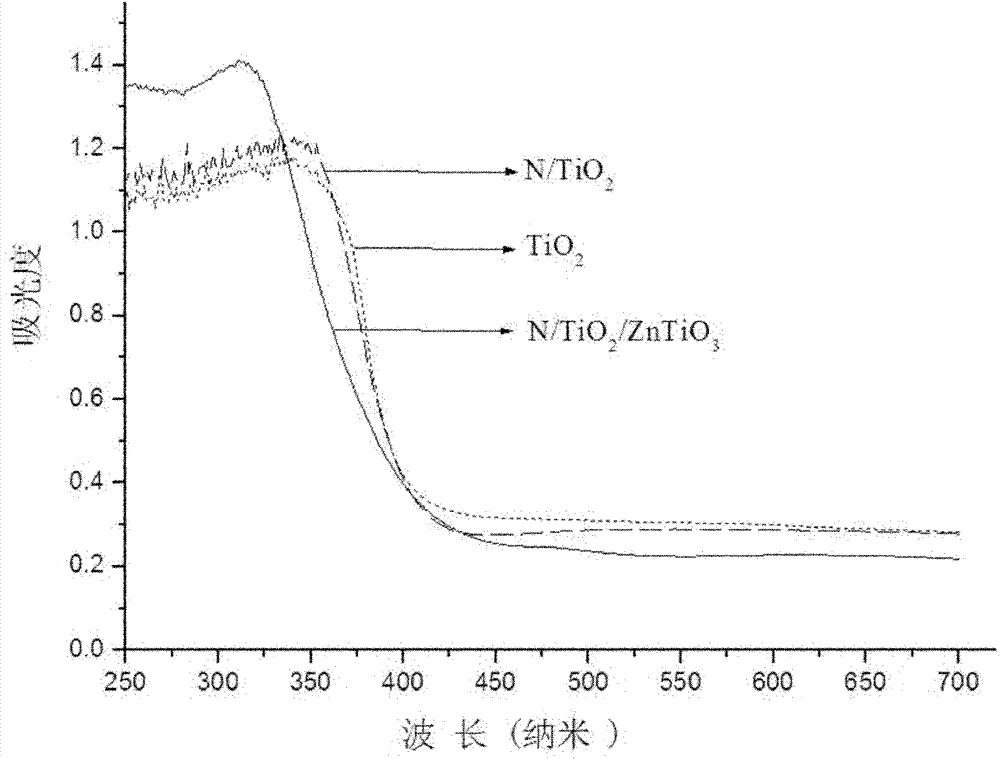

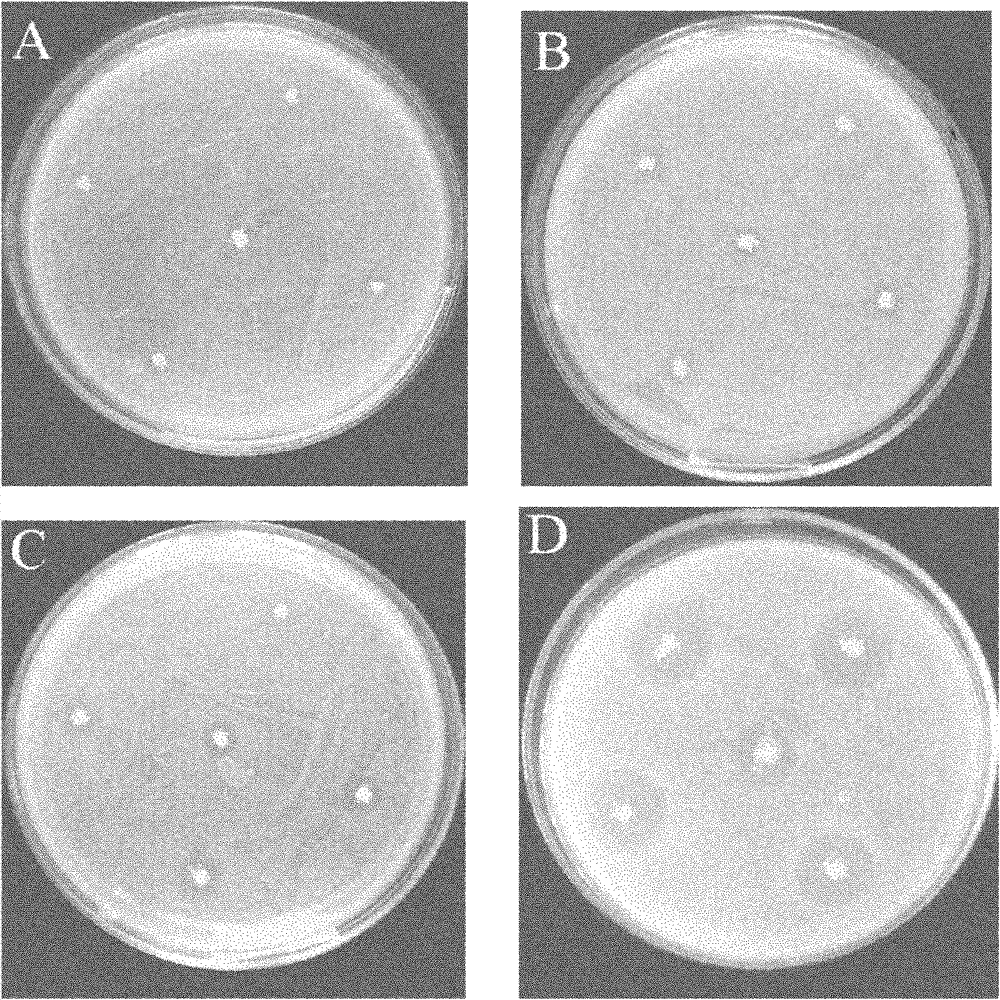

Embodiment 1

[0039]In the soluble salt of titanium, urea is used as precipitant and doped nitrogen source, and zinc salt is used as composite zinc source, and nitrogen and composite zinc oxide are doped in the preparation of titanium dioxide by uniform precipitation method. To 0.1-0.5mol L -1 In the titanium sulfate solution, according to the ratio of the amount of substances, it is titanium sulfate: urea: zinc sulfate = 1: 10: 0.5 to prepare 150 mL of mixed solution, place it in a three-necked flask with a reflux cooling device, stir evenly, and add 20 mg Sodium dodecylbenzenesulfonate, a surfactant, is heated in a water bath to 60°C, urea decomposes to form a titanium dioxide precursor, and the temperature is kept constant for 0.5h. Then heat up to 90-100°C to completely decompose urea, slowly increase the pH of the solution, carry out nitrogen doping and semiconductor recombination, continue to stir and keep warm for 3-6h, and then use 0.5mol L -1 Ammonia slowly adjust the pH of the so...

Embodiment 2

[0046] In order to test the influence of different types of zinc sources on the properties of composite powders, except for the different types of zinc sources, the fixed reaction temperature is 95°C, the pH value of the solution is 7, the calcination temperature is 650°C, and other reaction conditions are the same as those in the examples. 1 with the same conditions. Figure 5 , 6 Indicates the comparison of the performance of samples prepared by adding different types of zinc sources in the process of precursor formation of titanium dioxide in the catalytic degradation of 10 mg / L methyl orange solution under 15 watt fluorescent lamp and 8 watt ultraviolet light respectively. Nitrogen-doped titanium dioxide / zinc titanate semiconductor compound Body (1), (2), (3), and (4) respectively represent that the composite zinc source is analytically pure zinc oxide, zinc nitrate, zinc chloride, and zinc sulfate. The results show that the photocatalytic rate of semiconductor composite ...

Embodiment 3

[0048] In order to test the influence of the concentration of the mixed solution on the performance of the semiconductor complex, the concentration of titanium sulfate, urea, and zinc salt solution was changed, the reaction temperature of the fixed reaction water bath was 95°C, the pH of the solution was adjusted to 7, the calcination temperature was fixed at 650°C, and other experimental conditions According to embodiment 1 method. The results show that when the concentration of titanium sulfate is 0.1-1.0mol L -1 , the concentration of urea is 0.28-3.0mol L -1 , the concentration of zinc salt solution is 0.01-0.5mol L -1 , the anatase titanium dioxide and zinc titanate semiconductor composite powder with small particle size and uniform shape was obtained, and had good antibacterial and photocatalytic degradation activities. The best experimental conditions are titanium sulfate concentration 0.1-0.5mol L -1 , the concentration of urea is 0.28-1.4mol L -1 , the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com