Method for simultaneously removing organic pollutants and ammonia in waste water and reactor

A technology for organic pollutants and reactors, applied in water pollutants, chemical instruments and methods, multi-stage water/sewage treatment, etc. The effect of time, wide range of oxygen sources and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

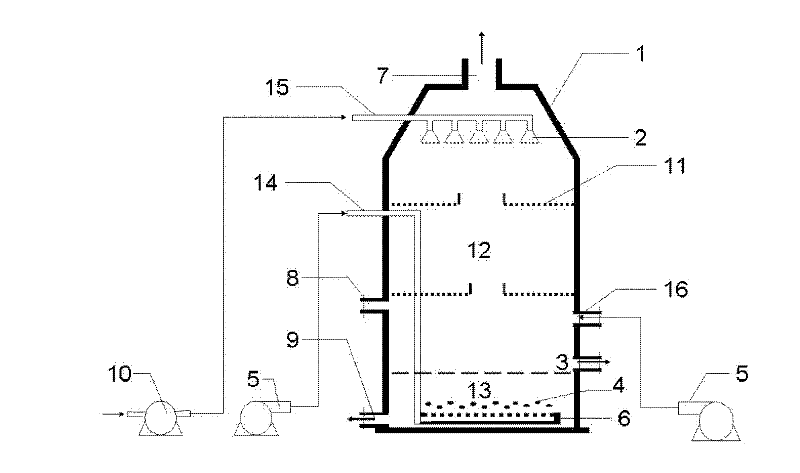

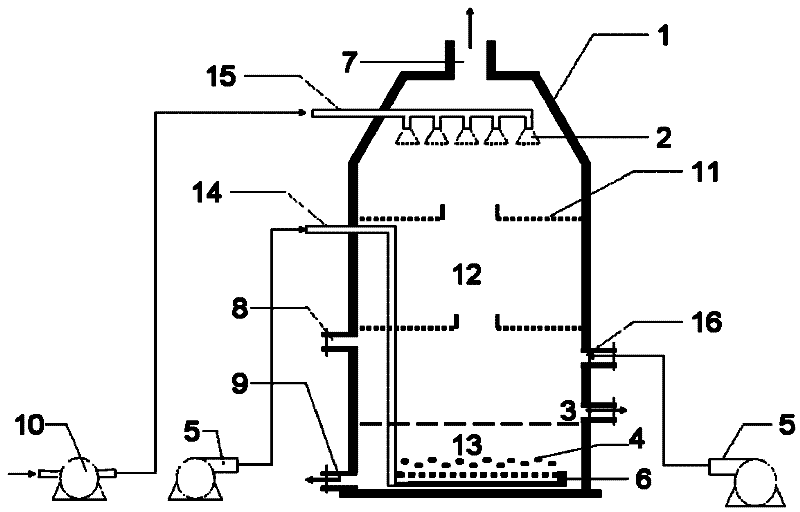

[0023] Treatment of landfill leachate in a reactor that simultaneously removes organic pollutants and ammonia from wastewater

[0024] Take 30L of landfill leachate, adjust the pH to 12, COD is 1835mg / L, NH 3 -N is 1367 mg / L. The wastewater is sprayed into the blowing and removing ammonia chamber through the atomizing nozzle, and at the same time, air is introduced into the catalytic oxidation tank to make the dissolved oxygen concentration in the water 0.5mg / L, and 24g of iron sulfate is added. After 120 minutes, the NH of the wastewater 3 -N is 372mg / L, NH 3 The removal rate of -N is about 73%, the COD of wastewater is 632mg / L, and the removal rate of organic pollutants is about 65%.

Embodiment 2

[0026] Treatment of landfill leachate in a reactor that simultaneously removes organic pollutants and ammonia from wastewater

[0027] Take 30L of landfill leachate, adjust the pH to 11, COD is 1987mg / L, NH 3 -N is 2691 mg / L. The wastewater is sprayed into the blowing and removing ammonia chamber through the atomizing nozzle, and at the same time, air is introduced into the catalytic oxidation tank to make the dissolved oxygen concentration in the water 1.0mg / L, add 20g of ferric oxide, and the NH of the wastewater 3 -N is 989mg / L, NH 3 The removal rate of -N is about 63%. After 120 minutes, the COD of wastewater is 598mg / L, and the removal rate of organic pollutants is about 70%.

Embodiment 3

[0029] Treatment of wastewater in a reactor that simultaneously removes organic pollutants and ammonia from wastewater

[0030] Take 30L of waste water, pH=12, COD is 1530mg / L, NH 3 -N is 1269 mg / L. The wastewater is sprayed into the blowing and removing ammonia chamber through the atomizing nozzle, and at the same time, air is introduced into the catalytic oxidation tank to make the dissolved oxygen concentration in the water 1.2mg / L, and 18g of iron sulfate is added. After 120 minutes, the NH of the wastewater 3 -N is 486mg / L, NH 3 The removal rate of -N is about 62%, the COD of wastewater is 543mg / L, and the removal rate of organic pollutants is about 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com