Preparation method of nanofiber separation composite membrane with gluing transition layer

A technology of nanofibers and transition layers, applied in the field of preparation of nanofiber separation composite membranes, can solve the problems of infiltration into the pores of basement membranes, difficulty in application and promotion, and decrease in membrane water flux, achieving low cost, convenience and accuracy The effect of hydrophilicity and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

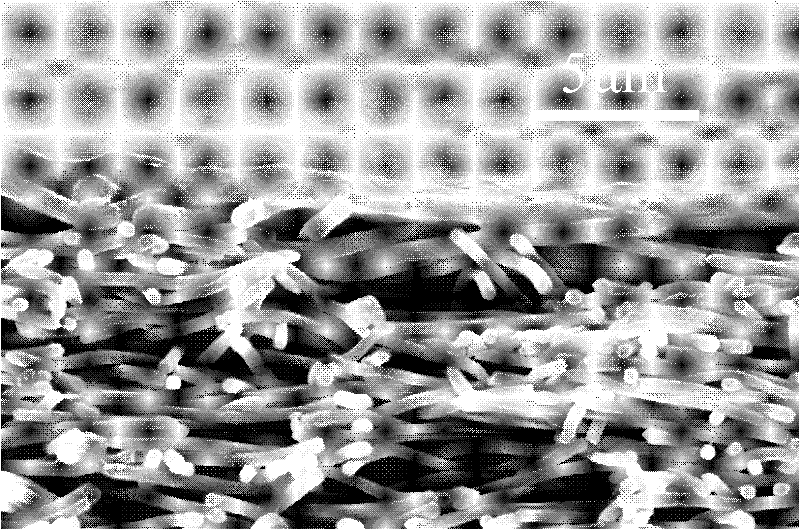

[0028] (1) Dissolve 30g of polyethersulfone in 70g of N,N-dimethylacetamide to obtain a transparent and uniform electrospinning solution; add the spinning stock solution into the container, and control the extrusion by a micro-injection pump. High-voltage positive electrode, electrospinning parameters controlled at voltage 24kv, nozzle aperture 1.8mm, solution flow rate 16μl / min, ambient temperature 25°C, air relative humidity 35%, electrospinning, the obtained polyethersulfone electrospun nanofibers The average diameter is 435nm, the deposition thickness is 45μm, and the porosity is 91%;

[0029] (2) Dissolve 15g of polyvinyl alcohol in 1L of water, and stir until the solution is clear and transparent;

[0030] (3) Soak the polyethersulfone nanofiber membrane in the polyvinyl alcohol solution for 24 hours, apply a chitosan acetic acid solution with a concentration of 5 wt% on the surface of the modified nanofiber membrane after appropriate treatment, and dry in the shade for ...

Embodiment 2

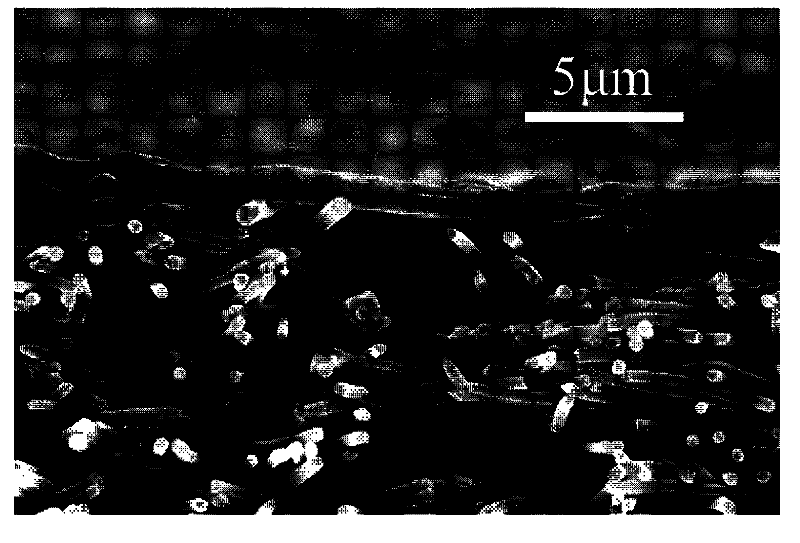

[0033] (1) Dissolve 20g of polysulfone in 80g of N,N-dimethylformamide to obtain a transparent and uniform electrospinning solution; add the spinning stock solution into the container, and control the extrusion by a micro-injection pump, and connect the nozzle to high pressure For the positive electrode, the electrospinning parameters are controlled at a voltage of 20kv, the nozzle aperture is 1.8mm, the solution flow rate is 20μl / min, the ambient temperature is 25°C, and the relative air humidity is 50%. Electrospinning is performed, and the average diameter of the obtained polysulfone electrospun nanofibers is is 850nm, the deposition thickness is 50μm, and the porosity is 87%;

[0034] (2) Select disodium hydrogen phosphate-potassium dihydrogen phosphate with a pH value of 4 as a buffer solution, and dissolve 1 g of dopamine in 1L disodium hydrogen phosphate-potassium dihydrogen phosphate buffer solution;

[0035] (3) Immerse the polysulfone nanofibrous membrane in the dopa...

Embodiment 3

[0038] (1) Dissolve 15g of polyacrylonitrile in 85g of N,N-dimethylformamide to obtain a transparent and uniform electrospinning solution; add the spinning stock solution into the container, and extrude it under the control of a micro-injection pump. High-voltage positive electrode, electrospinning parameters controlled at voltage 18kv, nozzle aperture 1.8mm, solution flow rate 30μl / min, ambient temperature 25°C, air relative humidity 45%, electrospinning, the obtained polyacrylonitrile electrospun nanofibers The average diameter is 600nm, the deposition thickness is 60μm, and the porosity is 93%;

[0039] (2) Tris-hydrochloric acid with a pH value of 9.0 was selected as a buffer solution, and 2 g of dopamine hydrochloride was dissolved in 1 L of tris-hydrochloric acid buffer solution to prepare a dopamine hydrochloride solution.

[0040] (3) Prepare a dopamine hydrochloride solution with a concentration of 2.0 g / L. Soak the polyacrylonitrile-based film in the dopamine soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com