Method for recycling phosphorus from urban sludge anaerobic digestive fluid by utilizing dolomite

A technology of anaerobic digestion and municipal sludge, applied in the field of recovering phosphorus resources, can solve the problems of high cost of chemicals, low recovery rate of phosphorus, low phosphorus content of recovered products, etc., and achieve the effect of reducing the cost of chemicals and enriching reserves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

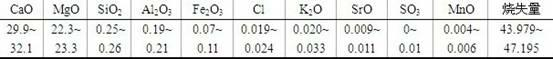

[0045] The dolomite is ground and screened, and the dolomite particles with a mesh number ranging from 50 to 80 mesh are selected for use.

[0046] After the municipal sludge is digested at constant temperature and anaerobic, the anaerobic digestion liquid is taken, and the initial orthophosphorus and total phosphorus concentrations are measured to be 73.11mg / L and 75.12mg / L respectively, and the initial calcium ion and magnesium ion concentrations are respectively 229.60mg / L and 45.55mg / L, the initial carbonate concentration is CaCO 3 Calculated as 1021.62mg / L. The above-mentioned municipal sludge anaerobic digestion solution is filtered through a medium-speed qualitative filter paper to remove part of suspended solids and organic matter, and the filtered anaerobic digestion solution is obtained.

[0047] Take 24.0g of dolomite particles of 50-80 mesh and add it to 300ml filtered anaerobic digestion solution, then acidify the dolomite-anaerobic digestion solution system with...

Embodiment 2

[0054] The filtered anaerobic digestate prepared in Example 1 was used.

[0055]Take 24.0g of 30-50 mesh dolomite particles and add it to 300ml filtered anaerobic digestion solution, then acidify the dolomite-anaerobic digestion solution system with a concentration of 2.0mol / L hydrochloric acid solution, adjust and control the pH to 4.0~ 4.5, stir at 500-600rpm, dissolve for 8.0h, and filter through a mixed fiber filter membrane with a pore size of 0.45 microns to obtain an eluate rich in calcium and magnesium for the first step of phosphorus recovery. The measured concentrations of calcium ions and magnesium ions in the eluate were 1589.35 mg / L and 723.17 mg / L, respectively, and the concentration of orthophosphorus was 70.13 mg / L.

[0056] Take the eluate, adjust the pH to 9.0 with 1.0 mol / L NaOH solution, react for 30 minutes, and filter the reaction system with a mixed fiber filter membrane with a pore size of 0.45 microns to obtain the precipitate and supernatant. It was ...

Embodiment 3

[0062] After the municipal sludge is digested at constant temperature and anaerobic, the anaerobic digestion liquid is taken, and the initial concentration of orthophosphorus and total phosphorus are measured to be 91.16mg / L and 92.16mg / L respectively, and the initial concentration of calcium ion and magnesium ion are respectively 236.00mg / L and 56.93mg / L, the initial carbonate concentration is CaCO 3 Calculated as 1392.48mg / L. Using the same filtration method and conditions as in Example 1, the filtered anaerobic digestion solution was obtained.

[0063] Take 24.0g of dolomite particles ranging from 20 to 30 meshes and add it to 300ml of filtered anaerobic digestion solution, then acidify the dolomite-anaerobic digestion solution system with a concentration of 2.5mol / L hydrochloric acid solution, adjust and control The pH is 4.0-4.5, stirred at 500-600 rpm, dissolved for 8.0 hours, and filtered through a mixed fiber filter membrane with a pore size of 0.45 microns to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com