Production process of bacillus psychrosaccharolyticus extracellular polysaccharide and application thereof

A technology of bacillus and exopolysaccharide, applied in the field of biology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

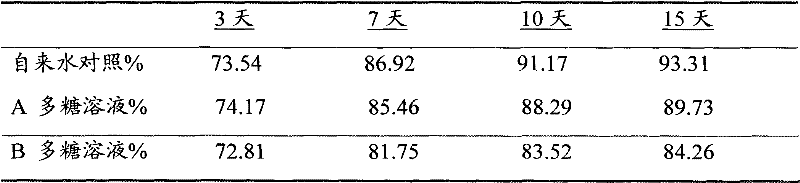

[0036] Example 1: Application example of HD-3 exopolysaccharide in foliar fertilizer

[0037] Take HD-3 exopolysaccharide 1.0‰, and other raw materials such as urea, dipotassium hydrogen phosphate, potassium sulfate, ferrous sulfate, boric acid, copper sulfate, zinc sulfate, ammonium molybdate, manganese sulfate, etc. to make nitrogen, phosphorus and potassium according to a certain ratio The content is 6%, 1.5%, 5%, respectively, and the total amount of trace elements is greater than 2%. The procedure is to dissolve 1.0g of exopolysaccharide in 1kg of tap water, turn on stirring and heat to 60°C to make it completely dissolved; then add other required raw materials, stir for 20 minutes until completely dissolved, pass through a 40-mesh sieve, and then sterilize and fill Put it in a 100mL plastic bottle and seal it, which is the finished product of polysaccharide foliar fertilizer.

Embodiment 2

[0038] Example 2: Application example of HD-3 exopolysaccharide in drip irrigation fertilizer

[0039] Take HD-3 exopolysaccharide 1.5‰, other raw materials such as urea, dipotassium hydrogen phosphate, potassium nitrate, humic acid, ferrous sulfate, boric acid, copper sulfate, zinc sulfate, ammonium molybdate, manganese sulfate, etc. Nitrogen, phosphorus and potassium content are 8%, 7%, 5%, respectively, the total amount of trace elements is more than 2%, and the drip irrigation fertilizer has an organic matter content of 30%. The procedure is to dissolve 1.5g of exopolysaccharide in 1kg of tap water, turn on and stir at 60°C to make it completely dissolved; then add biochemical fulvic acid, stir for 20 minutes until completely dissolved, add other required raw materials, and continue stirring until completely dissolved, After passing through a 40-mesh sieve, it is sterilized and filled in a 500mL plastic bottle, and sealed, which is the finished product of polysaccharide dr...

Embodiment 3

[0040] Example 3: Application example of HD-3 exopolysaccharide in bacterial fertilizer

[0041]1) Powdered bacterial fertilizer: Take HD-3 exopolysaccharide 1.2‰, other raw materials such as humic acid, attapulgite, plant ash, enteromorpha powder, diatomaceous earth, bentonite, bacterial liquid, etc., mix evenly according to a certain proportion, crush, Pass through a 100-mesh sieve, pack into bags and become a finished product of polysaccharide-containing powder bacterial fertilizer.

[0042] 2) Liquid bacterial preparation: take HD-3 exopolysaccharide 1.0‰, and other raw materials such as urea, potassium sulfate, dipotassium hydrogen phosphate, kelp puree, biochemical fulvic acid, emulsifier, bacterial liquid, etc., and mix evenly according to a certain ratio. Prepare a liquid bacterial preparation with an effective viable count greater than 1 billion / mL. The procedure is to dissolve 1.0‰ HD-3 exopolysaccharide in kelp puree, add biochemical fulvic acid, stir and keep warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com