Liquid crystal sealant composition

A technology of liquid crystal sealant and liquid crystal sealing, which is applied in the direction of adhesives, adhesive types, modified epoxy resin adhesives, etc., can solve the problems of reducing initiator reactivity, orientation disorder, and negative effects of liquid crystals, etc., to achieve increased The effects of sealing and reliability, excellent bonding performance, and convenient performance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

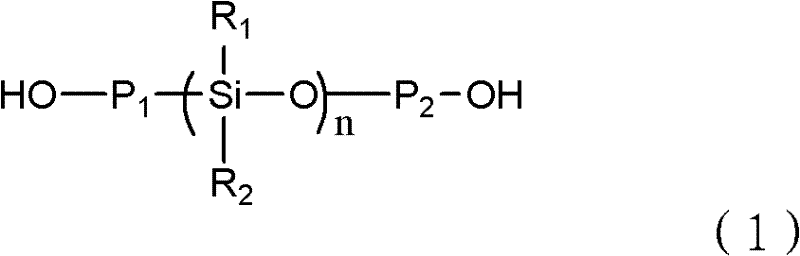

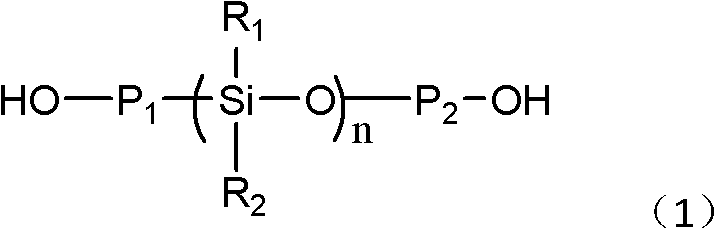

[0051] 1: Synthesis of carboxy-terminated hyperbranched silicone modified polyester (HP)

[0052] The theoretically calculated amount of (trimellitic anhydride) TMA and dialkylhydroxypolyphenylsilane (DHPS) (n(TMA): n(DHPS)=22:21) is added to the four ports with agitator, temperature control device and water separator Into the flask, add xylene and esterification catalyst, raise the temperature to 140° C. and react for 5 hours, and distill off the solvent to obtain a carboxy-terminated hyperbranched organosilicon modified polyester with an acid value of 224.02 mgKOH / g pale yellow solid.

[0053] 2: Synthesis of acrylic modified hyperbranched silicone epoxy resin (HPS-1)

[0054] The carboxyl-terminated hyperbranched silicone-modified polyester and epichlorohydrin synthesized in Example 1 were added to the reaction device at a ratio of carboxyl to epichlorohydrin of 1:2, and then an appropriate amount was added The phase transfer catalyst is heated to 110~120℃ and reacted for 2h. Aft...

Embodiment 2

[0065] 1: Synthesis of carboxy-terminated hyperbranched silicone modified polyester (HP)

[0066] The theoretically calculated amount of (trimellitic anhydride) TMA and dialkylhydroxypolyphenylsilane (DHPS) (n(TMA): n(DHPS)=22:21) is added to the four ports with agitator, temperature control device and water separator Into the flask, add xylene and esterification catalyst, raise the temperature to 140° C. and react for 5 hours, and distill off the solvent to obtain a carboxy-terminated hyperbranched organosilicon modified polyester with an acid value of 224.02 mgKOH / g pale yellow solid.

[0067] 2: Synthesis of acrylic modified hyperbranched silicone epoxy resin (HPS-2)

[0068] Add a certain amount of dialkylhydroxypolyphenylsilane to a four-necked flask equipped with a stirrer, thermometer, condenser, nitrogen tube and constant pressure funnel. Under normal temperature and stirring conditions, slowly from the constant pressure funnel Drop the IPDI trimer in the amount of 1:1. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com