Preparation method for scattering layer of dye-sensitized solar battery

A technology for solar cells and dye sensitization, which is applied in the field of preparation of photoanode of dye-sensitized solar cells, can solve the problems of inability to effectively adsorb dye molecules, low specific surface area, etc. The effect of absorptive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

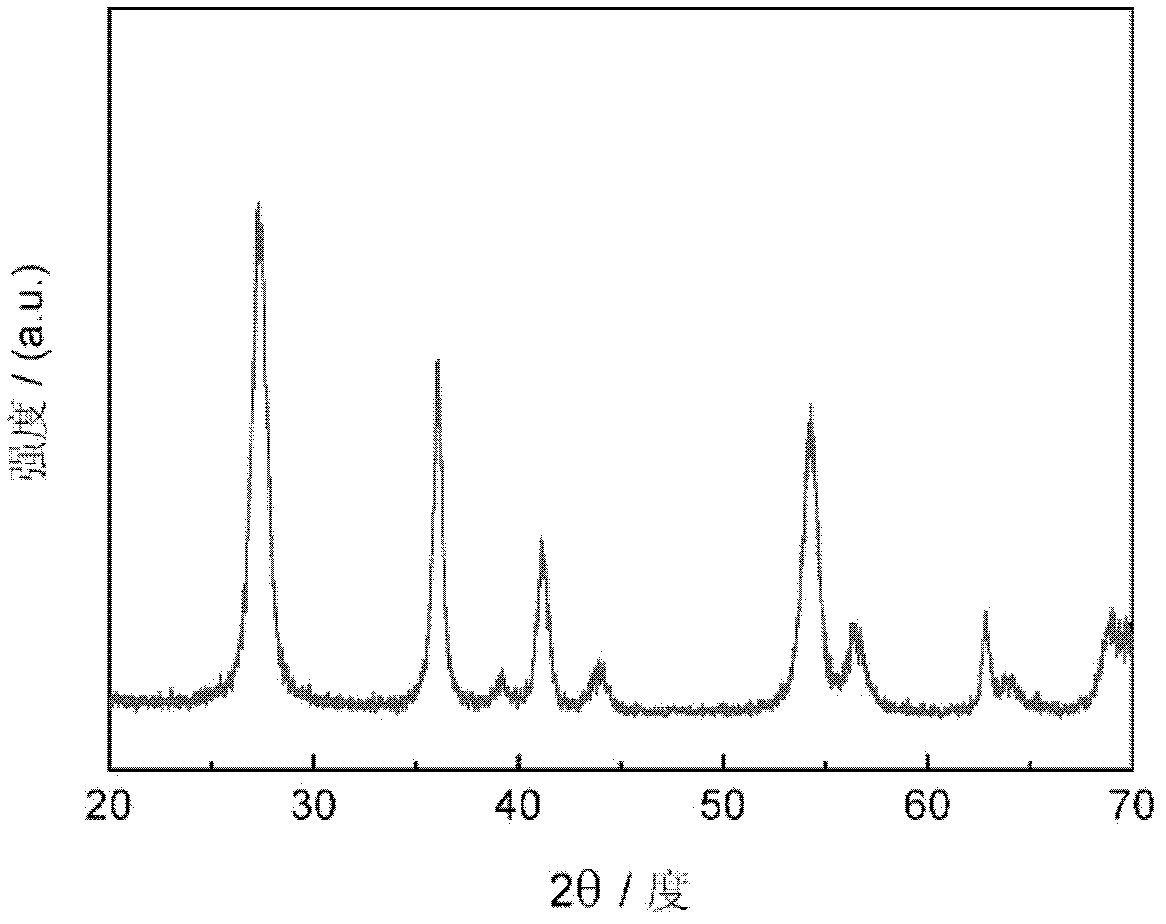

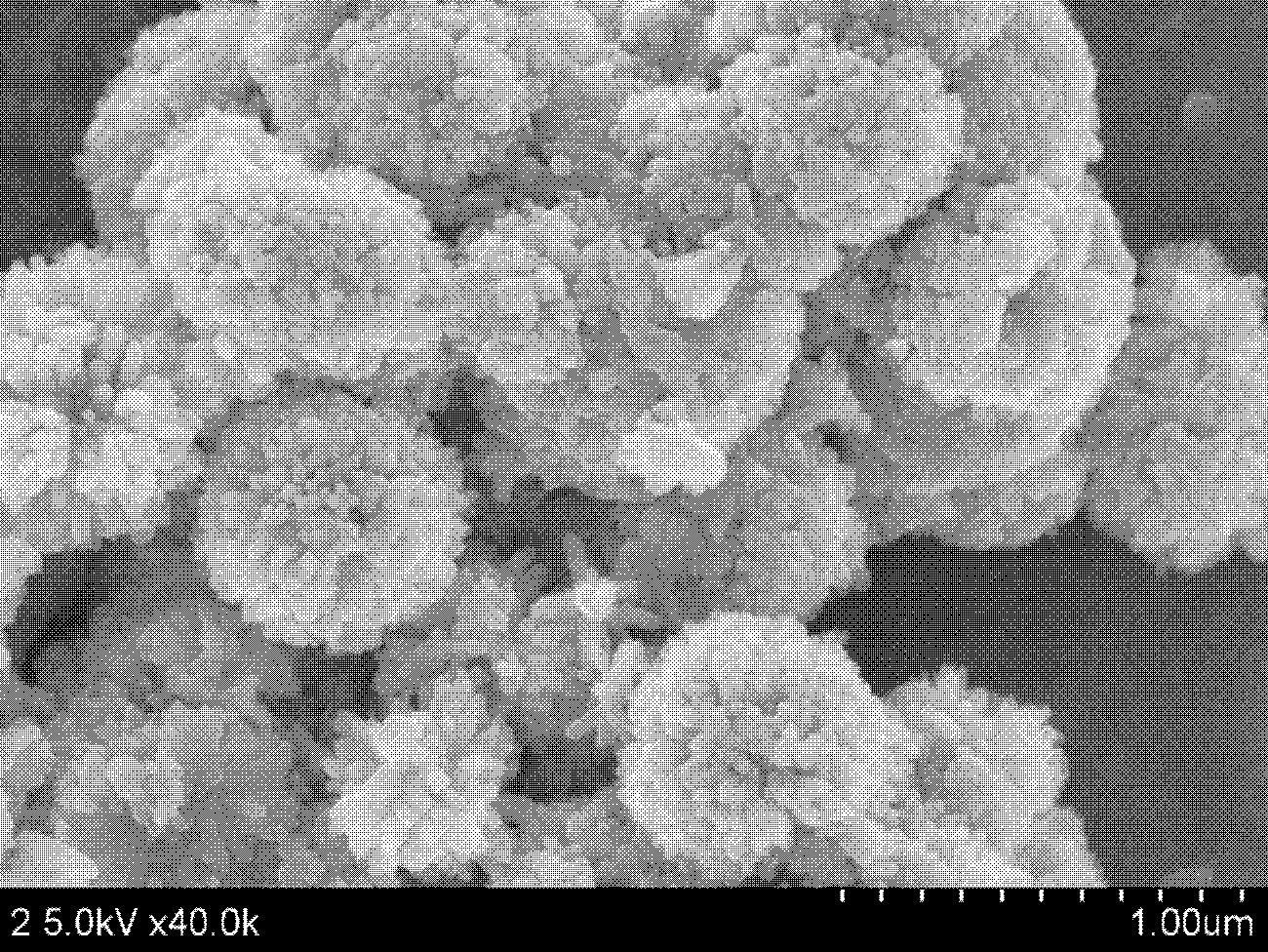

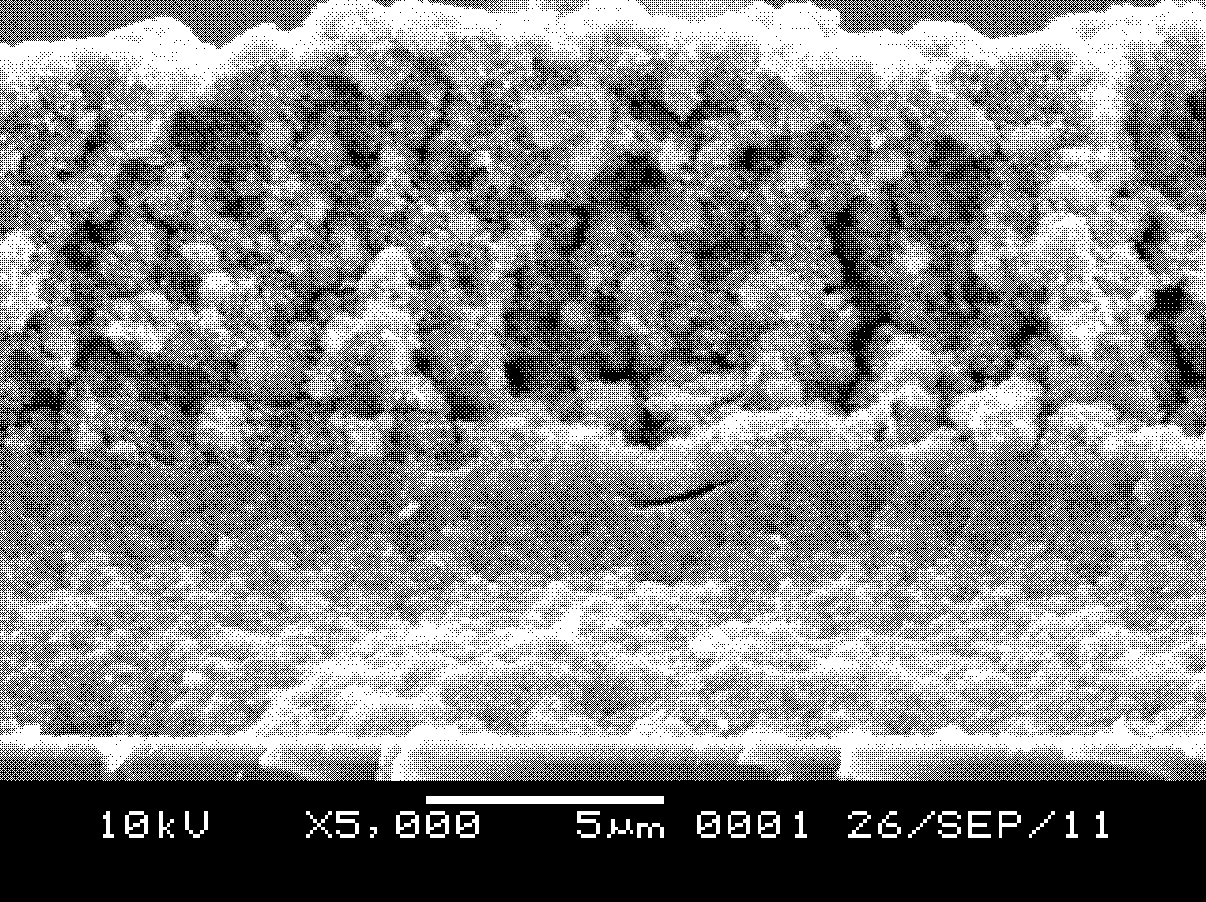

[0032] Weigh 62 grams of sodium chloride to make 340 milliliters of solution, transfer the solution to an ice-water bath environment, add 10 milliliters of titanium tetrachloride dropwise, stir while adding, and obtain a colorless and uniform mixture after the addition is completed. solution. Transfer the mixed solution to a polytetrafluoroethylene-lined reactor for hydrothermal reaction, control the reaction temperature at 120°C, and hold for 12 hours. After the heat preservation is completed and cooled to room temperature, open the hydrothermal reactor and take out the Gallbladder, pour out the precipitate, wash 3 times to remove chloride ions and sodium ions, dry the pure precipitate to obtain large particle titanium oxide scattering microsphere powder. Get a small amount of powder and carry out X-ray diffraction (XRD) analysis, XRD result shows that titanium dioxide wherein is rutile phase, as figure 1 shown. figure 2 It is the field emission scanning electron microsco...

Embodiment 2

[0034]Weigh 41 grams of sodium chloride to make 340 ml of solution, transfer the solution to an ice-water bath environment, add 10 ml of titanium tetrachloride dropwise, stir while adding, and obtain a colorless and uniform mixture after the addition is completed. solution. Transfer the mixed solution to a polytetrafluoroethylene-lined reactor for hydrothermal reaction, control the reaction temperature at 120°C, and hold for 18 hours. After the heat preservation is completed and cooled to room temperature, open the hydrothermal reactor and take out the Gallbladder, pour out the precipitate, wash 3 times to remove chloride ions and sodium ions, dry the pure precipitate to obtain large particle titanium oxide scattering microsphere powder. Weigh 2 grams of large-particle scattering microspheres and transfer them to a mortar, add 8 grams of ethylcellulose terpineol solution with a mass fraction of 10% prepared in advance, and grind the mixture of the three for 2 hours to obtain a...

Embodiment 3

[0036] Weigh 41 grams of potassium chloride to make 340 milliliters of solution, transfer the solution to an ice-water bath environment, add 10 milliliters of titanium tetrachloride dropwise, stir while adding, and obtain a colorless and uniform mixture after the addition is completed. solution. Transfer the mixed solution to a polytetrafluoroethylene-lined reactor for hydrothermal reaction, control the reaction temperature to 150°C, and hold the heat for 12 hours. Gallbladder, pour out the precipitate, wash 3 times to remove chloride ions and potassium ions, dry the pure precipitate to obtain large particle titanium oxide scattering microsphere powder. Weigh 2 grams of large-particle scattering microspheres and transfer them to a mortar, add 8 grams of polyethylene glycol 20,000 aqueous solution with a mass fraction of 10% prepared in advance, and grind the mixture of the three for 1 hour to obtain a uniform slurry. Using the method of scraping coating, a layer of slurry is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com