Low-rosin halogen and lead-free solder paste and preparation method thereof

A lead-free solder paste and rosin technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of destroying the atmospheric ozone layer, excessive surface residue, affecting performance, etc., to improve reliability and environmental standards, and reduce heavy metal pollution. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

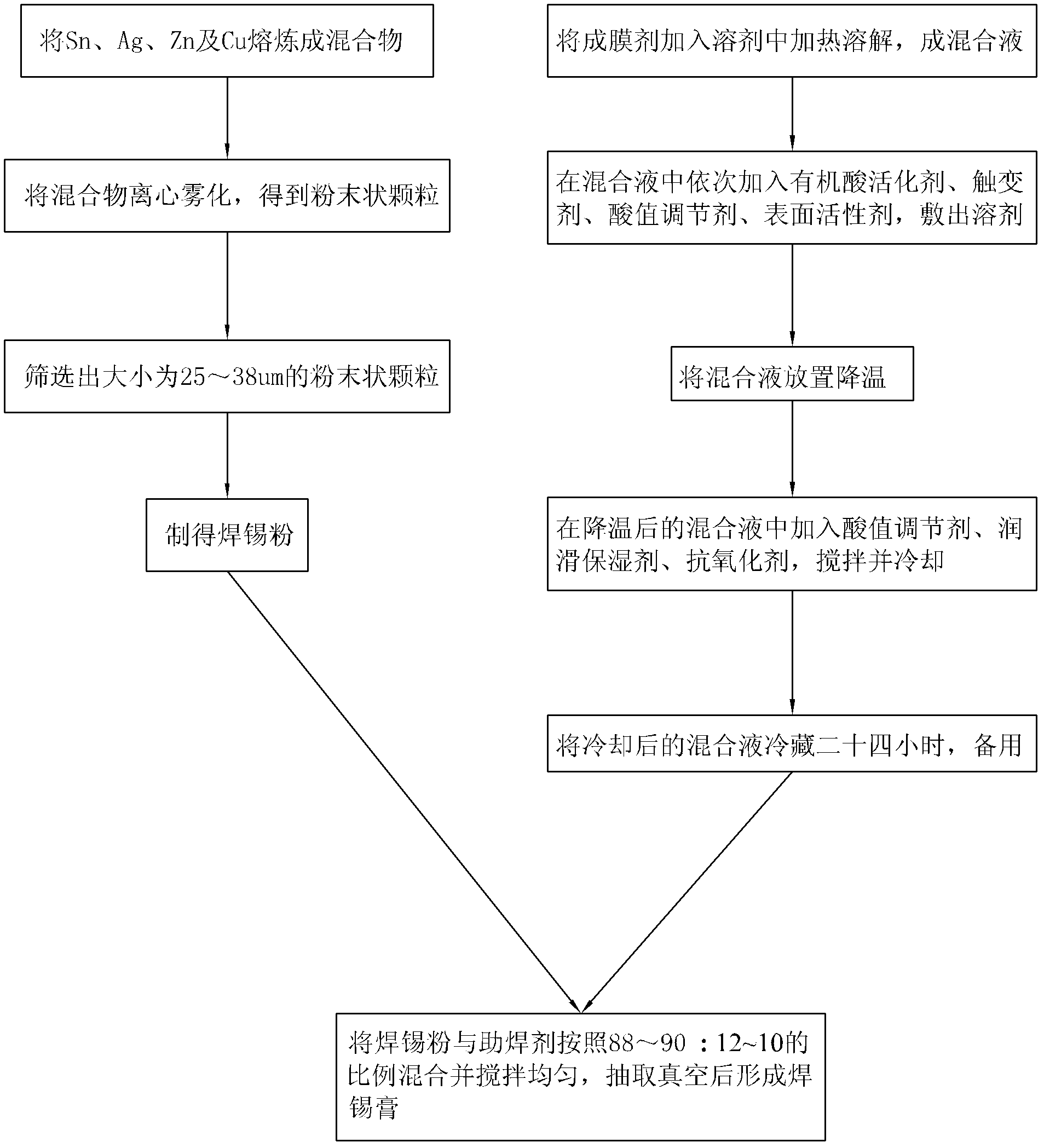

Method used

Image

Examples

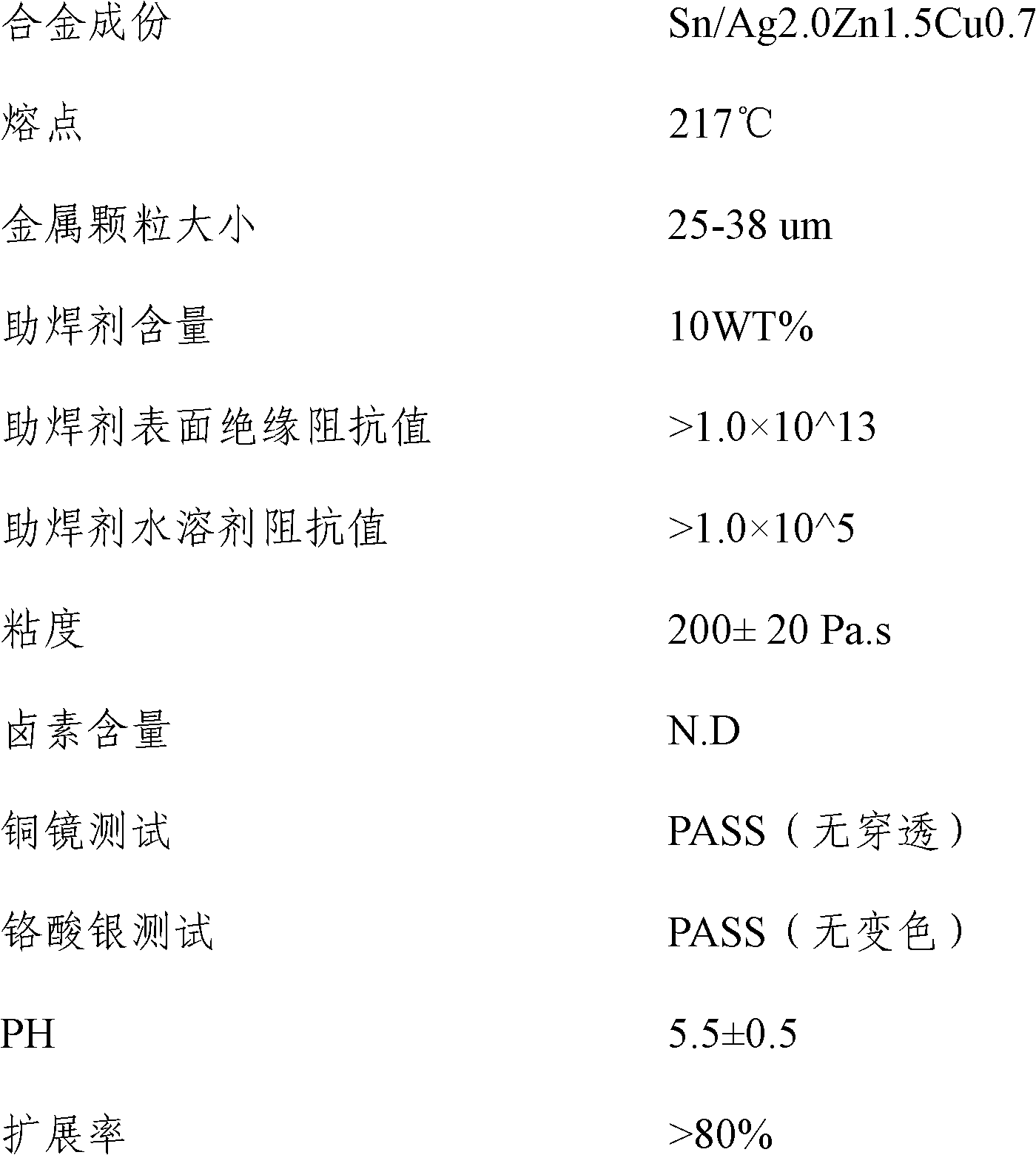

Embodiment approach 1

[0036] Solder powder: S n 、A g ,Z n 、C u Four materials according to: 95.8% S n , 2% of A g , 1.5% Z n , 0.7%. C u Melting and mixing, and centrifugal atomization, screened out the powder of 25-38um particles.

[0037] The weight percent of flux is:

[0038] The film-forming agent contains 30%: wherein, it contains 15% cellulose resin, 10% modified rosin, and 5% polyethylene glycol;

[0039] The organic acid activator contains 10%: among them, it contains 4% succinic acid, 4% adipic acid, and 2% itaconic acid;

[0040] The surfactant contains 4%: Among them, it contains 4% nonylphenol polyoxyethylene ether;

[0041] Thixotropic agent contains 6%: among them, contains 6% hydrogenated castor oil;

[0042] The acid value regulator contains 5%: among them, it contains 3% diethanolamine and 2% oleic acid amide;

[0043] The lubricating moisturizer contains 3%: among them, 3% contains paraffin;

[0044] Antioxidants contain 2%: among them, 2% benzotriazole;

[0045] The...

Embodiment approach 2

[0050] Solder powder: S n 、A g ,Z n 、C u Four materials according to: 95.8% S n , 2% of A g , 1.5% Z n , 0.7%. C u Melting and mixing, and centrifugal atomization, screened out the powder of 25-38um particles.

[0051] The weight percent of flux is:

[0052] The film-forming agent contains 35%: among them, it contains 15% of cellulose resin, 10% of modified rosin, 5% of polyethylene glycol, and 5% of acrylic resin;

[0053]The organic acid activator contains 8%: among them, it contains 4% glutaric acid and 4% sebacic acid;

[0054] The surfactant contains 3%: among them, it contains 3% diethylene glycol polyoxyethylene ether;

[0055] Thixotropic agent contains 6%: 6% hydrogenated castor oil;

[0056] The acid value regulator contains 5%: among them, it contains 4% triethanolamine and 1% oleic acid amide;

[0057] The lubricating moisturizer contains 2%: Among them, it contains 2% glycerol;

[0058] Antioxidant contains 1%: Among them, it contains 1% BHT;

[0059]...

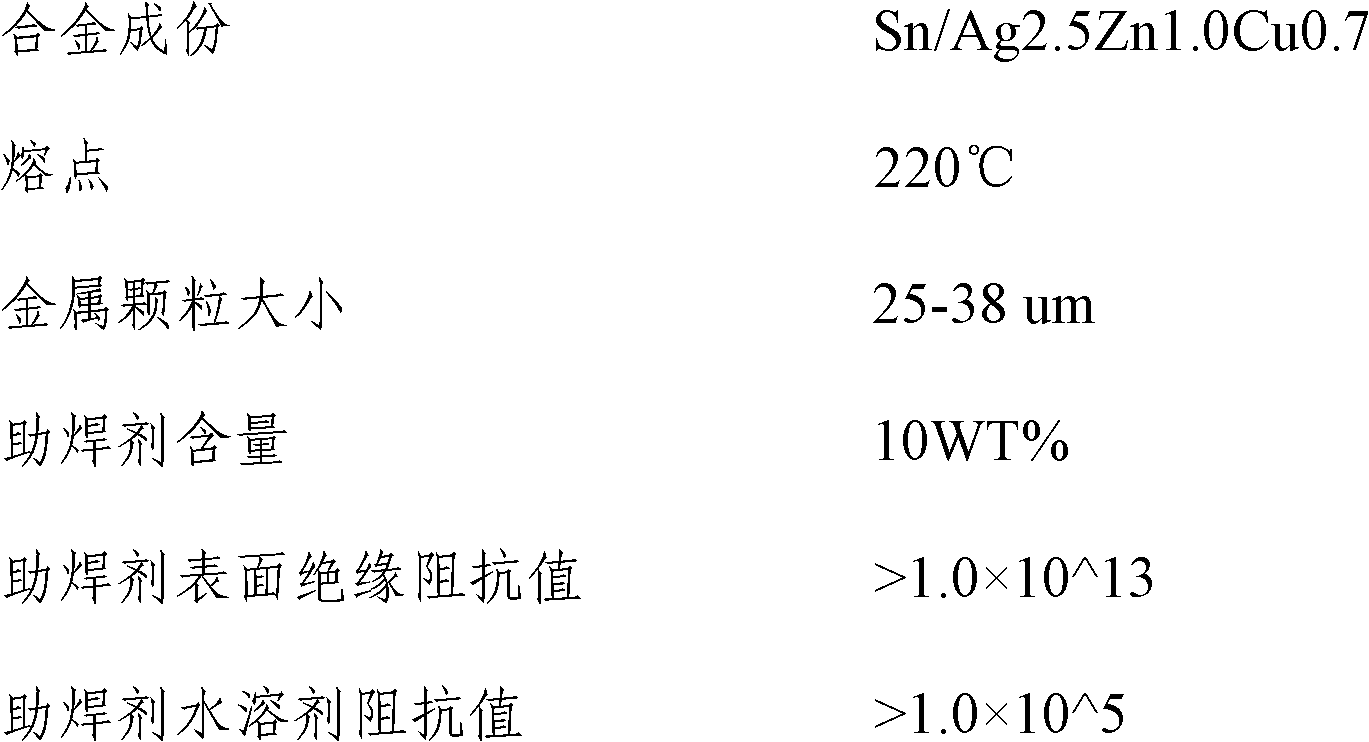

Embodiment approach 3

[0065] Solder powder: S n 、A g ,Z n 、C u Four materials according to: 96.3% S n , 2.5% A g , 0.5% Z n , 0.7%. C u Melting and mixing, and centrifugal atomization, screened out the powder of 25-38um particles.

[0066] The weight percent of flux is:

[0067] The film-forming agent contains 25%: wherein, it contains 10% cellulose resin, 10% modified rosin, and 5% polyethylene glycol;

[0068] The organic acid activator contains 8%: among them, it contains 4% succinic acid and 4% DL-malic acid;

[0069] The surfactant contains 3%: among them, it contains 3% oleyl alcohol polyoxyethylene ether;

[0070] Thixotropic agent contains 6%: among them, contains 6% hydrogenated castor oil;

[0071] The acid value regulator contains 5%: among them, it contains 4% triethanolamine and 1% oleic acid amide;

[0072] The lubricating moisturizer contains 2%: Among them, it contains 2% propylene glycol;

[0073] Antioxidant contains 1%: Among them, it contains 1% imidazole;

[0074] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com