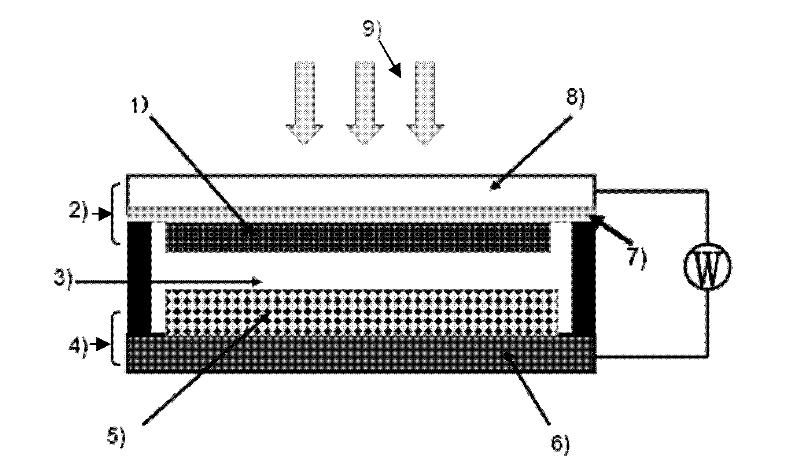

Carbon counter electrode for dye-sensitized solar cell and preparation method for carbon counter electrode

A solar cell and dye sensitization technology, applied in the field of carbon counter electrode and its preparation, can solve the problems of high manufacturing cost of DSSC, achieve low manufacturing cost, strong resistance to electrolyte corrosion, and promote commercialization and popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

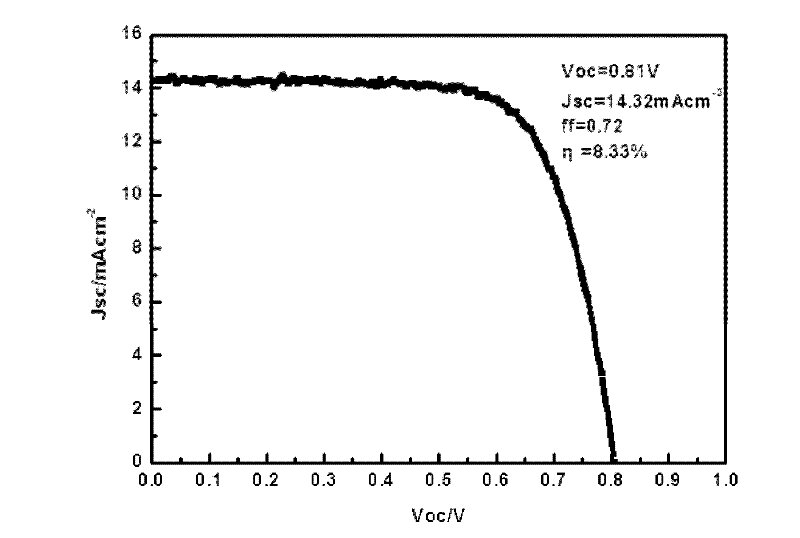

Embodiment 1

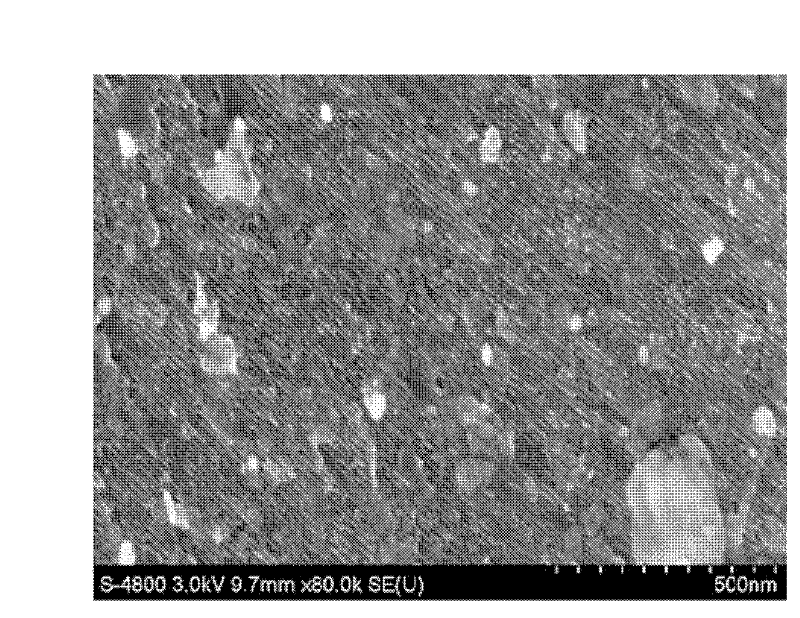

[0035] Weigh 4g of coal powder with a particle size of 10μm, add 1g of conductive graphite and 0.2g of carboxymethyl cellulose, mix evenly, use a hydraulic press to cold press under a pressure of 50MPa to prepare a carbon plate, and then pass through 900 under a nitrogen atmosphere. ℃ carbonization to prepare a carbon substrate with a thickness of about 2.0mm and a resistance of 134mΩ / □. Use the DMAc solution of mesoporous phenolic resin with a mass percentage of 14% as the polymer solution, compound it on the carbon substrate by spin coating, heat and dry it in an oven at 80°C for 24 hours, and form a thin polymer layer on the carbon substrate , placed in a carbonization furnace under the protection of argon, the polymer film is carbonized at 750°C to form an integrated pure carbon counter electrode with a catalytic active carbon layer; the catalytic active carbon layer is a disordered mesoporous structure with a thickness of about 8 μm and a pore diameter of about 5.5 nm, th...

Embodiment 2

[0037] Weigh 4g of coal powder with a particle size of 5μm, add 1.5g of conductive carbon black and 0.2g of carboxymethyl cellulose, mix evenly, and use a hydraulic press to cold-press under a pressure of 30MPa to prepare a carbon plate, and then under a nitrogen atmosphere After carbonization at 950°C, a carbon substrate was prepared with a thickness of about 1mm and a resistance of 0.2Ω / □. At the same time, the DMAc solution of mesoporous polyimide, mesoporous phenolic resin, mesoporous polyarylether ketone, benzoxazine resin, polyether sulfone ketone and cyanate resin with a mass percentage of 12% is used as the polymer solution, and the The method of spin coating is compounded on the carbon substrate that has been polished and polished on the surface, heated to 60°C in an oven for 24 hours according to the program, and a thin porous polymer layer is formed on the substrate, which is placed in a carbonization furnace under the protection of argon. An integrated carbon count...

Embodiment 3

[0041] Weigh 4g of plant-based carbon powder with a particle size of 3μm, add 1.0g of carbon fiber and 0.5g of phenolic resin, mix evenly, and use a hydraulic press to cold-press under a pressure of 25MPa to prepare a carbon plate, and carbonize it at 1000°C under a nitrogen atmosphere , to prepare a carbon substrate with a thickness of about 1.2mm and a resistance of 679mΩ / □. Use mesoporous polyimide DMAc solution with a mass percentage of 10% as the polymer solution, compound it on the carbon substrate by spraying, heat and dry in an oven at 60°C for 20 hours, form a thin polymer layer on the substrate, and put Into the carbonization furnace under the protection of argon, the polymer film is carbonized at 750 °C to form an integrated pure carbon counter electrode with a catalytic active carbon layer; the catalytic active carbon layer is a disordered micro-mesoporous structure with a thickness of 1 μm and a pore diameter of about 5 nm. Surface area is 720m 2 g -1 At the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com