Method for using activated carbon load copper oxide composite catalyst to absorb nitrogenous oxide

A composite catalyst, nitrogen oxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of poor application effect, affecting the reaction activity and reaction stability of carbonaceous solids, and decreasing reaction conversion rate, etc. problem, to achieve the effect of improving the ability of reaction activity and reaction stability, strong practical value, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

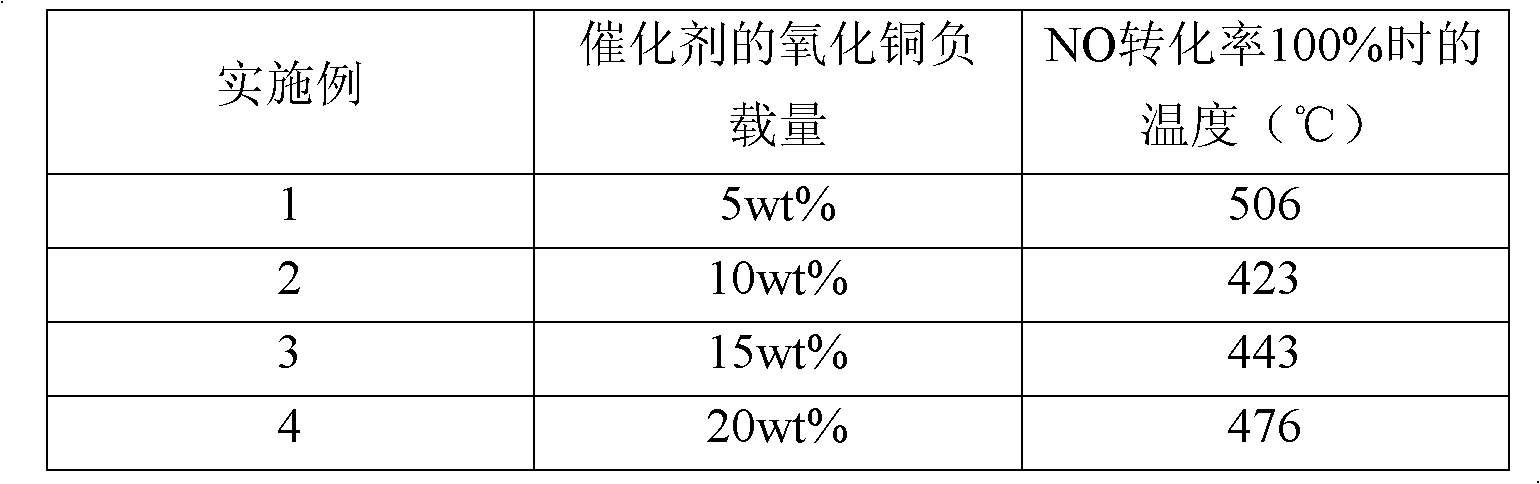

[0031] Grind the commercially available coconut shell catalytic activated carbon (GB / T12496-1999) to make the particle size 40-60 mesh; then put 2mol / L HNO 3 The solution was treated at 40°C for 4 hours; cooled, filtered, washed with deionized water until neutral, and dried in a drying oven at 100°C for later use. Take 0.65g, 1.29g, 1.95g, 2.58g of copper nitrate and add 50ml of water to make a solution, add 5g of activated carbon after treatment, stir at medium speed for 1h at room temperature, dip for 4h at 60°C, put it in a drying oven at 120°C The loaded activated carbon was dried for 2 hours; the dried activated carbon loaded with copper salt was added to a box-type resistance furnace, and under the protection of nitrogen, it was calcined at 400°C for 2 hours, and the final product was obtained after cooling. The copper oxide loading in the activated carbon was respectively 5wt%, 10wt%, 15wt%, 20wt%.

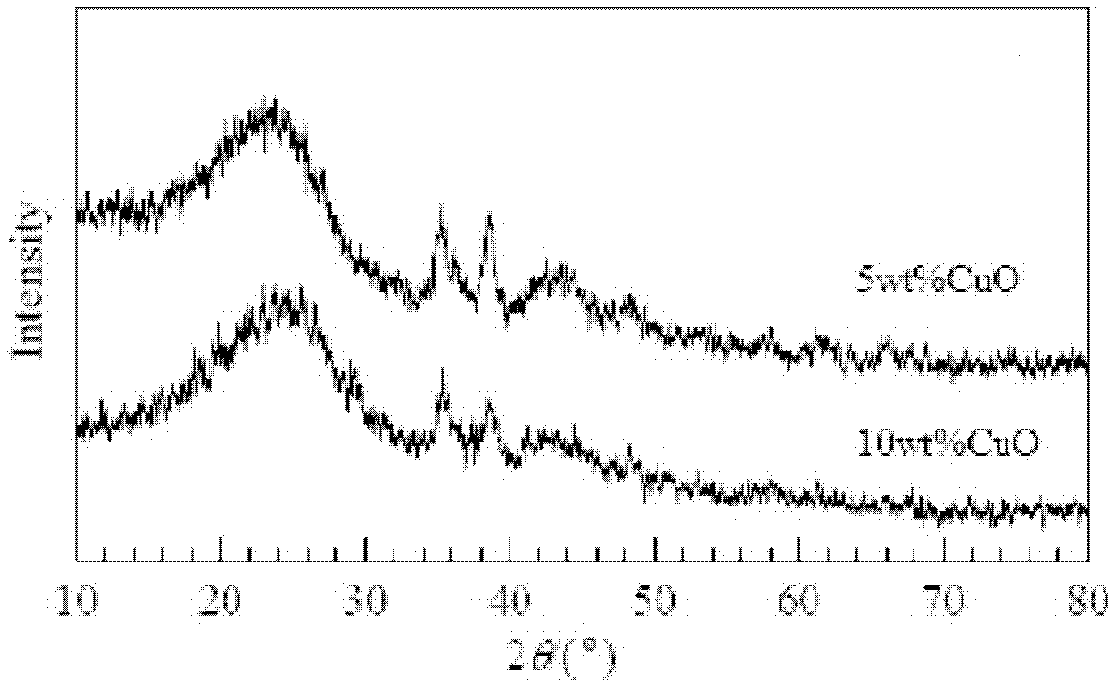

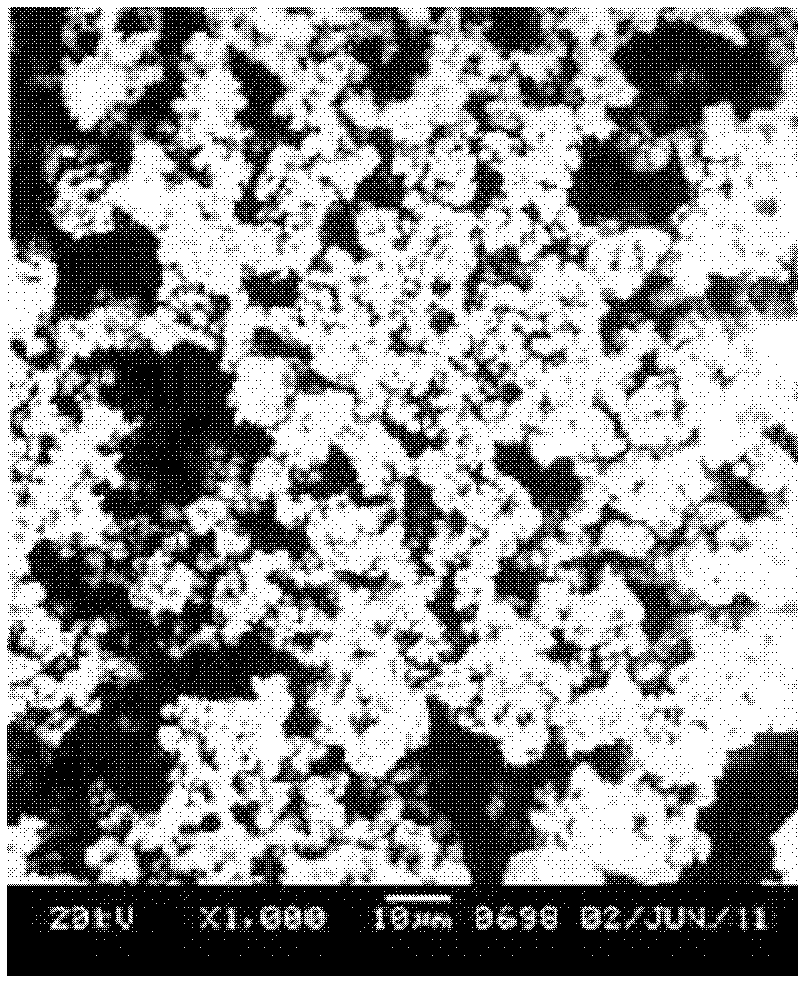

[0032] With gained 5wt%, the catalyst product of 10wt% uses XRD, SEM ...

Embodiment 5~8

[0038] Grind the commercially available coconut shell catalytic activated carbon so that the particle size is 40-60 mesh; then add 3mol / L HNO 3The solution was treated at 50°C for 3 hours; cooled, filtered, washed with deionized water until neutral, and dried in a drying oven at 110°C for later use. Take 0.55g, 0.11g, 1.67g, 2.22g of copper sulfate and add them into 50ml of water to make a solution, add 5g of activated carbon after treatment, stir at medium speed for 1h at room temperature, soak at 60°C for 4h, put them in a drying oven at 120°C The loaded activated carbon was dried for 2 hours; the dried activated carbon loaded with copper salt was added to a box-type resistance furnace, and under the protection of nitrogen, it was calcined at 400°C for 2 hours, and the final product was obtained after cooling. The copper oxide loading in the activated carbon was respectively 5wt%, 10wt%, 15wt%, 20wt%.

[0039] Put 1g of catalysts with copper oxide loadings of 5wt%, 10wt%, 1...

Embodiment 9~12

[0043] Grind commercially available coconut shell catalytic activated carbon to make the particle size 40-60 mesh; then add 2mol / L HNO 3 The solution was treated at 60°C for 3 hours; cooled, filtered, washed with deionized water until neutral, and dried in a drying oven at 110°C for later use. Take 0.47g, 0.94g, 1.41g, 1.88g of copper chloride and add 50ml of water to form a solution, add 5g of activated carbon after treatment, stir at medium speed for 1h at room temperature, dip for 4h at 60°C, put it in a drying oven at 120°C The loaded activated carbon was dried for 2 hours; the dried activated carbon loaded with copper salt was added to a box-type resistance furnace, under the protection of nitrogen, it was calcined at 450°C for 2 hours, and the final product was obtained after cooling. The copper oxide loading in the activated carbon was 5wt%, 10wt%, 15wt%, 20wt%, respectively.

[0044] Put 1g of catalysts with copper oxide loadings of 5wt%, 10wt%, 15wt%, and 20wt% into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com