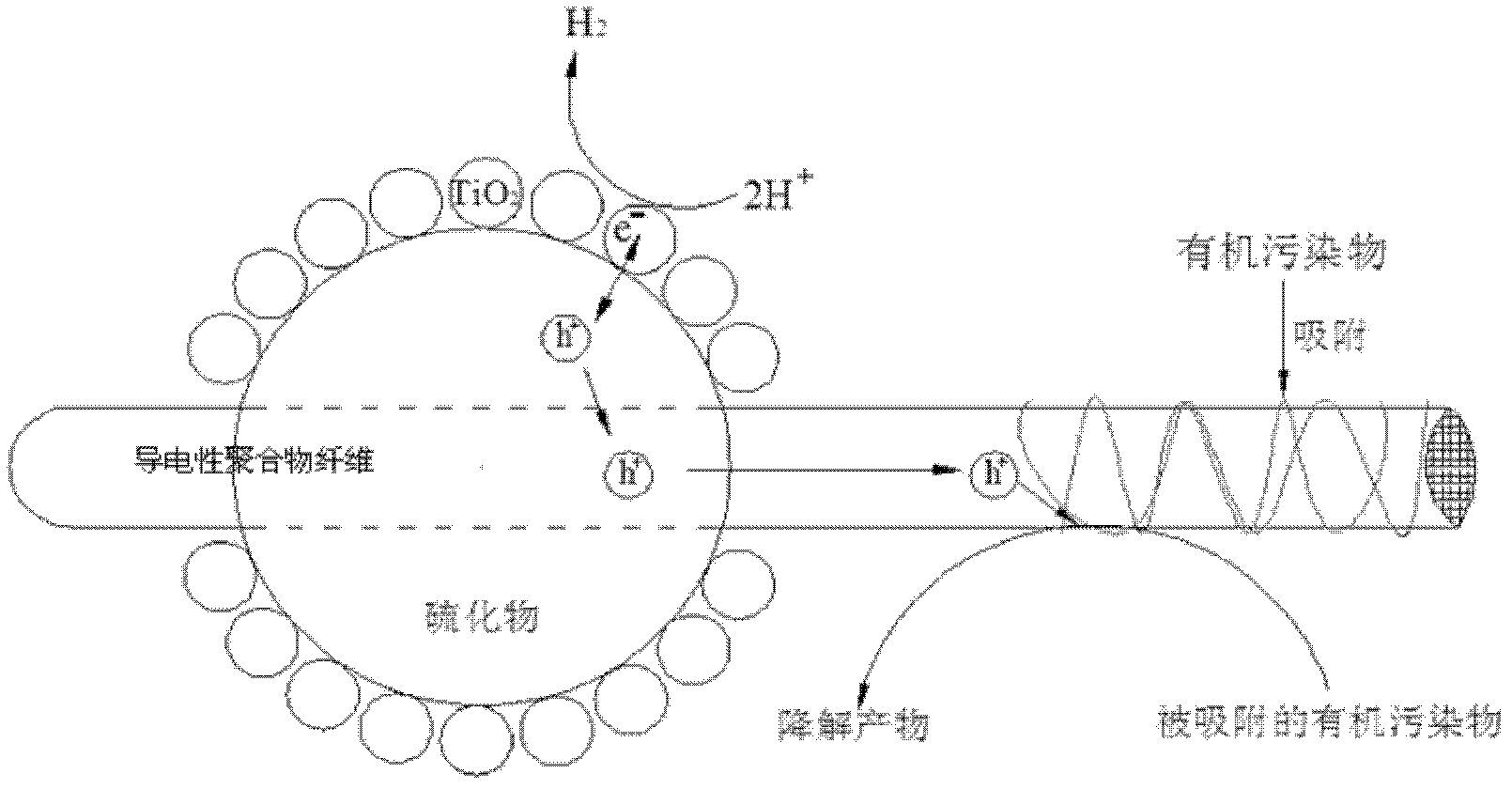

Semiconductor hetero-junction/conductive polymer fiber membrane composite photocatalyst and preparation method thereof

A conductive polymer, fiber membrane technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of small specific surface area, low flexibility and carrier cost Advanced problems, to achieve the effect of improving catalytic performance, low surface tension, and inhibiting deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

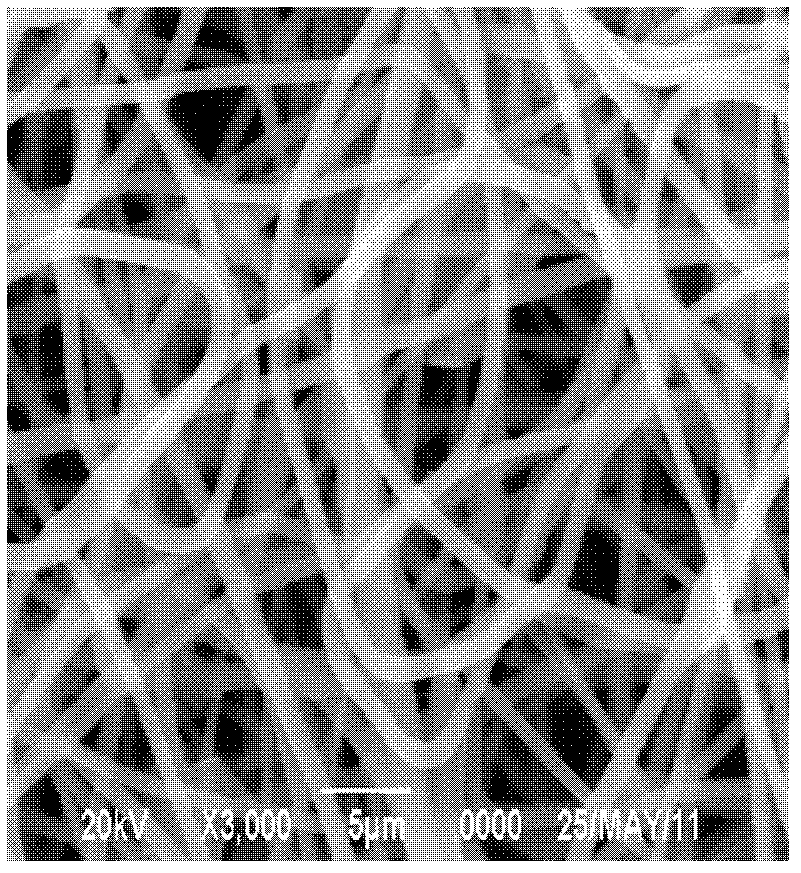

[0051] Add 3.6g of double-part A-type polysulfone, 0.41g of styrene-maleic anhydride copolymer and 0.4g of nano-graphite into a mixed solvent of 14mL of acetone and 20mL of N,N-dimethylacetamide, and stir for 24 hours. Then electrospin on a high-voltage electrospinning device to obtain a conductive polymer fiber film with a fiber diameter of 400 nm-2 μm.

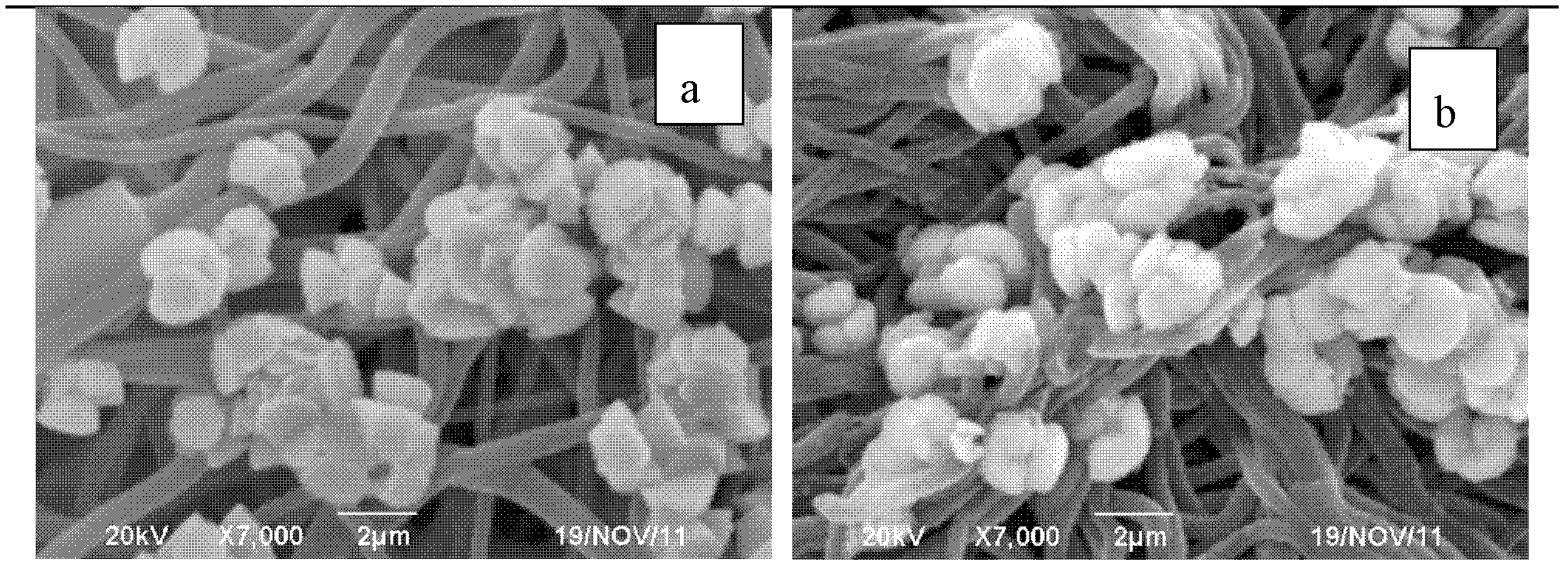

[0052] Immerse the conductive polymer fiber membrane prepared above into 25mL 0.25mol L -1 of cadmium chloride and 25mL of 0.25mol·L -1 Soak in the mixed aqueous solution of tin tetrachloride for 12 hours at room temperature, so that Cd 2+ , Sn 4+ Fully complex with the carboxyl group on the surface of the conductive polymer fiber, then dry at 50°C for 6 hours under the protection of nitrogen; then place it in a 50mL hydrothermal reaction kettle, add 40mL0.25mol L -1 thioacetamide aqueous solution, heated at 120°C for 12h, cooled naturally to room temperature, took out the reaction product, put it in 50mL deionized water ...

Embodiment 2

[0057] 20 g of methacrylic acid, 60 g of hexafluorobutyl acrylate and 0.4 g of azobisisobutyronitrile were added into a three-necked flask protected with nitrogen and stirred, using butanone as a solvent, and reacted at 70° C. for 4 hours. After the reaction, precipitate in 10 times the volume of deionized water, and vacuum-dry at 60° C. to constant weight to obtain a hexafluorobutyl acrylate-methacrylic acid copolymer.

[0058] Add 5.1g of polyvinylidene fluoride, 0.78g of hexafluorobutyl acrylate-methacrylic acid copolymer and 0.1g of carbon nanotubes into 40.0g of N,N-dimethylformamide, and stir for 24h. Then electrospin on a high-voltage electrospinning device to obtain a conductive polymer fiber film with a fiber diameter of 400 nm-2 μm.

[0059] Immerse the conductive polymer fiber membrane prepared above into 25ml 0.25mol L -1 Zinc acetate and 25ml 0.25mol L -1 In the mixed solution of cadmium chloride, soak at room temperature for 20 hours, so that Zn 2+ 、Cd 2+ Ful...

Embodiment 3

[0064] Add 2.5g polyphenylene sulfone, 1.0g styrene-maleic anhydride copolymer, 0.8g polyvinylidene fluoride and 0.3g nano-carbon black to the mixed solvent of 8.0g acetone and 22.0g N, N-dimethylacetamide , stirred for 24 hours. Then, electrospinning is performed on a high-voltage electrospinning device to obtain a conductive polymer fiber film with a fiber diameter of 400 nm-2 μm.

[0065] Immerse the conductive polymer fiber membrane prepared above to 50 mL, 0.25 mol L -1 cadmium chloride aqueous solution, soaked at room temperature for 24 hours, so that Cd 2+ Fully complex with the carboxyl group on the surface of the conductive polymer fiber, and then dry at 60°C for 6 hours under the protection of nitrogen; then place it in a 50mL hydrothermal reaction kettle, add 40.0mL 0.4mol L -1 The aqueous solution of thioacetamide was reacted at 120°C for 12 hours, and cooled naturally to room temperature. The reaction product was taken out and placed in 50 mL of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com