Transparent ceramic white light emitting diode (LED) and preparation method thereof

A technology of transparent ceramics and LED chips, applied in the field of white light LEDs, can solve the problems of poor heat dissipation performance, low light extraction rate, accelerated phosphor aging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

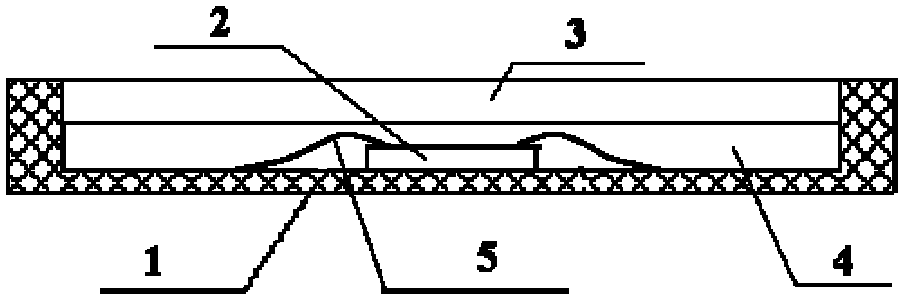

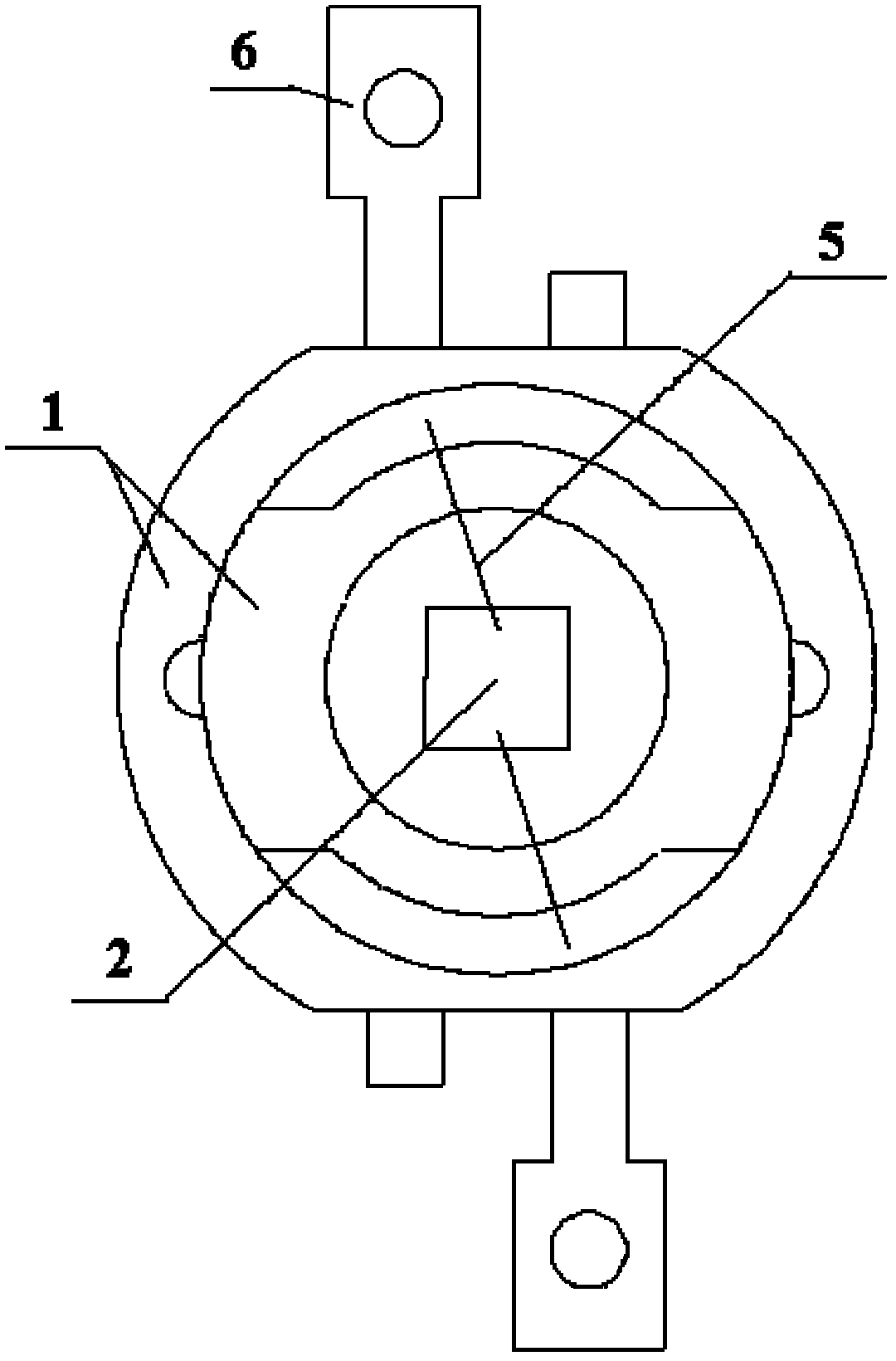

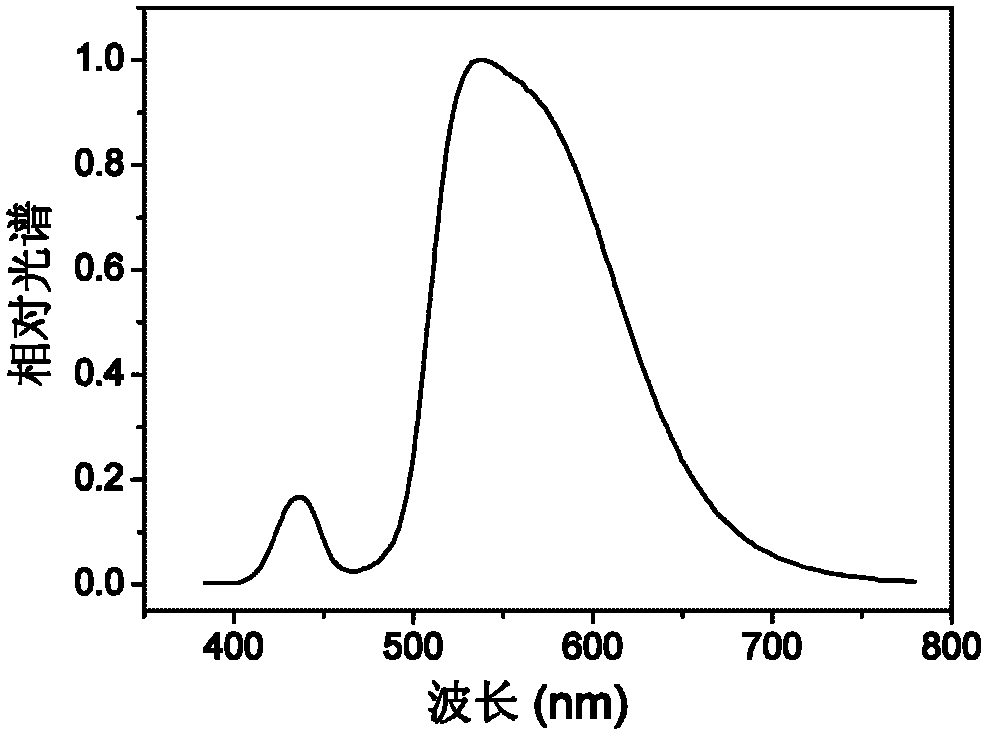

[0030] In this embodiment, the structure of the transparent ceramic white light LED is as follows figure 1 , figure 2As shown, it includes a support 1, a blue LED chip 2 and a cerium-doped yttrium aluminum garnet transparent ceramic sheet 3, the support is a circular frustum with grooves, and the cerium-doped yttrium aluminum garnet transparent ceramic sheet 3 is a circle with a thickness of 1 mm. sheet, with the chemical formula (Y 0.995 Ce 0.005 ) 3 al 5 o 12 The material is made, and the preparation method is as follows: according to the composition in the above chemical formula, Y(NO 3 ) 3 , NH 4 Al(SO 4 ) 2 , Ce(NO 3 ) 3 , set Y(NO 3 ) 3 , NH 4 Al(SO 4 ) 2 , Ce(NO 3 ) 3 Dissolve in deionized water and mix well to prepare Al 3+ A mixed salt solution with a concentration of 0.1mol / L. Will NH 4 HCO 3 Soluble in ethanol-water complex solvent to prepare NH 4 HCO 3 A precipitant solution with a concentration of 1mol / L, the volume ratio of ethanol to wat...

Embodiment 2

[0037] In this embodiment, the structure of the transparent ceramic white light LED is as follows figure 1 , figure 2 As shown, it includes a support 1, a blue LED chip 2 and a cerium-doped yttrium aluminum garnet transparent ceramic sheet 3, the support is a circular frustum with grooves, and the cerium-doped yttrium aluminum garnet transparent ceramic sheet 3 is a circle with a thickness of 1 mm. sheet, with the chemical formula (Y 0.999 Ce 0.001 ) 3 al 5 o 12 The material is made, and the preparation method is as follows: according to the composition in the above chemical formula, Y(NO 3 ) 3 , NH 4 Al(SO 4 ) 2 , Ce(NO 3 ) 3 , set Y(NO 3 ) 3 , NH 4 Al(SO 4 ) 2 , Ce(NO 3 ) 3 Dissolve in deionized water and mix well to prepare Al 3+ A mixed salt solution with a concentration of 0.15mol / L. Will NH 4 HCO 3 Soluble in ethanol-water complex solvent to prepare NH 4 HCO 3 Concentration is the precipitant solution of 0.5mol / L, the volume ratio of described et...

Embodiment 3

[0044] In this embodiment, the structure of the transparent ceramic white light LED is as follows figure 1 , figure 2 As shown, it includes a support 1, a blue LED chip 2 and a cerium-doped yttrium aluminum garnet transparent ceramic sheet 3, the support is a circular frustum with grooves, and the cerium-doped yttrium aluminum garnet transparent ceramic sheet 3 is a circle with a thickness of 1 mm. sheet, with the chemical formula (Y 0.9995 Ce 0.0005 ) 3 al 5 o 12 The material is made, and the preparation method is as follows: according to the composition in the above chemical formula, Y(NO 3 ) 3 , Al(NO 3 ) 3 , Ce(NO 3 ) 3 , set Y(NO 3 ) 3 , Al(NO 3 ) 3 , Ce(NO 3 ) 3 Dissolve in deionized water and mix well to prepare Al 3+ A mixed salt solution with a concentration of 0.2mol / L. Will NH 4 HCO 3 Soluble in ethanol-water complex solvent to prepare NH 4 HCO 3 A precipitant solution with a concentration of 2mol / L, the volume ratio of ethanol to water is 1.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com