Catalytic distillation production method for biodiesel

A technology of biodiesel and catalytic distillation, which is applied in the fields of biofuel, petroleum industry, fatty acid esterification, etc., can solve the problems of wastewater treatment, limiting the source of biodiesel raw materials, environmental pollution, etc., so as to reduce consumption, have a good market prospect, The effect of amplifying the source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

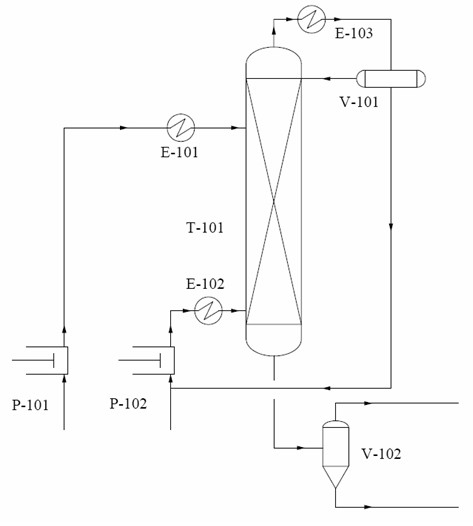

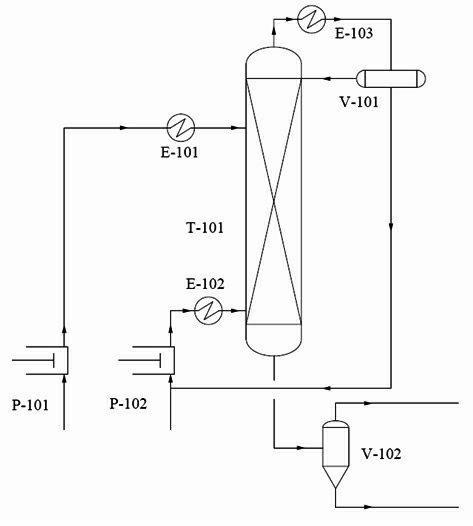

[0032] (1) Pump the gutter oil into the device through the grease feed pump P-101 at a flow rate of 10.0 kg / h, and preheat it to 65°C through the grease preheater E-101, while methanol is injected at a flow rate of 1.53 kg / h Pumped into the device through the low-carbon alcohol feed pump P-102, and preheated to 65°C through the low-carbon alcohol preheater E-102;

[0033] (2) Pass the preheated waste oil into the upper part of the catalytic rectification tower filled with solid acid or alkali catalyst, and pass the preheated methanol into the catalytic rectification tower filled with solid acid or alkali catalyst at a flow rate of 1.53kg / h In the lower part, the two are in countercurrent contact, and esterification or transesterification occurs on a solid acid or alkali catalyst bed;

[0034] The operating conditions of the catalytic rectification tower are normal pressure, reflux ratio 1.0, tower top temperature 64.6°C, tower bottom temperature 186.0°C;

[0035] The height o...

example 2

[0038] (1) Pump the frying waste oil into the device through the oil feed pump P-101 at a flow rate of 12.0 kg / h, and preheat it to 70°C through the oil preheater E-101, and at the same time, add methanol at a flow rate of 1.60 kg / h The flow rate is pumped into the device through the low-carbon alcohol feed pump P-102, and preheated to 70°C by the low-carbon alcohol preheater E-102;

[0039] (2) Pass the preheated frying waste oil into the upper part of the catalytic distillation column filled with solid acid or alkali catalyst, and pass the preheated methanol into the catalytic distillation column filled with solid acid or alkali catalyst at a flow rate of 1.53kg / h. In the lower part of the distillation tower, the two are in countercurrent contact, and esterification or transesterification occurs on a solid acid or alkali catalyst bed;

[0040] The operating conditions of the catalytic rectification tower are normal pressure, reflux ratio 1.2, tower top temperature 64.3°C, to...

example 3

[0044] (1) Pump palm oil into the device through the oil feed pump P-101 at a flow rate of 22.0 kg / h, and preheat it to 78°C through the oil preheater E-101, while ethanol is fed at a flow rate of 4.61 kg / h Pumped into the device through the low-carbon alcohol feed pump P-102, and preheated to 78°C through the low-carbon alcohol preheater E-102;

[0045] (2) Pass the preheated palm oil into the upper part of the catalytic rectification tower packed with solid acid or alkali catalyst, and the ethanol is passed into the lower part of the catalytic rectification tower packed with solid acid or alkali catalyst at a flow rate of 9.32kg / h. Countercurrent contact, esterification or transesterification occurs on a solid acid or base catalyst bed;

[0046] The operating conditions of the catalytic rectification tower are normal pressure, reflux ratio 1.0, tower top temperature 77.6°C, tower bottom temperature 192.7°C;

[0047] The height of the solid base catalyst bed is 1.8m.

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com