Preparation method of load-type silver nano-composite material

A nano-composite material, a technology of supported silver, applied in nanotechnology and other directions, can solve the problems affecting the uniformity and controllability of the size of silver nanoparticles, and the nucleation and growth of silver nanoparticles cannot be well controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

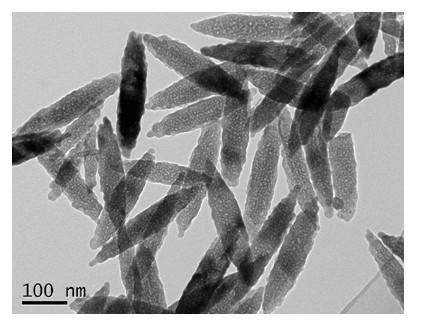

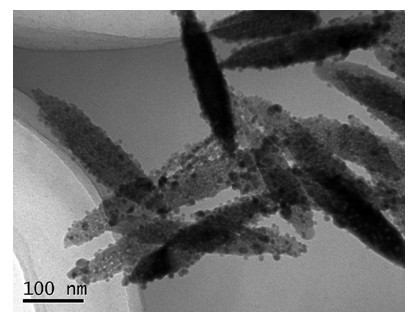

[0037]Dissolve 7 mg of sodium dihydrogen phosphate in 100 ml of water; after complete dissolution, transfer the solution to a 100 ml single-necked flask and heat to 95 °C. Then 1.8 ml of 1.48 M ferric chloride aqueous solution was added dropwise in the flask, and the mixed solution was heated to 100 °C, and naturally cooled to room temperature after reflux for 14 hours. The obtained precipitate is separated by centrifugation, and then washed several times with double distilled water and ethanol respectively, and the obtained is ferric oxide nanoparticles. The Fe2O3 nanoparticles obtained from the reaction under the transmission electron microscope were spindle-shaped, with a long diameter of about 250 nm and a short diameter of about 60 nm, such as figure 1 shown.

[0038] At room temperature, add 0.25 ml of 3-aminopropyltriethoxysilane ethanol solution with a volume ratio of 1:49 to 50 ml of 0.4 mg / ml iron oxide ethanol solution. Magnetic stirring, reaction 2 h.

[0039] A...

Embodiment 2

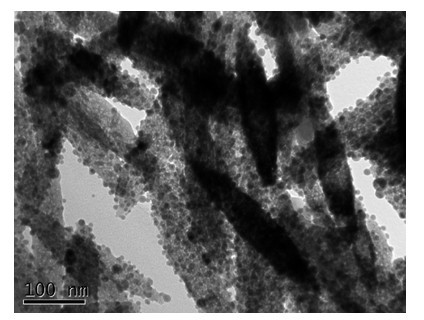

[0042] In a three-necked flask, dissolve 0.11 g sodium dodecyl sulfate and 0.1 g potassium persulfate in a mixed solution of ethanol (95%) / water (50ml:20ml), and stir under the protection of argon. Add 4.5 ml of styrene monomer dropwise to the solution, heat to 70 °C, and react for 8 h. After the reaction, the emulsion is centrifuged, washed several times and dispersed in ethanol. The product obtained after separation and washing is polystyrene microspheres. Observed by transmission electron microscope, the particle size of the polystyrene microspheres obtained by the reaction is about 500 nm, such as Figure 4 shown.

[0043] At room temperature, add 0.25 ml of 3-aminopropyltriethoxysilane ethanol solution with a volume ratio of 1:49 to 50 ml of 0.4 mg / ml polystyrene ethanol solution. Magnetic stirring, reaction 2 h.

[0044] At room temperature, after separating and washing the aminated polystyrene microspheres, they were dispersed in glutaraldehyde aqueous solution dilut...

Embodiment 3

[0047] Add 5 ml of water and 25 ml of absolute ethanol into a 50 ml round bottom flask, then add 1.5 ml of tetraethyl orthosilicate (TEOS) drop by drop under vigorous stirring, and mix 1.6 One ml of ammonia water and the same volume of water were added at once, stirred and reacted at room temperature for 6 hours, and the product obtained after separation and cleaning was silica microspheres. Observation by transmission electron microscope shows that the particle size of silica microspheres is about 330 nm, such as Figure 7 shown.

[0048] Add 0.25 ml of an ethanol solution of 3-aminopropyltriethoxysilane with a volume ratio of 1:49 to 50 ml of a 0.4 mg / ml ethanol solution of silica microspheres at room temperature. Magnetic stirring, reaction 2 h.

[0049] At room temperature, after separating and washing the aminated silica microspheres, they were dispersed in glutaraldehyde aqueous solution diluted with phosphate buffer solution at pH=7.4 (5 ml of 25% glutaraldehyde stock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com