Metal-porphyrin polymer catalyst and preparation and application thereof

A technology of porphyrin polymers and metals, which is applied in the field of metal-porphyrin polymer catalysts and its preparation and application, can solve the problems of high requirements for industrial equipment, low catalyst efficiency, and expensive oxidants, and achieve high selectivity and low cost. Low, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

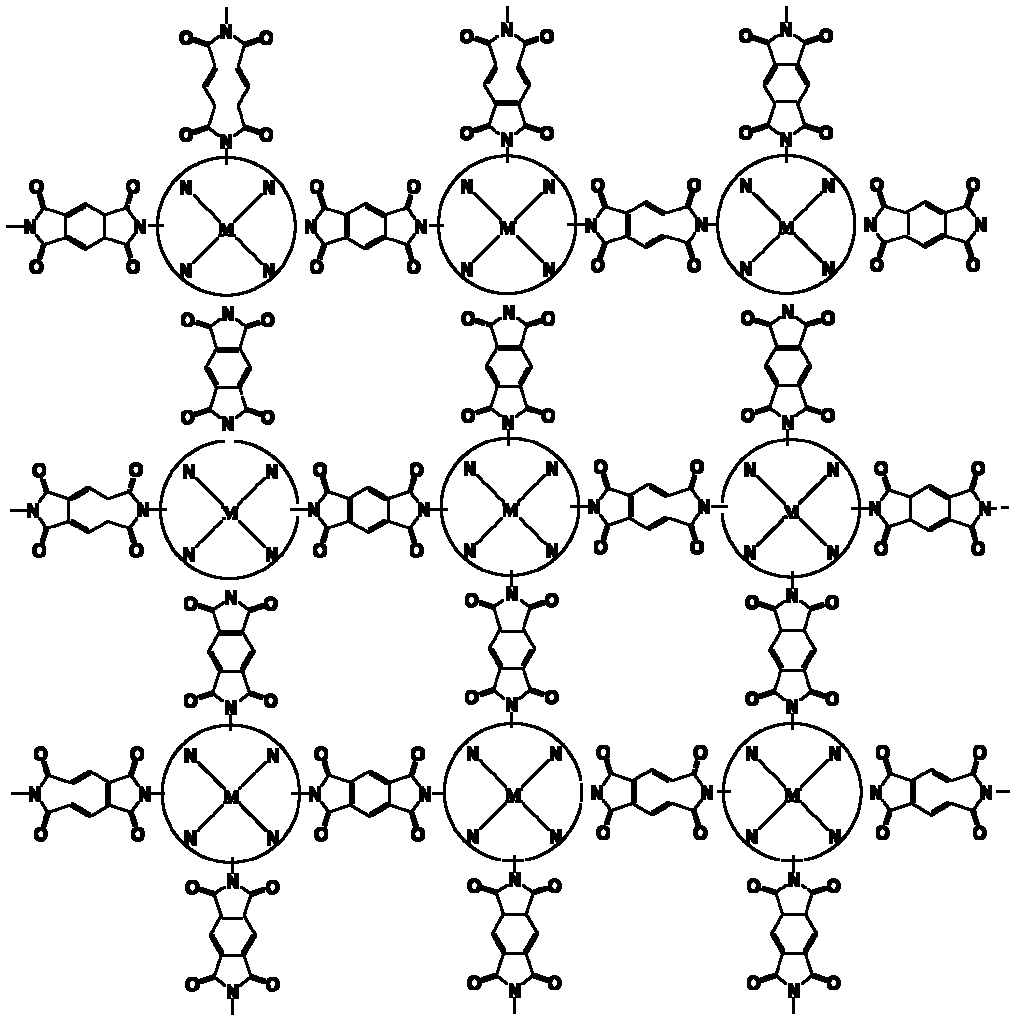

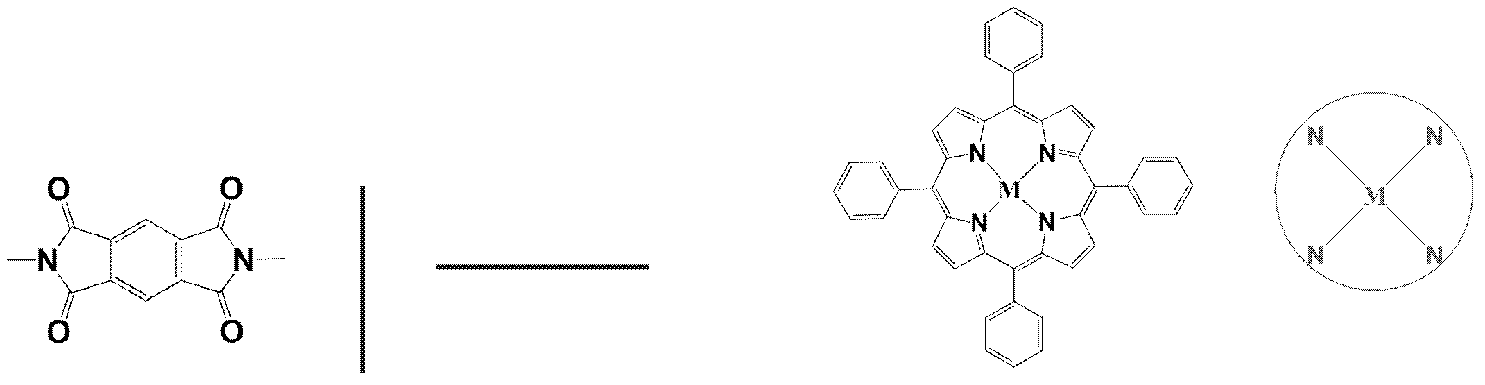

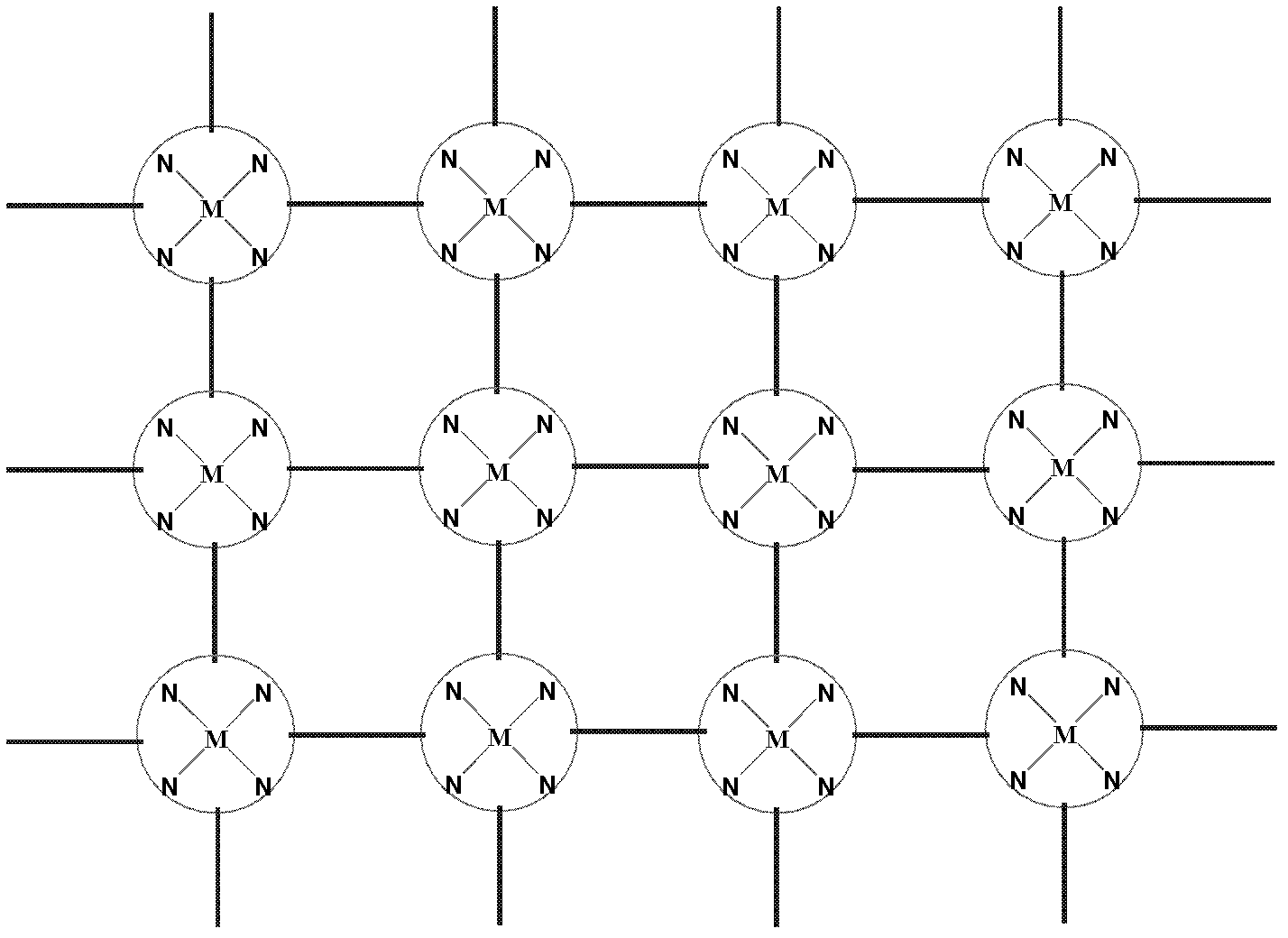

[0023] The preparation method of metal-porphyrin polymer catalyst of the present invention is as follows:

[0024] TAPP (tetraaminophenylporphyrin) was synthesized according to the literature method. TAPP and pyromellitic anhydride were reacted at room temperature for 24 hours with NMP (N-methylpyrrolidone) as a solvent, pyridine and acetic anhydride as catalysts, and then at 60° C. for 12 hours under nitrogen protection. The obtained solution was poured into methanol solvent to precipitate porphyrin polymer, filtered with suction, washed with methanol and water respectively until the filtrate was colorless, and dried. Metal ions (Ru 3+ , Pd 2+ , Fe 2+ , Mn 2+ , Cu 2+ ,Co 2+ , Ni 2+ or Zn 2+ ) and the porphyrin polymer were dissolved in NMP according to the molar ratio of 5:1, and after reacting for 24 hours at 60° C., poured into methanol solvent to separate out the metal-porphyrin polymer material. After drying, the metal-porphyrin polymer material of the present in...

Embodiment 1

[0029] TAPP (tetraaminophenylporphyrin) was synthesized according to literature. TAPP (1mmol) and pyromellitic anhydride (2.1mmol) were reacted at room temperature for 24 hours with 40mL NMP (N-methylpyrrolidone) as solvent, pyridine (2mL) and acetic anhydride (4mL) as catalyst under nitrogen protection , then reacted at 60°C for 12 hours, then poured the resulting solution into a methanol solvent to precipitate a porphyrin polymer, filtered it with suction, washed it with methanol and water until the filtrate was colorless, and dried it; Mn 2+ Dissolve in NMP with porphyrin polymer according to the molar ratio of 5:1, react at 60° C. for 24 hours, pour into methanol solvent to precipitate metal-porphyrin polymer material. Then the metal-porphyrin polymer material was characterized by means of powder X-ray diffraction, thermogravimetric and IR.

Embodiment 2

[0031] Catalyst activity evaluation was carried out in a simple photocatalytic reaction device with magnetic stirring. 0.1 mmol of methyl phenyl sulfide, 5 mL of acetonitrile, and 0.01 mmol of manganese porphyrin polymer catalyst were sequentially added into a glass reactor. Under the condition of 100W mercury lamp irradiation and oxygen as the oxygen source, after reacting at room temperature for 4 hours, the reaction product was filtered, extracted, dried, and passed through a micro-silica gel column, and the conversion rate of methyl phenyl sulfide was analyzed by gas chromatography to be 99.3 % and the selectivity to the product methylphenyl sulfoxide was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com