Preparation method of mesoporous silica nanometer composite flame retardant

A mesoporous silica and nano-composite technology, which is used in the manufacture of tools, wood processing appliances, impregnated wood, etc., can solve the problems of introducing unfavorable flame retardants into pores and limited loading, and achieve excellent synergistic flame retardant effect, process Safe, good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

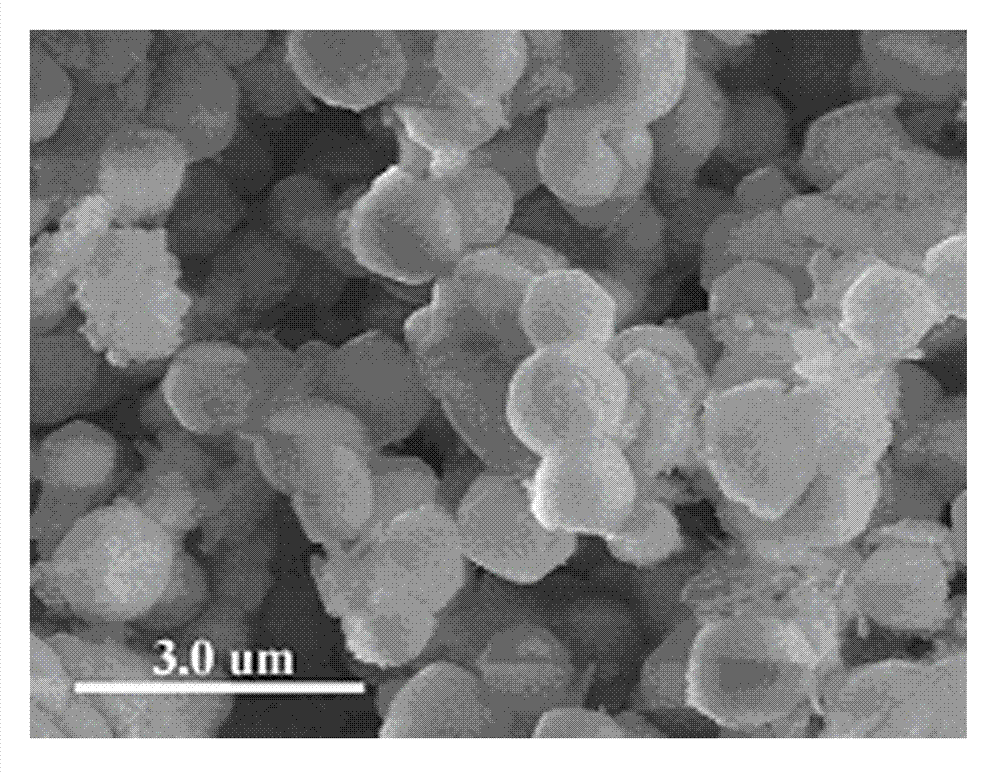

[0015] Dissolve 16.8 g of dodecyltrimethylammonium bromide in a mixed solution of 1.26L of methanol and 3.0L of water, add 30ml of 1M NaOH solution, and stir well. Then, gradually add 24.8g tetraethyl orthosilicate, react at room temperature for 8 hours, transfer to a polytetrafluoroethylene bottle at 95°C and seal and age for 24 hours, filter to obtain a white powder, and dry it in vacuum to obtain mesoporous silica nanoparticles. Particles: Dissolve 8.2g of ammonium polyphosphate in 80ml of water, then add 10.0g of the above-mentioned mesoporous silica particles, stir at 60°C for several hours, evaporate and remove water, then dry in vacuum at 105°C for 8h, grind and sieve, the obtained product is Mesoporous silica nanocomposite flame retardant.

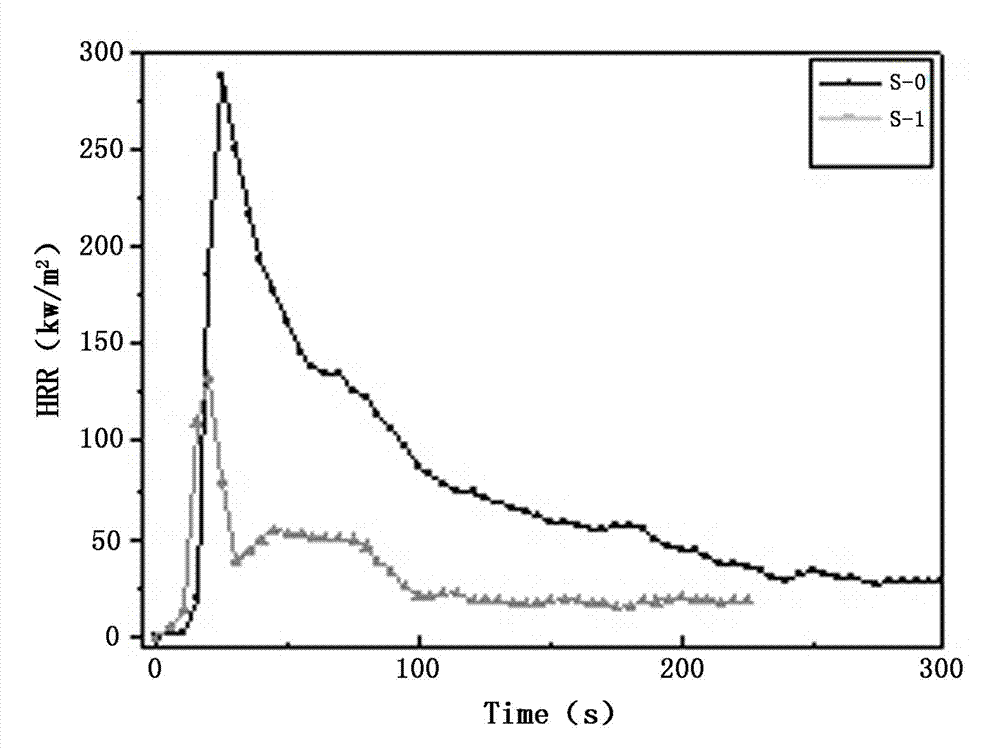

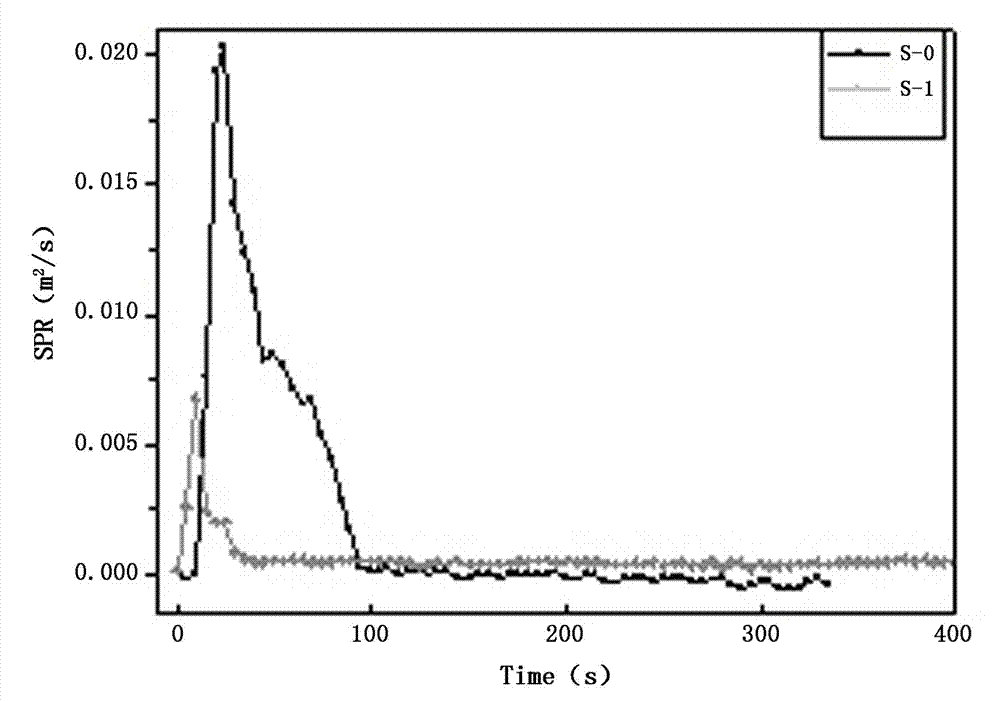

[0016] Weigh 2.0 g of the mesoporous silica nanocomposite flame retardant prepared in Example 1 and 20 g of dry poplar wood powder, grind them thoroughly in an agate mortar, and conduct a CONE experiment with a Stanton Redcroft con...

Embodiment 2

[0019] Dissolve 10.0 g of cetyltrimethylammonium bromide in 4.8 L of water, add 70 ml of 1M NaOH solution, and stir well. Then, 57.5ml tetraethyl orthosilicate was added dropwise, reacted at 80°C for 2h, transferred to a polytetrafluoroethylene bottle at 100°C and aged for 24h, filtered to obtain a white powder, and dried in vacuum to obtain mesoporous silica Nanoparticles: Weigh 6.2 g of dimethyl methylphosphonate, disperse in 120 ml of absolute ethanol, then add 10.0 g of mesoporous silica prepared by the above process, stir for several hours at 50 ° C, evaporate to remove ethanol. Then vacuum Dry at 105°C for 8 hours, grind and sieve to obtain a mesoporous silica nanocomposite flame retardant.

[0020] Weigh 2.0 g of the mesoporous silica nanocomposite flame retardant prepared in Example 2 and 20 g of dry poplar wood powder, grind them thoroughly in an agate mortar, and conduct a CONE experiment with a Stanton Redcroft cone calorimeter. In order to make the experimental te...

Embodiment 3

[0023] Disperse 20 g of polystyrene microspheres in a mixture of 7.5 L of ethanol and 0.5 L of deionized water, then add 0.38 L of 28% ammonia solution, and ultrasonically disperse for 15 minutes. Add 40ml of a mixture of ethyl orthosilicate and octadecyltrimethoxysilane (molar ratio 4:1) dropwise, stir vigorously, react at room temperature for 8 hours, filter and dry to obtain a white solid powder, and then 500 Calcined at ℃ for 7 hours to obtain mesoporous silica hollow spheres; take 10g of ammonium polyphosphate and dissolve it in 160ml of water, then add 8.0g of the above-mentioned mesoporous silica hollow spheres, stir at 60℃ for several hours, and evaporate to remove water. Then Vacuum drying at 105° C. for 8 hours, grinding and sieving, and the obtained product is a mesoporous silica nanocomposite flame retardant.

[0024] Put the low-density polyethylene (LDPE) into the open mixer, knead at 120-130°C for 15 minutes, add a compound flame retardant with a mass ratio of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com