Process for production of cadaverine

A cadaverine and microbial technology, applied in the field of cadaverine preparation, can solve the problems of no increase in cadaverine yield, generation of by-product lysine, increased burden of cadaverine refining, etc., and achieve the goal of reducing load and increasing sugar yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] The following examples and comparative examples are listed to describe the present invention in detail. In addition, unless otherwise specified, all culture media, agar media, and culture media used in Examples and Comparative Examples are subjected to general sterilization operations (such as 121 ° C, 30 minutes of high-pressure steam sterilization, or 0.45 μm filter), use in the sterilized state.

[0074] (HPLC analysis method for cadaverine and lysine concentration)

[0075] Column used: CAPCELL PAK C18 (Shiseido)

[0076] Mobile phase: 0.1% (w / w) phosphoric acid aqueous solution: acetonitrile=4.5:5.5

[0077] Detection: UV360nm

[0078] Sample pretreatment: Add 25 μl of 1,4-butanediamine (0.03M) as an internal standard to 25 μl of analysis sample, add 150 μl of sodium bicarbonate (0.075M) and 2,4-dinitrofluorobenzene (0.2M ) in ethanol and incubated at 37°C for 1 hour. 50 μl of the above reaction solution was dissolved in 1 ml of acetonitrile, then centrifuged ...

reference example 1

[0079] Reference Example 1 (Creation of Corynebacterium glutamicum capable of producing lysine)

[0080] In order to produce Corynebacterium glutamicum capable of synthesizing lysine which is a precursor of cadaverine, lysine-producing bacteria were produced by introducing effective mutations into aspartokinase. Corynebacterium glutamicum AK-1 strain (hereinafter referred to as AK-1 strain) was produced by the method described in Apppl. Microbiol. Biotechnol., (2002), 58, p.217-223. The aspartokinase of this strain can relieve the feedback inhibition caused by lysine and threonine. Therefore, lysine can be synthesized by cultivation.

Embodiment 1

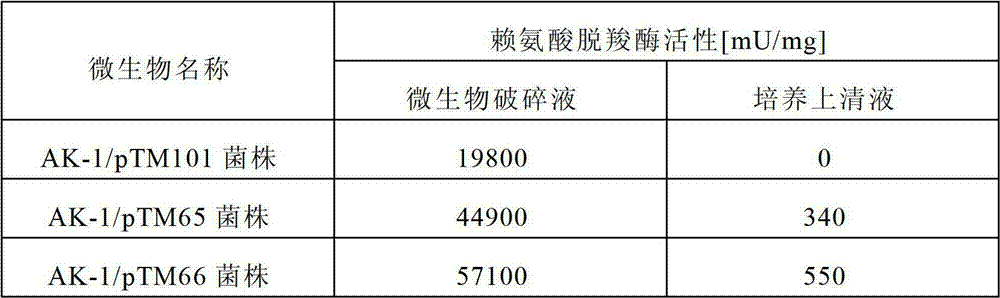

[0082] Example 1 (Creation of Corynebacterium glutamicum secreting lysine decarboxylase extracellularly) (Part 1: Utilization of Tat pathway)

[0083] (1) Cloning of HOM gene

[0084] Homoserine dehydrogenase was selected as the locus for introducing the lysine decarboxylase gene. The gene corresponding to the 300 amino acid region from the N-terminal of the HOM gene was cloned. Oligonucleotide primers (SEQ ID NO: 1 and NO: 2) were synthesized with reference to the base sequence of the HOM gene (Accession No: BA000036) registered in the database (GenBank). The genomic DNA solution prepared according to conventional methods from Corynebacterium glutamicum ATCC13032 was used as an amplification template, and 0.2 μl of each was put into a 0.2ml microcentrifuge tube, and various reagents were added: 20 pmol of each primer, pH8.0 Tris hydrochloride buffer (20 mM), potassium chloride (2.5 mM), gelatin (100 μg / ml), each dNTP (50 μM), and LATaq DNA polymerase (2 units) (manufactured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com