Preparation method of high-grade borate type automobile brake fluid

A technology for automobile braking and borate esters, which is used in the preparation of ethers, preparation of ethers from alkylene oxide, chemical instruments and methods, etc. It can solve the problem that the product viscosity is too large to meet the DOT5.1 standard, limit the boiling point range of brake fluid, and synthesize The problem of low yield of cyclic boronate esterification is to meet the requirements of product quality and appearance, to achieve high value-added utilization, and to achieve good synergistic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

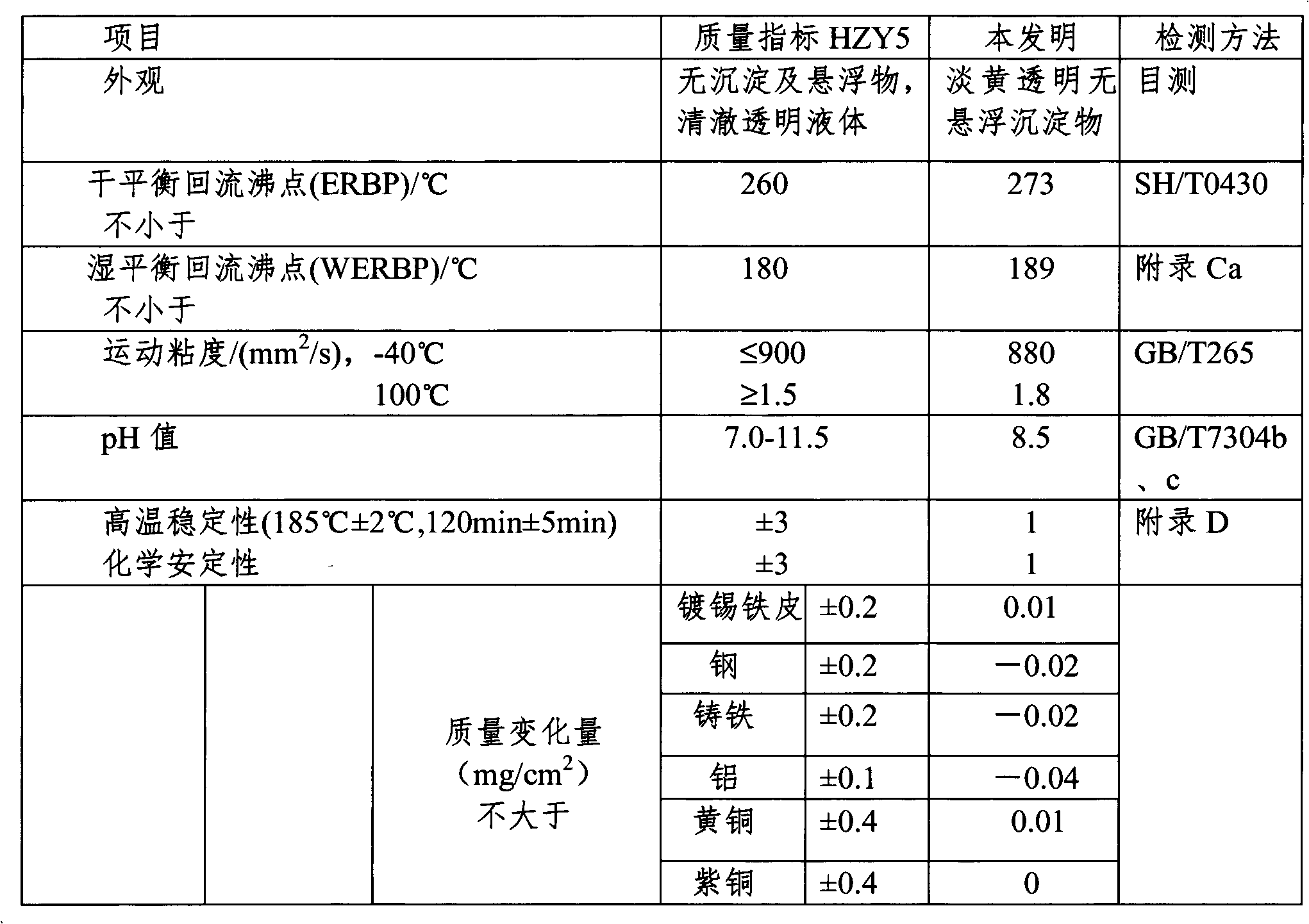

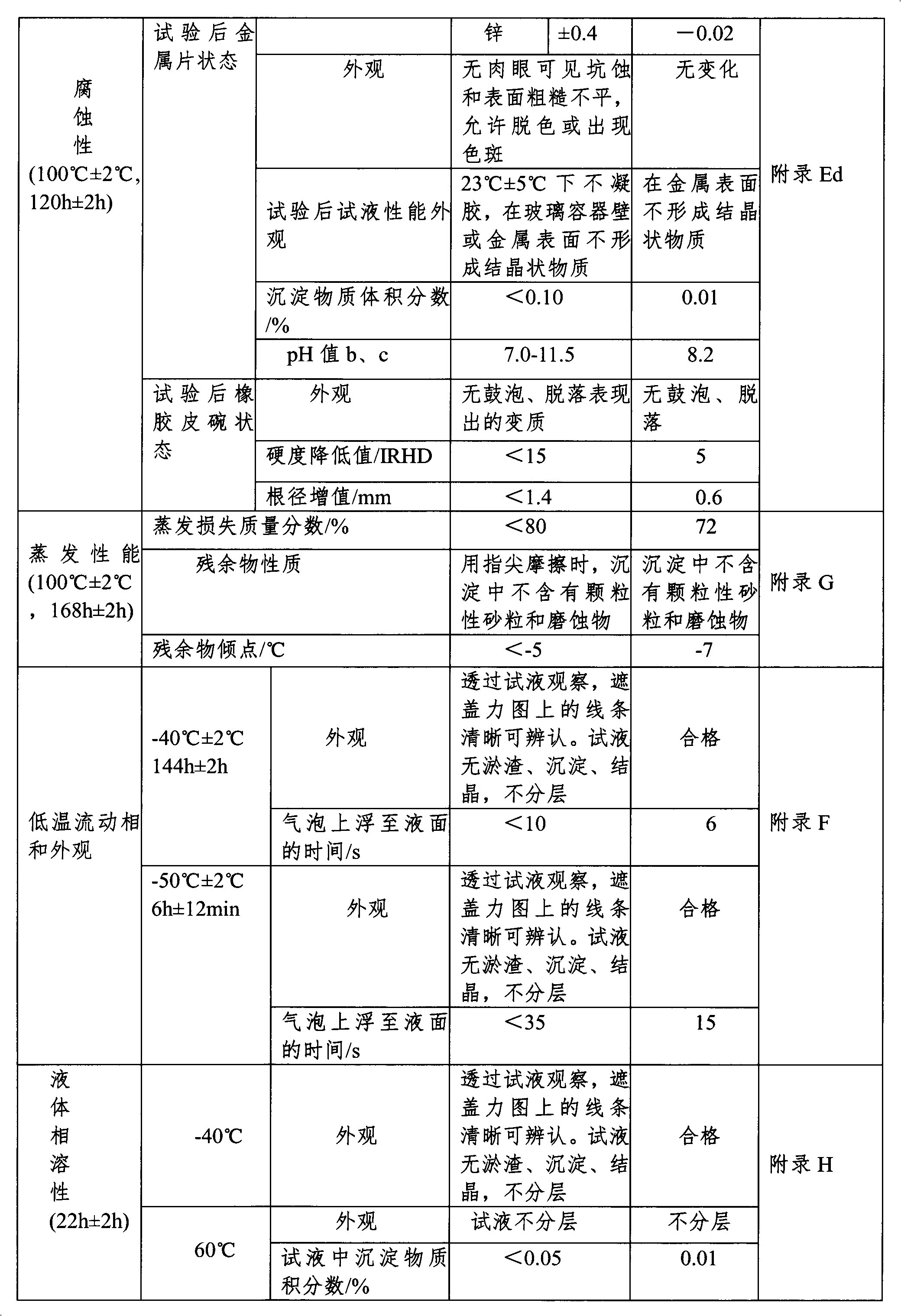

Image

Examples

Embodiment

[0033] (1) Take 30g of n-propanol, 174g of propylene oxide, and 0.5g of sodium hydroxide and put them into the autoclave, blow in nitrogen to exhaust the air in the autoclave, pressurize to 0.3MPa, heat to 170°C, and maintain at this temperature React for 1.5 hours, the pressure rises to 1.9MPa and then drops rapidly, and the temperature gradually rises to 270°C and then gradually drops. When the pressure drops to 0.4MPa, the polymerization is completed, stop heating, add lactic acid after cooling to adjust the pH value to 7, and obtain a light yellow color polypropanol propyl ether;

[0034] (2) Pour polypropanol propyl ether into a 500ml beaker, add 1g of coal-based activated carbon that has been pretreated, stir and adsorb for 2h, and filter under reduced pressure with a Buchner funnel;

[0035] (3) Put the filtrate at 3.0×10 -2 Carry out vacuum vacuum distillation under the pressure condition of MPa, collect the oligomeric alcohol ether fraction before 170 °C during the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com