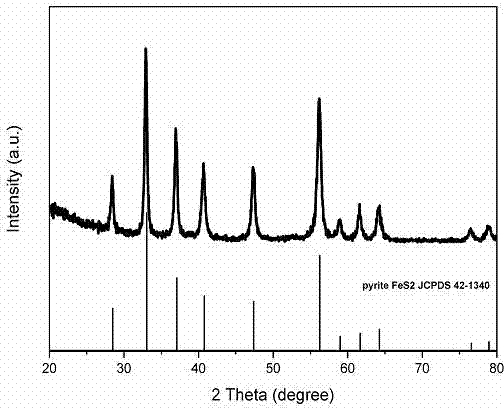

Preparation method of pyrite-type ferrous disulfide nanoscale single-crystal semiconductor material

A technology of ferrous disulfide and pyrite type, which is applied in the direction of ferric sulfide, polycrystalline material growth, chemical instruments and methods, etc., to achieve the effects of wide selection range, simple preparation process and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

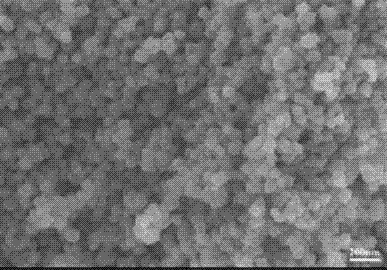

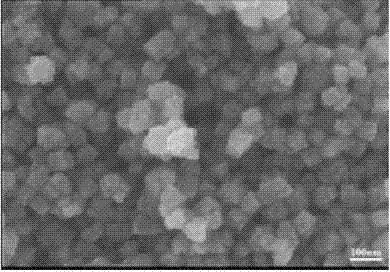

Embodiment 1

[0043] Example 1 A preparation method of pyrite type ferrous disulfide nano single crystal semiconductor material, comprising the following steps:

[0044] ⑴Mix the iron source—ferrous chloride with a concentration of 0.05 mol / L and trioctylphosphine oxide (TOPO) at a molar ratio of 1:2, and dissolve in oleylamine, stir and pass the purity to 98.5% After removing oxygen from the above argon or nitrogen gas, an iron source precursor is obtained.

[0045] Among them: the mass volume ratio (g / ml) of iron source to oleylamine is 1:100.

[0046] (2) Heating the iron source precursor to 120° C. in an oil bath and stirring for 1.5 hours to obtain an iron source solution.

[0047] (3) Dissolve the sulfur source—sulfur powder in oleylamine, and after stirring and passing argon or nitrogen with a purity of more than 98.5% to remove oxygen, obtain a sulfur source solution.

[0048] Among them: the mass volume ratio (g / ml) of sulfur source to oleylamine is 1:50.

[0049] (4) Heati...

Embodiment 2

[0053] Example 2 A preparation method of pyrite type ferrous disulfide nano single crystal semiconductor material, comprising the following steps:

[0054] ⑴Mix the iron source—ferrous chloride with a concentration of 0.5 mol / L and trioctylphosphine oxide (TOPO) at a molar ratio of 1:6, and dissolve in oleylamine, stir and pass the purity to 98.5% After removing oxygen from the above argon or nitrogen gas, an iron source precursor is obtained.

[0055] Among them: the mass volume ratio (g / ml) of iron source to oleylamine is 1:300.

[0056] (2) Heating the iron source precursor to 170° C. in an oil bath and stirring for 0.5 hours to obtain an iron source solution.

[0057] (3) Dissolve the sulfur source—thioacetamide in oleylamine, and after stirring and passing argon or nitrogen with a purity of more than 98.5% to remove oxygen, obtain a sulfur source solution.

[0058] Among them: the mass volume ratio (g / ml) of sulfur source to oleylamine is 1:100.

[0059] (4) Heating...

Embodiment 3

[0063] Example 3 A preparation method of pyrite type ferrous disulfide nano single crystal semiconductor material, comprising the following steps:

[0064] ⑴Mix the iron source—ferrous chloride with a concentration of 0.25 mol / L and trioctylphosphine oxide (TOPO) at a molar ratio of 1:4, and dissolve in oleylamine, stir and pass the purity to 98.5% After removing oxygen from the above argon or nitrogen gas, an iron source precursor is obtained.

[0065] Among them: the mass volume ratio (g / ml) of iron source and oleylamine is 1:200.

[0066] (2) Heating the iron source precursor to 140° C. in an oil bath and stirring for 1 hour to obtain an iron source solution.

[0067] (3) Dissolve the sulfur source—L-cysteine monohydrate hydrochloride in oleylamine, and after stirring and passing argon or nitrogen with a purity of more than 98.5% to remove oxygen, obtain a sulfur source solution.

[0068] Among them: the mass volume ratio (g / ml) of sulfur source to oleylamine is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com