Attapulgite carrier catalyst for oxidation of elemental mercury in flue gas and preparation method thereof

An oxidation catalyst and attapulgite technology, which is applied in the field of elemental mercury oxidation catalyst and its preparation, can solve the problems of increased system energy consumption and operating costs, little attention to low-temperature catalytic performance, difficulty in popularization and practical application, etc., to achieve improved The effect of catalytic oxidation efficiency, avoidance of preheating energy consumption, and improvement of dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

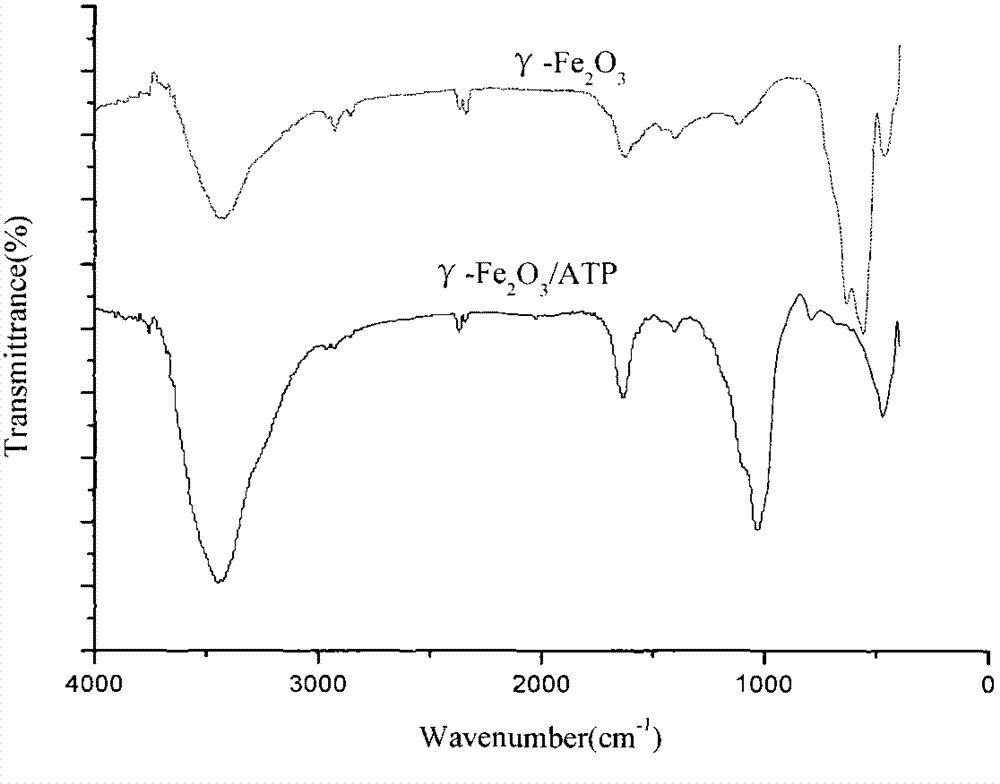

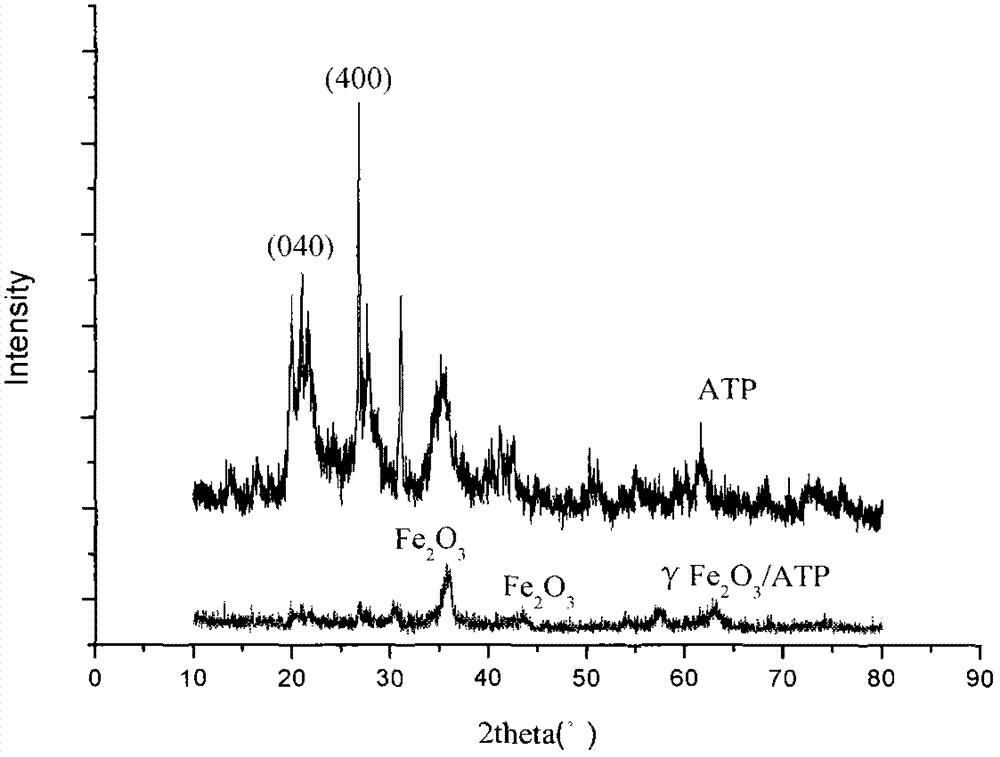

[0024] Accurately weigh 10g of ferric nitrate, dissolve it in 40ml of ethylene glycol solution, stir at a constant speed for 20 minutes under magnetic stirring until the ferric nitrate is completely dissolved, then stir vigorously in an oil bath at 70°C and full reflux for 6 to 7 hours to form γ-Fe 2 o 3 Sol. Then add 4 g of Fe-modified attapulgite powder, stir vigorously at 60° C. for 8 to 12 hours, and age for one day. Filter and wash with distilled water 5-6 times, then vacuum-dry at 55°C for one day, and grind into powder. Calcinate at 300°C for 2-4 hours, grind again and pack into bags. Preparation of γ-Fe with Fe-modified attapulgite as carrier 2 o 3 Doped flue gas elemental mercury oxidation catalyst.

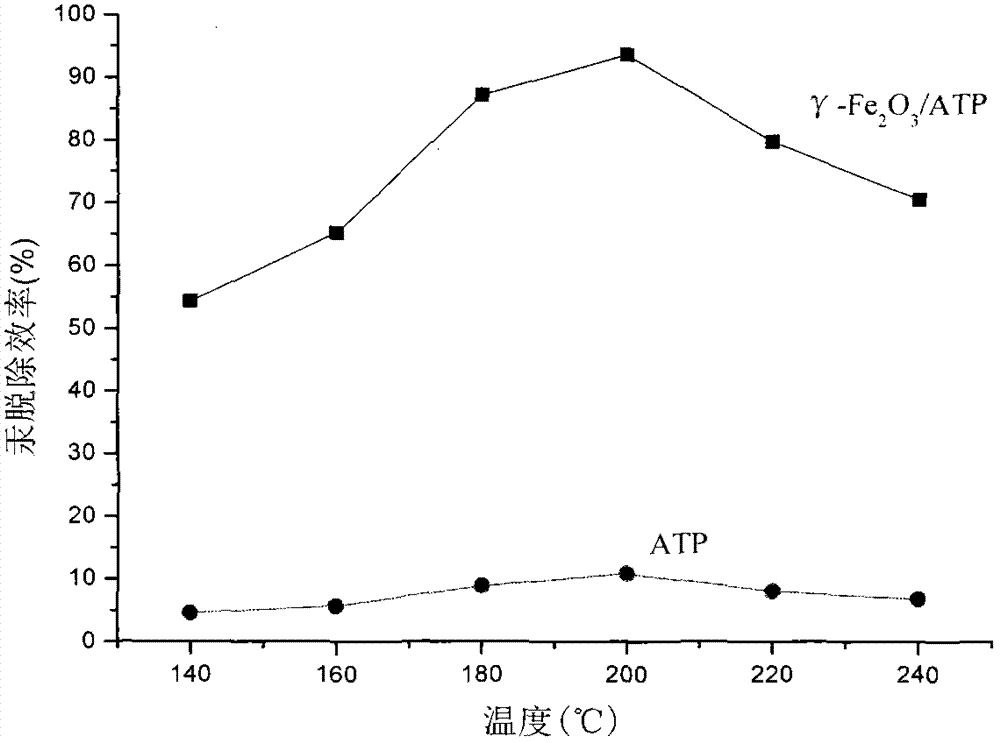

[0025] Take by weighing 0.5g above-mentioned catalyzer, in its tubular fixed-bed reactor, pass into composition and be 6% O 2 , 12% CO 2 , 300ppm NO, 50ppm Cl 2 , 100ml / min N2 (as a carrier of mercury vapor), zero-valent mercury 20±1μg / m 3 simulated smoke. The...

Embodiment 2

[0027] A certain amount of cerous nitrate (3mol / L) was slowly added into a certain concentration of citric acid aqueous solution (0.2mol / L) (n(Ce 3+ ) / n(C 6 h 8 (O7)=1:3), after it is completely dissolved, stir at 65°C for 6-8 hours to form CeO 2 Sol. Then add 4 g of Fe-modified attapulgite powder, stir for 3 hours, filter, wash with distilled water 5-6 times, then vacuum-dry at 55°C for one day, calcinate at 200°C for 3 hours, and grind. Preparation of CeO with Fe-modified attapulgite as carrier 2 Doped flue gas elemental mercury oxidation catalyst.

[0028] Take by weighing 0.5g above-mentioned catalyzer, in its tubular fixed-bed reactor, pass into composition and be 6% O 2 , 12% CO 2 , 300ppm NO, 50ppm Cl 2 , 100ml / min N 2 (as a carrier of mercury vapor), zero-valent mercury 20±1μg / m 3 simulated smoke. The temperature is 200°C and the space velocity is 38000h -1 Under the condition of , when the catalyst reaches the stable catalytic stage, the oxidation efficienc...

Embodiment 3

[0030] First take 24mL of isopropanol and 5.4mL of acetic acid and stir evenly for 10min to obtain a mixed solution. Weigh 2g of tungsten chloride (WCl 6 ) into the mixed solution, the solution immediately becomes turbid and dark blue, stirring continuously to form a uniform dark blue HWO 3 , then add 0.6 mL of H 2 o 2 , wait for the solution to form a clear yellow-green to get WO 3 Sol. Then add 4 g of Fe-modified attapulgite powder, stir for 3 hours, filter, wash with distilled water 5-6 times, then vacuum-dry at 55°C for one day, calcinate at 300°C for 2-4 hours, and grind. Preparation of WO with Fe-modified attapulgite as carrier 3 Doped flue gas elemental mercury oxidation catalyst.

[0031] Take by weighing 0.5g above-mentioned catalyzer, in its tubular fixed-bed reactor, pass into composition and be 6% O 2 , 12% CO 2 , 300ppm NO, 50ppm Cl 2 , 100ml / min N 2 (as a carrier of mercury vapor), zero-valent mercury 20±1μg / m 3 simulated smoke. The temperature is 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com