Method for producing potassium gluconate through fermentation of Aspergillus niger

A fermentation technology of potassium gluconate and Aspergillus niger, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of lower glucose conversion rate, low sugar concentration at the beginning of fermentation, and increase catalyst consumption, etc., to achieve Facilitate extraction, high concentration, and reduce steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

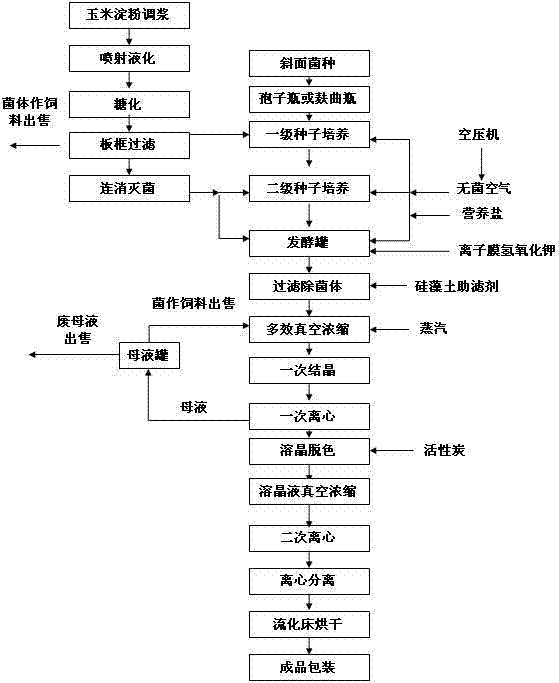

Image

Examples

Embodiment Construction

[0027] 1. Preparation of glucose solution:

[0028] 1) Mixing:

[0029] According to the ratio of starch and starchy raw materials to water 1:1-2 (W / V), add starch into the slurry tank, adjust the pH value to 6.0-6.5 with sulfuric acid or KOH, and dry at 8-20u / g Add high-temperature α-amylase to the starch; stir for 20-30 minutes.

[0030] 2) Jet liquefaction:

[0031] Using a jet liquefaction process, turn on the starch pump to control the slurry for 5-50m 3 / h flow into the ejector: the feed pressure is greater than the steam pressure 0.02-0.04Mpa, the temperature is controlled at 100-115 ° C, the slurry and steam are quickly mixed into the pressure tank, maintained for 5-6 minutes, and then into the flash tank. After the material temperature drops to 95--98°C, it enters the maintenance tank and maintains for 90-120 minutes. After passing the iodine inspection, the material temperature is reduced to 62--64°C through the heat exchanger and enters the pH mixing tank.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com