Fly-ash fiber heat-insulation acoustic board and preparation method thereof

A technology of fly ash fiber and sound-absorbing panels, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as poor sound absorption and heat insulation, mildew, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Fly ash fiber 92.0wt%

[0046] Polyvinyl acetate emulsion (solid content 48wt%) 5.0wt%

[0047] Aqueous paraffin emulsion (solid content 30wt%) 3.0wt%

[0048] Prepare the fly ash fiber into a water-based slurry with a concentration of 2wt%, then add polyvinyl acetate emulsion and water-based paraffin emulsion, stir and disperse evenly, pour it into a mold, squeeze to remove excess water, and obtain a wet billet , dried naturally to obtain fly ash fiber insulation and sound-absorbing panels. The fly ash fiber thermal insulation and sound-absorbing board is obtained after cutting and removing edges, planing, spraying, drying and other procedures.

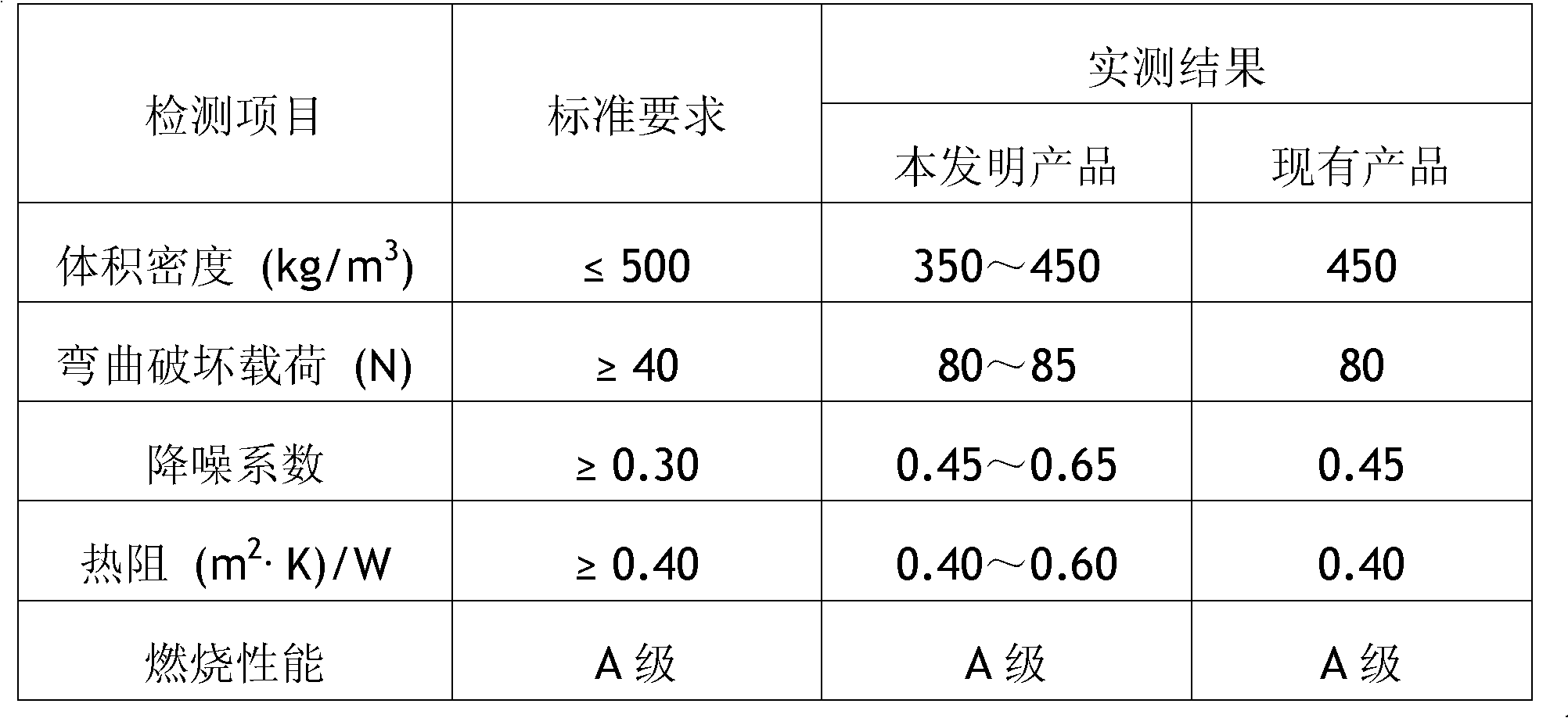

[0049] Its volume density, bending failure load, noise reduction coefficient, thermal resistance, and combustion performance are all tested according to the JC / T670-2005 standard, and the result is: volume density 350kg / m 3 , bending failure load 80N, noise reduction coefficient 0.60, thermal resistance 0.60(m 2 ·K) / W, com...

Embodiment 2

[0052] Vinyl acetate-ethylene copolymer emulsion (solid content 55wt%) 4.0wt%

[0053] Polyacrylamide cationic surfactant (cationicity 40%) 2.5wt%

[0054]Prepare the fly ash fiber into a water-based slurry with a concentration of 1.5wt%, then add vinyl acetate-ethylene copolymer emulsion and polyacrylamide cationic surfactant, stir and disperse evenly, pour it into a mold, and squeeze to remove excess moisture content to obtain a wet billet. During the drying process, embossing and other treatments are carried out on the wet slab, and the fly ash fiber insulation and sound-absorbing board can be obtained after drying. Its volume density, bending failure load, noise reduction coefficient, thermal resistance, and combustion performance are all tested according to the JC / T 670-2005 standard, and the result is: volume density 380kg / m 3 , bending failure load 82N, noise reduction coefficient 0.45, thermal resistance 0.55(m 2 ·K) / W, combustion per...

Embodiment 3

[0057] Waterborne polyurethane (solid content 35wt%) 10.0wt%

[0058] Lauryl dimethyl betaine 2.1wt%

[0059] The fly ash fiber is formulated into a water-based slurry with a concentration of 2.5wt%, then water-based polyurethane (solid content 35wt%) is added, and dodecyl dimethyl betaine is added, and it is poured into the mold after stirring and dispersing evenly , pressed into shape, after natural drying, through cutting, planing, spraying, drying and other procedures, and finally get the fly ash fiber insulation sound-absorbing board. Its bulk density, bending failure load, noise reduction coefficient, thermal resistance, and combustion performance are all tested according to the JC / T 670-2005 standard, and the result is: bulk density 400kg / m 3 , bending failure load 85N, noise reduction coefficient 0.65, thermal resistance 0.55(m 2 ·K) / W, combustion performance Class A non-combustible.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bending failure load | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com